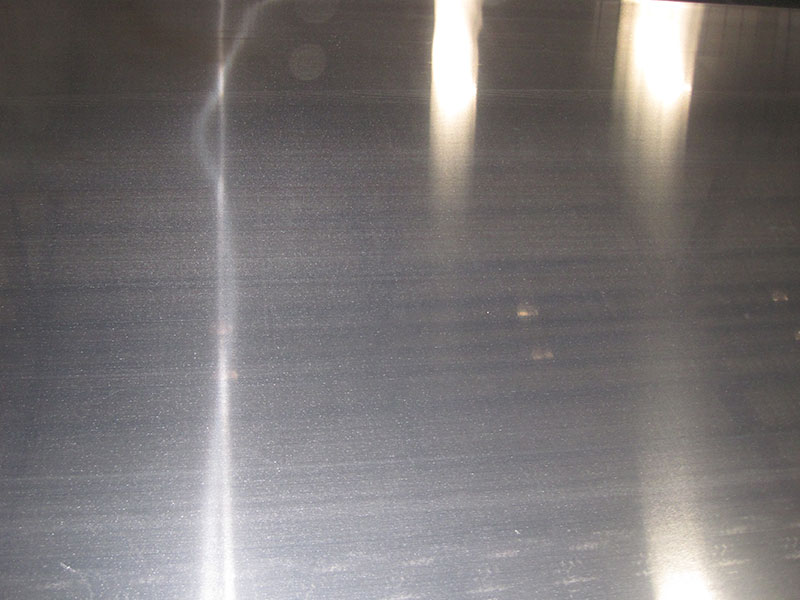

Painted Aluminum Sheet 3105 H14

In the world of construction, architecture, and design, choosing the right material for exterior and interior applications is more than just an aesthetic decision—durability, ease of handling, and long-term performance weigh heavily. Among the many options available, Painted Aluminum Sheet 3105 H14 distinguishes itself as a smart choice that balances practical properties with a polished finish.

3105 H14 Alloy and Temper

At its core, 3105 is an aluminum alloy predominantly used for thin sheets. Its primary ingredient is aluminum with small percentages of manganese and magnesium, creating a mix that enhances strength, corrosion resistance, and facilitates painting processes.

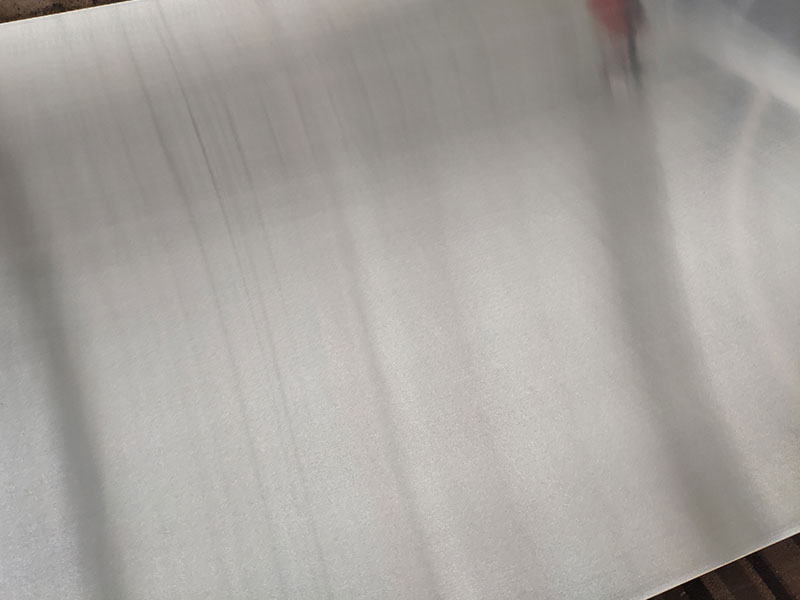

Working with painted Aluminum Sheet 3105 H14, I've found its H14 temper to be a double-edged sword. The relatively soft nature makes it exceptionally formable, crucial for complex shapes in applications like automotive parts or appliance casings. However, this softness also necessitates careful handling during the painting process to avoid scratching or marring the surface before the paint fully cures. We've seen instances where improper handling during stamping or bending led to significant rework, highlighting the need for precise tooling and operator training. Furthermore, the 3105 alloy itself possesses good corrosion resistance, but the integrity of the paint system is paramount. Any compromise in the paint’s adhesion or thickness can rapidly expose the underlying aluminum to environmental factors, leading to premature degradation and potentially costly product recalls.

One recurring challenge involves optimizing the paint curing process to ensure both adhesion and flexibility. The specific paint formulation interacts differently with the 3105 H14's surface compared to harder aluminum alloys. We've experimented with variations in curing temperatures and times to balance the need for a robust, durable finish with minimizing the risk of paint defects like blistering or orange peel. the interplay between the aluminum substrate's properties, the paint chemistry, and the curing parameters is vital for consistent product quality. Data analysis from our quality control checks, including adhesion tests and UV exposure studies, informs ongoing improvements to our painting process and allows us

The “H14” temper indicates the sheet has been strain-hardened and partially annealed. This temper provides medium strength with excellent formability and surface smoothness — essential for producing consistent, defect-free coatings in painted aluminium.

The Art and Science of Painted Aluminum Sheet 3105 H14

Why choose painted aluminum over bare aluminum or finished with other surface treatments?

Enhanced Protection and Longevity:Painting the 3105 H14 sheet introduces an extra shield against environmental wear—UV rays, moisture, and pollution. Unlike anodized finishes, painted surfaces can absorb or reflect sunlight, controlling temperature impacts on the material below.

Customizable Appearance:The pigmented coating allows for a wide color palette deployment, consistent texture, and finish specification—from matte to glossy. It becomes an architectural asset for creative technicians to realize stunning façades or interiors without compromising performance.

Maintenance Friendly:Painted aluminum keeps structures visually fresh, resists fungi or algae outbreaks, and reduces dirt accumulation. Routine washing eases cleaning, cutting down costs long term.

Lightweight and Robust:Known for its lightweight but good mechanical properties relative to steel, 3105 H14 painted sheets artfully balance transportation and installation efficiency without weakness at stresses.

Technical Parameters and Features

| Parameter | Typical Value |

|---|---|

| Alloy | 3105 |

| Temper | H14 (strain-hardened + recovery anneal) |

| Thickness Range | 0.4 mm to 2.0 mm |

| Width | Standard sheets up to 1500 mm |

| Length | Custom cut available |

| Yield Strength | Approx. 140 - 190 MPa |

| Ultimate Tensile Strength | Approx. 210 - 260 MPa |

| Elongation at Break | 6 - 10% |

| Surface Treatment | Polyester or PVDF based finish |

| Paint Thickness (dry film) | 20 - 30 microns |

| Coating Adherence | Excellent adhesion per ASTM D3359 |

| Corrosion Resistance | Superior in marine and industrial zones |

Chemical Composition

| Element | Percentage (%) Range |

|---|---|

| Aluminum (Al) | Balance (≥ 97.0%) |

| Manganese (Mn) | 0.5 - 1.0 |

| Magnesium (Mg) | 0.1 - 0.5 |

| Silicon (Si) | ≤ 0.3 |

| Iron (Fe) | ≤ 0.7 |

| Copper (Cu) | ≤ 0.1 |

| Zinc (Zn) | ≤ 0.1 |

| Titanium (Ti) | ≤ 0.03 |

Implementation Standards

To ensure performance consistency and reliability, Painted Aluminum Sheets 3105 H14 comply with notable industry standards, such as:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate.

- EN 485-2: Aluminum and aluminum alloys—Sheet, strip and plate—Part 2: Mechanical properties.

- AAMA 2605-13: High-performance organic coatings for architectural aluminum.

Meeting these international standards promises users mechanical integrity, surface quality, and chemical resistance expected for high-stature jobs in residential, commercial, and industrial sectors alike.

Application Insights

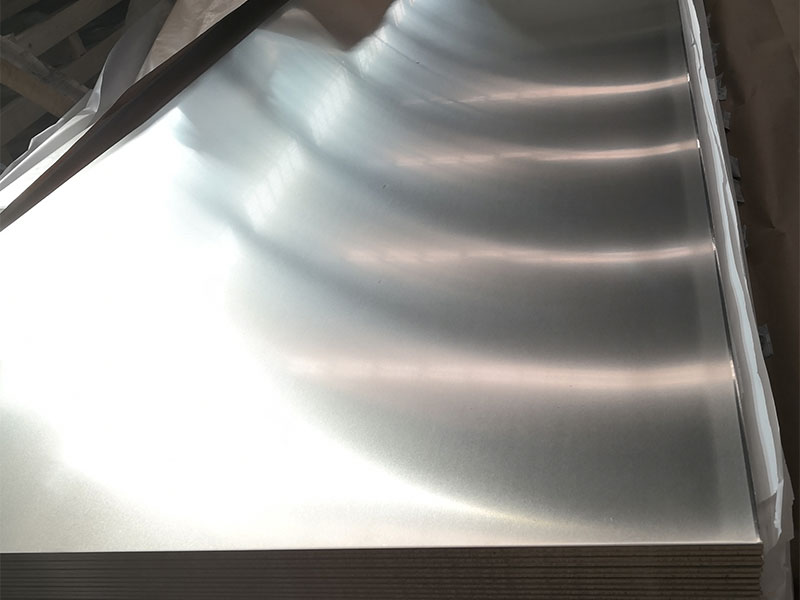

From sunscreen paneling, roofing sheets, signboards, to home interior decoration, these painted sheets offer versatility unhindered by environmental realities. The extra finish emphasizes ongoing durability, optimal UV shielding—critical for reducing thermal dilation when exposed outside—and magnificent curb appeal for prominent structures and innovative designs.

Additionally, 3105 alloy's compatibility with roll forming, cutting, bending, and welding techniques means fabricators can shape complex geometry without compromising layered coating adherence.

https://www.aluminumplate.net/a/painted-aluminum-sheet-3105-h14.html