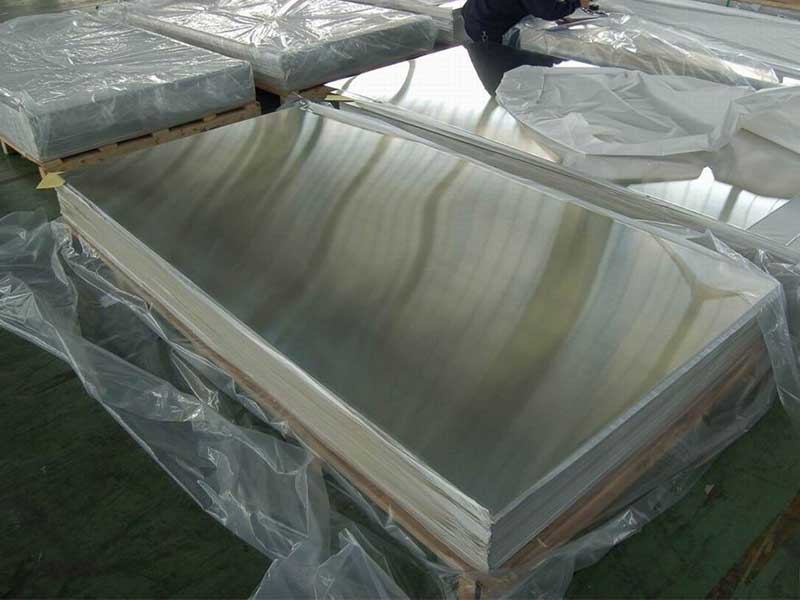

0.4 mm aluminium sheet

When you think of aluminum, your mind probably conjures images of bulky metal sheets or heavy-duty structures. But what if I told you that some of the most significant advancements in industries depend on the finely crafted, unexpectedly lightweight, and deftly versatile 0.4 mm aluminum sheets? This thin slice of aluminum has carved a niche for itself in various applications, marrying utility with innovation in ways that are both unique and practical.

The Allure of Slimness

At just 0.4 mm thick, these aluminum sheets embody the principle of 'less is more.' The slight thickness not only reduces the weight, which is crucial in applications where efficiency and portability matter, but it also allows for a more seamless integration into intricate designs. From the automotive industry to architecture and even packaging, this gauged aluminum finds its way into multifaceted applications, emerging as a silent enabler of modern engineering and design.

Chemical Properties and Composition

0.4 mm aluminum sheets fall under various alloy compositions, the most common being the 1050, 1100, 2024, and 6061 series. The specific elements in these alloys directly impact their chemical and physical properties. Here’s a concise table highlighting the composition and properties:

| Alloy Series | Primary Alloying Elements | Properties | Typical Applications |

|---|---|---|---|

| 1050 | 99.5% Aluminum | Excellent corrosion resistance, high thermal conductivity | Chemical and food processing |

| 1100 | 99.0% Aluminum | Ductile, great for forming, and weldability | Cooking utensils, heat exchangers |

| 2024 | Copper (Cu) 4.0% | High strength, good fatigue resistance | Aerospace structural components |

| 6061 | Silicon (Si) 0.4%, Magnesium (Mg) 0.8% | Strong, lightweight, good corrosion resistance | Structural applications, automotive parts |

Implementation Standards

To ensure the quality and safety of 0.4 mm aluminum sheets, they must adhere to certain industry standards. Two crucial standards are the American National Standards Institute (ANSI) and the Aluminum Association Standard 108 (AA).

- Manufacturing Standards: These involve specific guidelines for thickness tolerances that are crucial for maintaining even quality during mass production. For a 0.4 mm sheet, a typical tolerance might be ±0.05 mm.

- Mechanical Properties: Required tensile strengths may vary, but generally, 6061 aluminum has a minimum yield strength of 55 MPa while still affording malleability.

These implementation standards ensure that regardless of application, the aluminum sheet retains integrity and performance.

Tempering: The Strength Behind the Thinness

Tempering greatly influences the final performance characteristics of a 0.4 mm aluminum sheet. Common tempering processes include T3, T4, and T6, each specifically designed to optimize strength and malleability through thermal treatments.

- T3: Cold worked and solution heat-treated for strength and moderate workability.

- T4: Solution heat-treated, then naturally aged to improve ductility and formability.

- T6: Solution heat-treated and artificially aged to achieve maximum strength.

Choosing the correct temper can be integral to the fabricator’s success, ensuring that the resulting structures can withstand both physical loads and environmental stresses.

Applications Abound

One of the most striking characteristics of 0.4 mm aluminum sheets is their applicability across countless domains:

- Automotive Components: Lightweight yet strong panels contribute to fuel efficiency while maintaining structural integrity.

- Electronics: High-performance devices benefit from the heat dissipation properties enabled by using 0.4 mm aluminum sheets as casings.

- Architecture: Sleek facades crafted from this gauge produce a modern aesthetic without compromising on safety or durability.

- Food and Beverage Packaging: Their corrosion resistance combined with lightweight properties offers innovative packaging options that maintain product integrity.

Closing Thoughts

Whether embracing a cutting-edge, minimalist architectural concept or engineering the next breakthrough in automotive design, a 0.4 mm aluminum sheet is more than a mere tool; it is a canvas upon which creativity meets functionality. This unassuming material plays an underestimated yet critical role in enhancing our lives and shaping our future, reinforcing the notion that even the thinnest lines can lead to substantial outcomes. Metal may be cold and hard, but within its layers lies the warmth of human ingenuity waiting to be unveiled.