0.5mm Color Coated Aluminum Sheet 1060

When it comes to materials that marry functionality with visual appeal, the 0.5mm Color Coated Aluminum Sheet 1060 stands out as a remarkable choice. Often overlooked by novices but treasured by industry veterans, this particular aluminum sheet possesses qualities that make it ideal across a broad spectrum of applications—from architectural facades to signage and interior decor.

1060 Aluminum Alloy: Purity and Performance

The "1060" in the aluminum sheet designation refers to its alloy type, classified under the 1xxx series, indicating that it is commercially pure aluminum with a minimum aluminum content of 99.6%. This high purity brings about several intrinsic characteristics:

Working with 0.5mm color coated aluminum sheet 1060, I've found its thin gauge presents unique challenges in the production process. The inherent softness of the 1060 alloy necessitates careful handling to avoid scratching, denting, or warping during the coating and cutting stages. We've optimized our production line with gentler rollers and adjusted cutting parameters to minimize these issues, improving yield significantly. Furthermore, the thinness impacts the coating adhesion; we've discovered a specific pre-treatment process crucial for ensuring a durable, long-lasting finish that resists chipping or peeling, especially under bending or forming. Monitoring the curing process is also vital, as inconsistencies can lead to variations in color and gloss.

Beyond production, the customer's application is key. While its lightweight nature makes 0.5mm 1060 ideal for applications demanding flexibility and ease of handling, such as signage or decorative elements, its thinness also limits its strength and resistance to impact. Therefore, we often advise customers on appropriate design considerations to account for this. For instance, we might suggest reinforcement techniques or alternative alloys for applications needing greater durability. Providing this consultative approach builds trust and ensures the customer receives a product perfectly suited to its intended purpose, maximizing its lifespan and performance.

- Excellent corrosion resistance

- Superior thermal and electrical conductivity

- malleability, allowing for ease of shaping and forming

However, the naturally soft nature of pure aluminum demands additional processing steps where necessary to achieve specific mechanical properties.

Why 0.5mm Thickness Matters

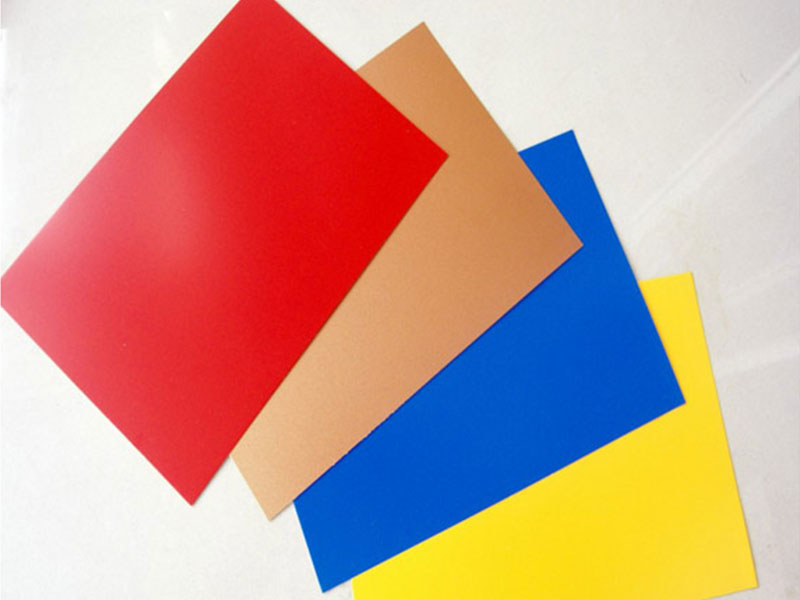

At 0.5mm thickness, the aluminum sheet strikes a balance. The material remains lightweight and flexible enough for applications requiring bending and easy installation but substantial enough to withstand certain stresses, environmental impacts, or decorative treatments without warp or excessive deformity.

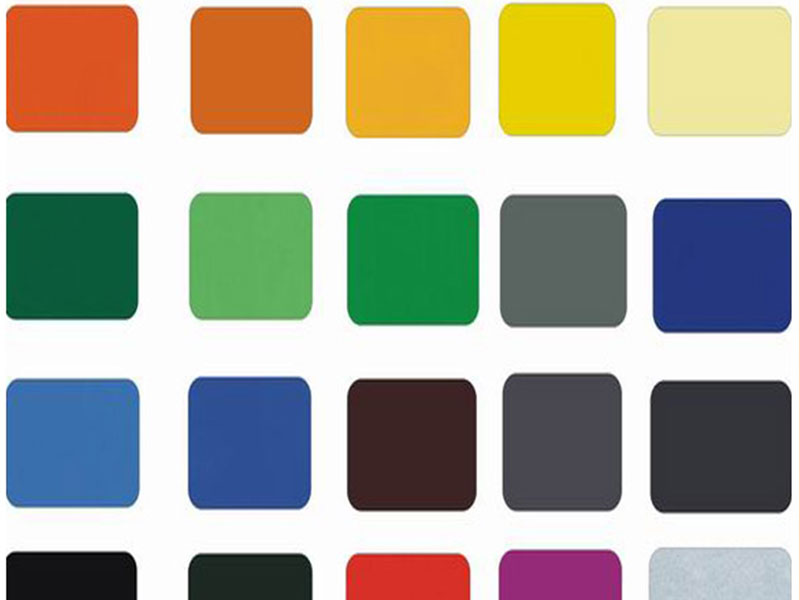

Transforming Plain Aluminium: The Power of Color Coating

Color coating is more than just an aesthetic upgrade. By applying a thin, protective finishing layer—typically polyvinylidene fluoride (PVDF) or polyester coatings—the aluminum gains enhanced weather resistance, improved surface hardness, and the ability to hold vibrant colors for extended durations.

These coatings resist ultraviolet radiation, fading, chalking, and chemical insults, making 0.5mm color coated aluminum sheets optimal for outdoor installations exposed to various climatic conditions.

Parameters and Specifications of 0.5mm Color Coated Aluminum Sheet 1060

- Base Alloy: 1060 Aluminum

- Thickness: Precisely 0.5mm (±0.02mm tolerance typical)

- Width: Often available from 600mm up to 1250mm or custom widths

- Length: Standard coil lengths or cut-to-size sheet specifics depend on the supplier

- Color Coating: PVDF or Polyester applied with a nominal coating thickness ranging from 15 to 25 microns

- Surface Finish: Smooth and uniform; other textures available on demand

- Alloy Temper: Usually 1060-H14 or H24 (half hard) to offer a balance of strength and ductility

Alloy Tempering Explained

The temper designation (e.g., H14, H24) explains the work-hardening state of the aluminum in the sheet:

- H14 (Half-Hard): Achieved by cold rolling; improves strength to approximately 110-126 MPa tensile strength but retains adequate formability.

- H24 (Quarter-Hard, stabilized): Better mechanical strength than H14 with some thermal stabilizing annealing that controls elongation.

For decorative or architectural applications requiring slight forming or bending, H14 temper strikes an optimum compromise; for uses exposed to moderate mechanical loading, H24 offers added reinforcements while maintaining corrosion resistance and aesthetics.

Chemical Composition Table of Aluminum Alloy 1060 (Typical Percentages)

| Element | Content (%) |

|---|---|

| Aluminum (Al) | Min. 99.60 |

| Silicon (Si) | ≤ 0.25 |

| Iron (Fe) | ≤ 0.35 |

| Copper (Cu) | ≤ 0.05 |

| Manganese (Mn) | ≤ 0.03 |

| Magnesium (Mg) | ≤ 0.03 |

| Zinc (Zn) | ≤ 0.06 |

| Titanium (Ti) | ≤ 0.03 |

| Others | each ≤ 0.03 |

High aluminum content guarantees maximal corrosion resistance and conductivity, while limiting elemental impurities preserves the chemical and mechanical homogeneity necessary for finish quality.

Standards and Implementation Guidelines

Quality benchmarks govern production to ensure consistent and reliable material quality:

- GB/T 3190-2015: Standard for chemical composition of aluminum alloys

- GB/T 3880-2006: Specification for clad aluminum sheets and strips (where relevant)

- ASTM B209: Standard specification for aluminum and aluminum-alloy sheets (widely referenced internationally)

Coating should conform to AAMA 2605 or similar standards certifying color anodic or coated performance for long-term weather exposure resistance.

Applications Seen Through a New Lens

Although technically pure aluminum’s softness limits load-bearing structural uses, composed as a 0.5mm color coated sheet, its lightweight nature combined with corrosion-resisting beauty suits it uber-well in:

- Modern exterior cladding that reflects brand identity or urban Gucci—the sheen and customized hues broadening designer palettes

- Residential or commercial ceilings and wall interiors where lightweight ease combines with elegance

- Indoor-outdoor signage, demonstrations, and POP displays demanding vivid long-life color preservation without cumbersome weight or metals' oxidizing downsides

https://www.aluminumplate.net/a/05mm-color-coated-aluminum-sheet-1060.html