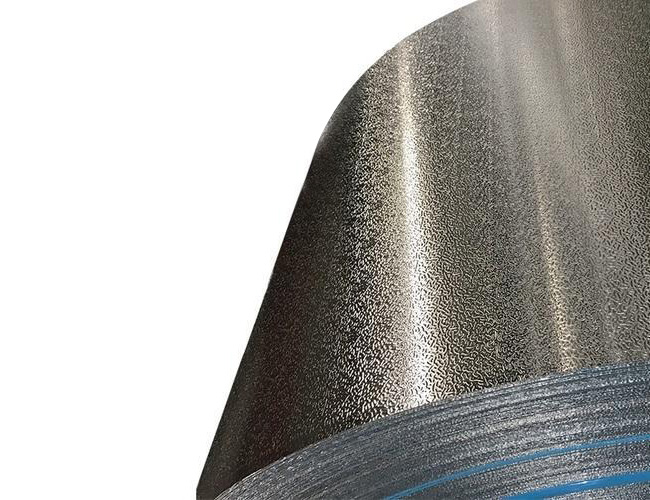

Embossed tin aluminum sheets

Embossed tin aluminum sheets are specialized aluminum products featuring a raised or patterned surface texture achieved through an embossing process. These sheets combine the advantageous properties of both aluminum and tin coatings to excel in aesthetics, corrosion resistance, mechanical performance, and usability.

What Are Embossed Tin Aluminum Sheets?

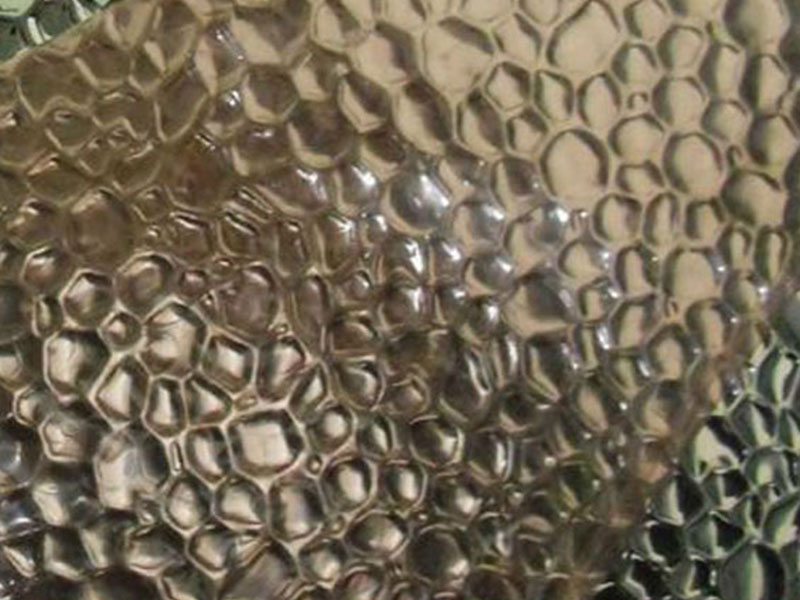

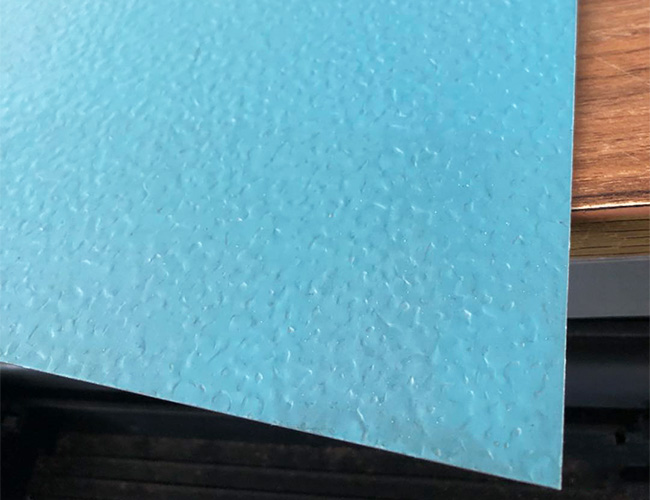

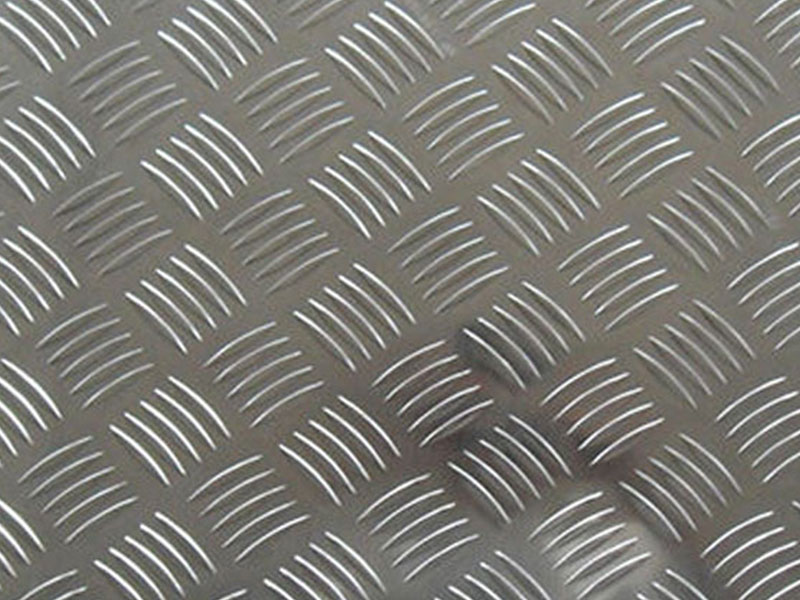

An embossed tin aluminum sheet is a flat or rolled aluminum alloy sheet coated with a thin layer of tin or tin alloy and then embossed to create decorative and functional surface textures. The embossing surface ranges from simple geometric patterns to digitally designed textures, enhancing appearance and improving grip, stiffness, or other mechanical aspects related to surface area.

The tin layer significantly improves corrosion resistance by protecting the aluminum substrate from environmental factors, making these sheets ideal for use in challenging industrial and consumer applications.

Features

| Feature | Description |

|---|---|

| Material Base | Aluminum Alloy (typically 1050, 1100, or 3003 series) |

| Coating | Pure Tin or Tin Alloy coating providing exceptional corrosion resistance |

| Embossing Pattern | Available in various patterns: diamond, ripple, linen, hexagonal, or customized designs |

| Thickness Range | Generally 0.15 mm to 0.8 mm, depending on application |

| Surface Finish | Embossed, non-slip, decorative, environmentally stable |

| Weight | Lightweight compared to other metals with similar properties |

| Corrosion Resistance | Excellent, particularly suitable for food and chemical-safe environments |

| Mechanical Strength | Increased stiffness due to embossing combined with aluminum’s natural ductility |

| Thermal & Electrical Conductivity | Moderate, dependent on aluminum alloy & embossing depth |

Chemical Composition

The base aluminum alloys commonly used for embossed tin aluminum sheets have the following general chemical composition:

| Element | Typical Range (%) | Notes |

|---|---|---|

| Aluminum (Al) | 97.0 - 99.5 | Principal metal, remainder balance |

| Silicon (Si) | 0.25 max | Improves strength & corrosion resistance |

| Iron (Fe) | 0.4 max | Traces permissible depending on alloy |

| Copper (Cu) | 0.05 - 0.2 | Enhances mechanical strength |

| Manganese (Mn) | 0.3 - 1.0 | Increases strength & hardness |

| Zinc (Zn) | 0.1 max | Mostly minimal for this product |

| Tin (Sn) | 99.8 (coating) | Tin applied as surface coating |

Note: The tin is present as a coating layer, typically 2-15 microns thick.

Technical Specifications

| Parameter | Typical Values | Unit |

|---|---|---|

| Sheet Thickness | 0.15 - 0.8 | mm |

| Embossing Depth | 0.03 - 0.25 | mm |

| Surface Hardness (Tin Layer) | 20 - 60 (Vickers Hardness HV) | HV |

| Tensile Strength | 90 - 150 | MPa |

| Yield Strength | 40 - 110 | MPa |

| Elongation | 10 - 35 | % |

| Density | 2.7 | g/cm³ |

| Thermal Conductivity | 205 | W/m·K |

| Electrical Conductivity | 34.5 | MS/m |

| Corrosion Resistance Rating | Excellent | N/A |

| Tin Coating Thickness | 2 - 15 | microns |

| Maximum Operating Temperature | 200 | °C |

| Aluminum Grade | 1050-H14, 1100-O, 3003-H12 | Standard Designation |

Performance Benefits

- Corrosion Protection: Tin layers provide excellent anticorrosive properties, particularly ideal for acidic or salty environments.

- Enhanced Mechanical Properties: Embossing adds rigidity without increasing thickness or weight, providing improved performance in structural applications.

- Aesthetic Enhancement: Embossed surfaces offer visual appeal for architectural and decorative use.

- Food Safety Compliance: Tin coating is FDA-approved for direct contact with various foodstuffs, ideal for packaging.

- Non-slip Surface: Embossed pattern enhances grip properties — critical in handling or safety equipment.

- Lightweight Strength: Retains aluminum's excellent strength-to-weight ratio for cost-effective and high-performance outcomes.

- Thermal Conductivity: Makes it suitable for mild heat exchange environments depending on design.

Applications and Use Cases

| Industry | Typical Application Areas | Benefits in Application |

|---|---|---|

| Food Packaging | Cans, trays, lids, foil packaging | Corrosion resistant, FDA-approved, lightweight |

| Electrical Enclosures | Panel coverings, housing for electrical components | Anticorrosion, heat dissipation, lightweight |

| Architecture | Decorative paneling, ceiling sheets, surface decorations | Aesthetic embossing, durability |

| Automotive | Interior trim, lighter chassis components | Weight-saving, stiffness, corrosion protection |

| Consumer Products | Appliance panels, household tools | Non-slip embossing, easy cleaning, durability |

| Chemical Industry | Containers, protective layer for aggressive environments | Corrosion protection under chemical exposures |

Handling & Installation Recommendations

- Ensure handling with soft cloth gloves to avoid scratches on embossed tin surfaces.

- Recommended storage indoors under dry conditions to maximize corrosion protection.

- Avoid abrasive cleaning agents; use mild detergents or solvents.

- Cutting and fabrication should maintain edge integrity due to thin tin layers.

- When used for food-grade applications, follow sanitation requirements meticulously.

https://www.aluminumplate.net/a/embossed-tin-aluminum-sheets.html