Aluminium Sheet Plate For Ship

The significance of aluminium sheet plates in the shipbuilding industry cannot be overstated. With its unique blend of strength, durability, and lightweight properties, aluminium has become a preferred choice for modern marine construction.

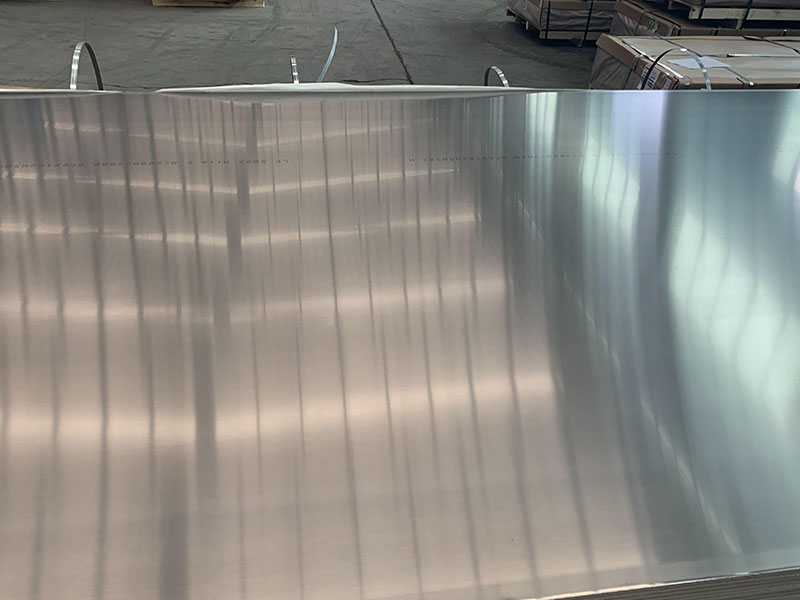

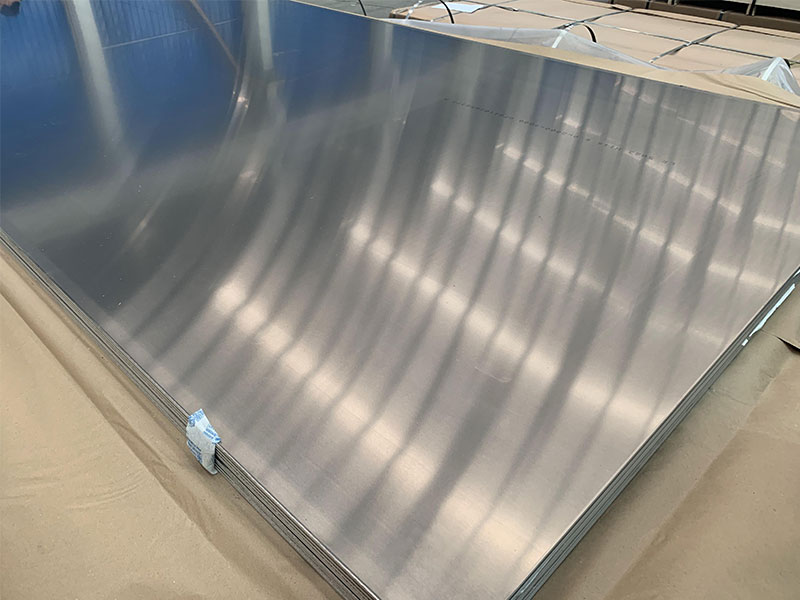

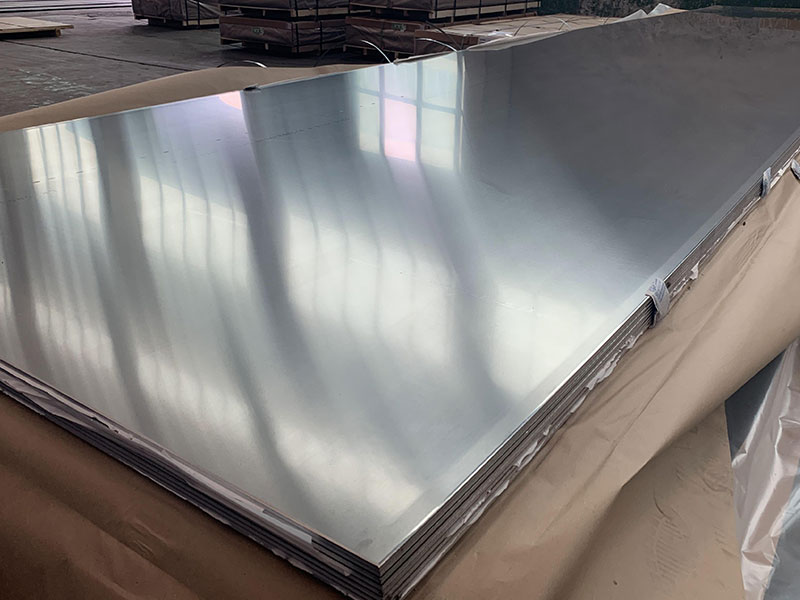

Aluminium Sheet Plates

Aluminium sheet plates are flat pieces of aluminium that vary in thickness and are processed for a multitude of engineering applications, including shipbuilding. Their lightweight nature significantly enhances fuel efficiency and speed, resulting in cost-effective maritime solutions. How do these attributes not only propel advancements in naval architecture but also establish environmental sustainability in shipbuilding?

Parameters to Consider

When discussing aluminium sheet plates for marine applications, certain parameters are crucial in determining their suitability:

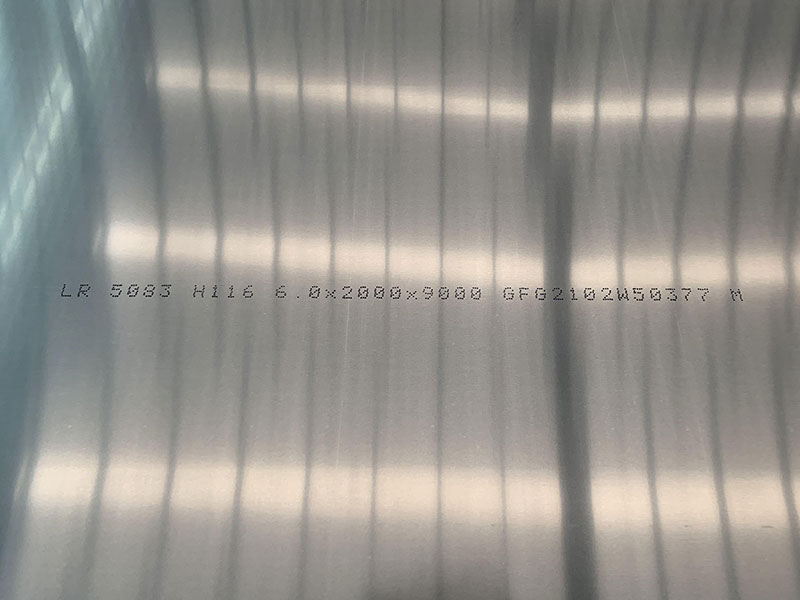

- Thickness: Typically ranges from 1mm to 300mm, depending on the structural requirements.

- Width/Length: Standard sizes usually exceed 2000mm in width and 6000m in length, allowing for expansive designs.

- Density: Generally, aluminium boasts a density of about 2.7 g/cm³, enabling reduced deadweight.

- Performance Metrics: The mechanical properties should comply with the Maritime industry standards, particularly the yield strength and tensile strength, often being significantly higher than traditional materials used in shipbuilding.

Implementation Standards: The Backbone of Reliability

Implementing aluminium sheet plates require strict adherence to international and regional standards. This authentication guarantees that the produced aluminium conforms to specific criteria for performance:

- ISO 5730: Specifications for coated aluminium and its quality.

- EN or ASTM Standards: For mechanical performance and corrosion resistance.

- DNV GL Rules or BV Rules: Specific guidelines for shipclassification.

Apart from meeting general framework strengths, attention must be placed on marine environmental effects - including factors such as seawater corrosiveness, resulting in advanced requirements for aluminium coatings for marine applications.

Alloy Tempering: Enhancing Material Characteristics

Globally, aluminium come in various alloys; each specific receipt possesses varying qualities. The tempering process significantly alters these alloys’ attributes to adapt them for optimal ship functions. Here's a look at common aluminium alloy grades applied in maritime contexts:

| Alloy | Composition | Tempers | Properties |

|---|---|---|---|

| 5083 | Al, Mg, Mn, Cr | H111, H112 | Excellent corrosion resistance |

| 6061 | Al, Mg, Si | T4, T6 | Good wear resistance and machinability |

| 4655 | Al, Cu, Fe, Mg | H321 | High strength to weight ratio |

| 3003 | Al, Mn | H14, H16 | Excellent weldability, formability |

Within these alloys, the H temper typically denotes a heat-treated state which increases the strength without compromising on ductility, essential features for the stress encountered during maritime operations.

Chemical Properties: The Foundation of Longevity

Aluminium's resistance to corrosion is primarily a result of its smart oxide formation; these properties fundamentally mitigate long-term degradation stemming from exposure to harsh marine environments. The favourable chemical properties include:

- Corrosion Resistance: An inherent bond creates a protective oxide layer in relative seawater environments.

- Scalability of Potential Barrier Coatings: Some of these can enhance resistance even further—coatings are epoxy impairments and silicate paints specifically analyzed under brutal maritime weather terrors.

https://www.aluminumplate.net/a/aluminium-sheet-plate-for-ship.html