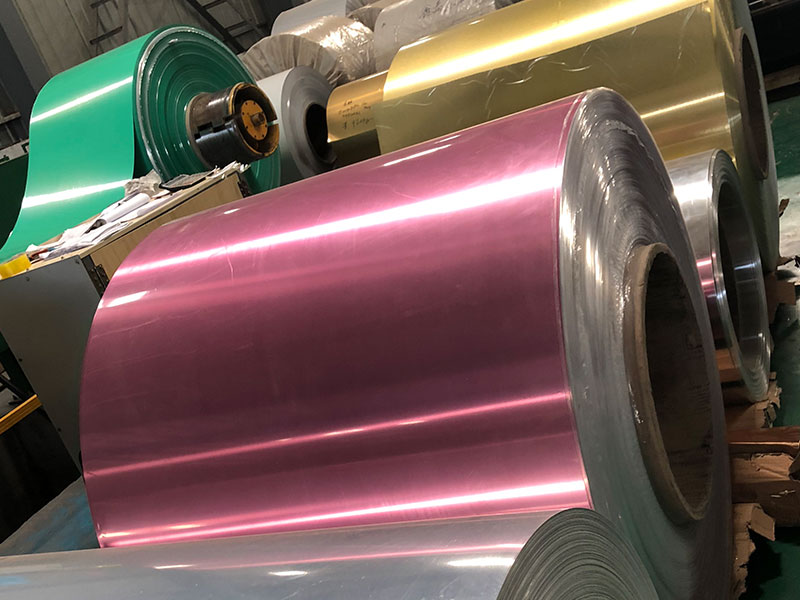

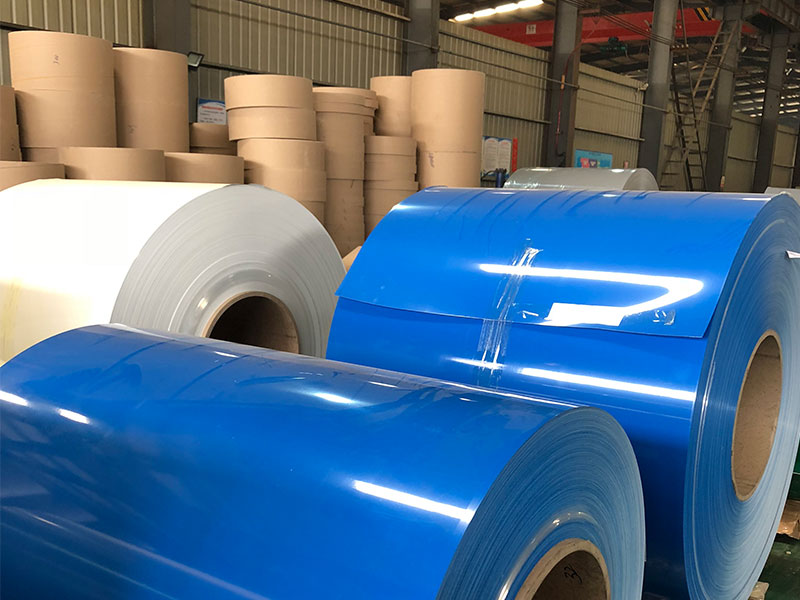

1100 3003 5052 5083 Aluminum coil for roofing

Aluminum coils are essential components in the construction and manufacturing sectors, particularly for roofing applications. Among the various grades, 1100, 3003, 5052, and 5083 aluminum coils are renowned for their unique properties and wide applicability.

Features

- Lightweight: Aluminum coils provide significant weight savings compared to traditional materials.

- Corrosion Resistance: Excellent natural resistance to corrosion, which is ideal for exposed environments.

- Ductility: High freedom to bend and shape aluminum without cracking.

- Thermal Conductivity: Quite effective in temperature management due to high thermal conductivity.

- Recyclability: Fully recyclable, promoting sustainability within construction practices.

Applications

- Roofing Systems: Due to the lightweight and durable nature of aluminum, it is frequently used in residential and commercial roofing.

- Panels and Sheeting: Cosmetic alternatives to traditional roofing due to the finish properties.

- Insulation Covers: Aluminum reflective properties make it advantageous in various insulation setups.

- Architectural Elements: Design flexibility allows for creative roster designs, enhancing aesthetic appeal.

Technical Specifications

The technical specifications of the aluminum coils vary by grade, necessitating distinct treatment concerning physical and mechanical properties. Below are detailed explanatory tables breaking down the specifics.

Chemical Composition

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) |

|---|---|---|---|---|---|---|---|---|

| 1100 | 0.1 | 0.5 | 0.05 | 0.05 | 0.05 | 0.05 | 0.1 | 0.02 |

| 3003 | 0.2 | 0.7 | 0.2 | 1.0 | 0.1 | 0.1 | 0.1 | 0.03 |

| 5052 | 0.25 | 0.4 | 0.2 | 0.25 | 2.2 | 0.15 | 0.1 | 0.025 |

| 5083 | 0.4 | 0.4 | 0.1 | 0.15 | 3.0 | 0.05 | 0.25 | 0.1 |

Mechanical Properties

| Alloy | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 1100 | 70 | 125 | 16 |

| 3003 | 110 | 200 | 20 |

| 5052 | 200 | 250 | 12 |

| 5083 | 260 | 310 | 10 |

Alloy Tempering Conditions

| Alloy | Tempers | Nomenclature Used | Hardness (HB) |

|---|---|---|---|

| 1100 | H14 | Half Hardened | 40 |

| 3003 | H14 | Work-hardened | 48 |

| 5052 | H32 | Solution Heat Treated | 73 |

| 5083 | H321 | Partially Strain Hardened | 78 |

https://www.aluminumplate.net/a/1100-3003-5052-5083-aluminum-coil-for-roofing.html