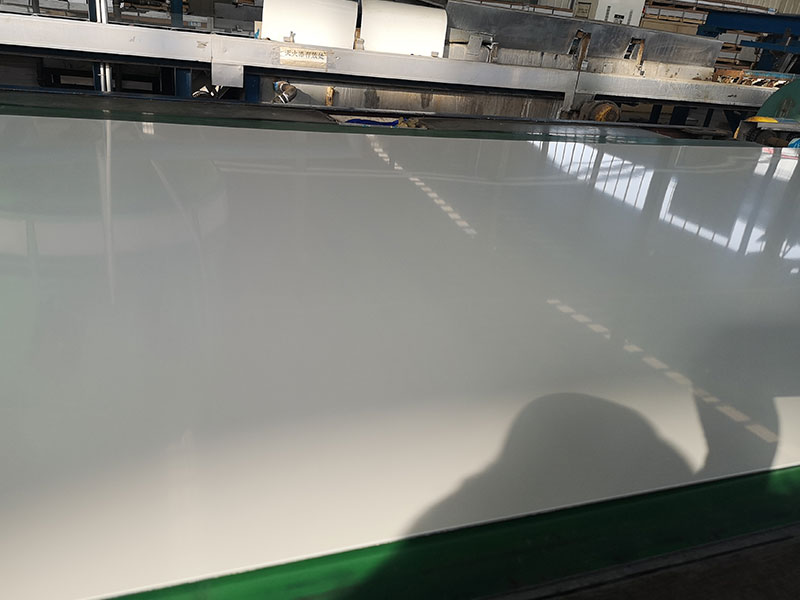

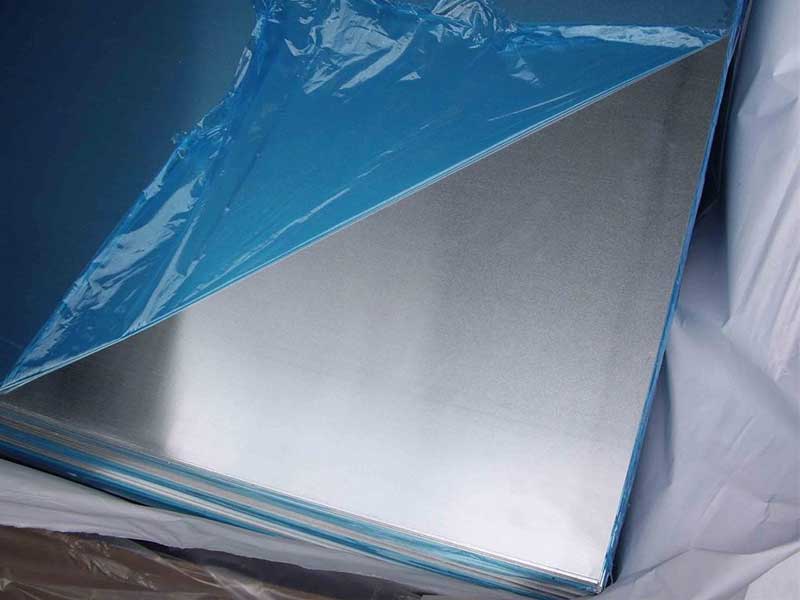

3003 h24 aluminum sheet

Walk into a commercial kitchen, open an air conditioner, or climb a building wrapped in bright, clean cladding, and you are very likely looking at 3003 H24 aluminum sheet without even knowing it. It is not the show-off of the alloy world. It is not the aerospace-grade celebrity or the ultra-hard armor plate. Instead, 3003 H24 is the quiet workhorse: unpretentious, reliable, and precisely engineered for the jobs most metals find annoying.

To understand why this alloy-temper combination has become a global staple, it helps to look at it from an unusual angle: less as a piece of metal and more as a carefully balanced compromise between physics, chemistry, manufacturing realities, and long-term durability.

What “3003 H24” Really Means

Behind that short designation is a story of composition and controlled deformation.

The “3003” tells you which family it belongs to. It is an aluminum–manganese alloy, non-heat-treatable, designed to gain its strength from cold work rather than high-temperature heat treatment. The addition of manganese, along with small amounts of other elements, stabilizes the structure and improves strength and corrosion resistance beyond what pure aluminum can offer.

The “H24” is where the personality of the sheet emerges. H24 means the material was strain hardened to a certain level (the “H2” path) and then partially annealed (“4” indicates a half-hard temper). In simple terms, the sheet has been cold-rolled to increase its strength, then gently relaxed so it does not become too brittle. The result: a pleasant middle ground between softness and strength, between formability and durability.

The Chemist’s View: A Deliberate Recipe

From a chemical standpoint, 3003 is not flashy, but it is deliberate. A typical composition range follows these guidelines:

| Element | Typical Content (wt%) |

|---|---|

| Aluminum (Al) | Balance (≈ 96.8–99.0) |

| Manganese (Mn) | 1.0–1.5 |

| Copper (Cu) | 0.05–0.20 |

| Silicon (Si) | ≤ 0.6 |

| Iron (Fe) | ≤ 0.7 |

| Zinc (Zn) | ≤ 0.1 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

Manganese is the main supporting actor. It refines the grain structure, boosts strength, and enhances resistance to certain forms of corrosion. The tiny amount of copper improves strength slightly but is kept low to avoid sacrificing corrosion resistance.

Because 3003 is a non-heat-treatable alloy, the chemistry is tuned so that the properties respond predictably to rolling and annealing rather than to solution heat treatment and quenching. That predictability is a large part of its industrial appeal.

The Engineer’s View: Mechanical Balance Over Extremes

From a mechanical perspective, 3003 H24 stands right in the middle of the spectrum: stronger than very soft, fully annealed 3003-O, but still comfortably formable compared with harder tempers like H26 or H28.

Typical room-temperature mechanical properties for 3003 H24 sheet (values vary with thickness and standard):

| Property | Typical Value |

|---|---|

| Tensile strength | ≈ 145–180 MPa |

| Yield strength (0.2% offset) | ≈ 115–150 MPa |

| Elongation (thickness-dependent) | ≈ 5–12% |

| Brinell hardness (HBW) | ≈ 40–55 |

In practical terms, this means:

- Enough strength to withstand handling, forming, and service loads in ductwork, covers, and panels.

- Enough elongation to manage bending, shallow drawing, and moderate forming without tearing, as long as bending radii and processing conditions are sensible.

- Hardness adequate to resist casual dents and scratches better than dead-soft tempers, but not so high that springback becomes unmanageable in press brakes.

If you are a designer, 3003 H24 feels like choosing a sensible, middle-weight structural profile instead of an exotic composite: it simply behaves as expected.

The Production View: A Sheet That Cooperates

On the factory floor, an alloy encounters rolling mills, shears, punches, forming presses, and welders. This is where the “temper” becomes as important as the alloy itself.

For 3003 H24:

- Roll forming and bending respond well when minimum inside bend radii are respected. For many thicknesses, a bend radius of at least 1–1.5 times the sheet thickness is a safe starting point, adjusted according to direction relative to the rolling grain.

- Deep drawing is better handled by softer tempers like H14 or O, but H24 can still be used for shallow, well-controlled operations.

- Punching and shearing give clean edges with minimal burr when dies are sharp and clearances are correct, taking advantage of the alloy’s moderate strength and ductility.

Because 3003 is non-heat-treatable, its properties are not significantly enhanced by post-forming thermal cycles. It is designed to be formed in its final temper. That’s a major difference from alloys like 6061-T6, where complex parts might need to be formed in a softer temper and then heat treated to regain strength.

The Corrosion Story: Long-Term Calm in Harsh Surroundings

One of the quiet triumphs of 3003 H24 is its corrosion behavior. Thanks to aluminum’s natural oxide film and the stabilizing effect of manganese, the sheet performs well in:

- Mildly corrosive industrial atmospheres

- Food and beverage environments (non-contact surfaces or with proper surface conditioning and approvals)

- HVAC systems and building façades exposed to normal urban conditions

Chloride-rich or highly alkaline environments always demand extra consideration, but, in many everyday applications, 3003 H24 can be used uncoated. When appearance matters, anodizing or painting can be added. It will not anodize to the brilliant clarity of some 5xxx or 6xxx alloys, but it still takes a decent protective and decorative finish.

Standards, Temper Control, and Consistency

In real-world procurement, the name “3003 H24” is only the starting point. Conformance to recognized standards is what ensures the sheet you receive behaves like the datasheet you designed around.

Common standards and references include:

- ASTM B209 for aluminum and aluminum-alloy sheet and plate

- EN 573 (chemical composition) and EN 485 (mechanical properties and tolerances) for European markets

- JIS H4000-based specifications in some Asian markets

Within these frameworks, H24 is defined by:

- A controlled range of strain hardening

- A specific level of partial annealing that sets hardness and mechanical properties

- Tight tolerances on thickness, flatness, and edge conditions

Reputable producers track rolling reductions, annealing temperatures, and cooling rates with precision. This consistency is crucial, especially if your process is sensitive to springback, bending performance, or welding quality.

Joining and Surface Treatment: Playing Well with Others

A 3003 H24 sheet is rarely used in isolation. It is riveted to frames, welded into ductwork, or adhesive-bonded to insulation layers. Its behavior in these joining methods adds to its reputation as a cooperative material.

- Welding: 3003 is readily weldable by common processes such as TIG and MIG, typically using 1100, 4043, or compatible filler wires depending on the design. Because it is strain-hardened, some loss of strength occurs in the heat-affected zone, so weld layout and joint design should account for this.

- Brazing and soldering: With proper fluxes and procedures, brazing is feasible, particularly in controlled factory environments like heat-exchanger production.

- Adhesive bonding: The naturally clean, oxide-covered surface bonds well when properly degreased and pretreated.

Surface finishes range from mill finish and stucco embossing to painted coils for building cladding. The H24 temper helps maintain panel flatness and reduces “oil canning,” particularly when sheets are assembled into large visual surfaces.

Where 3003 H24 Quietly Dominates

Look behind the scenes, and you find 3003 H24 in places where the metal must be formed, must not rust away rapidly, and must stay cost-effective:

- HVAC ducting and housings

- Cooking utensils, kitchen equipment housings, and non-contact panels for food processing

- Insulation jacketing for pipelines and tanks

- Building façade panels, soffits, and interior decorative panels

- Light-duty chemical equipment and containers for non-aggressive media

- Reflectors, signage backplates, and protective covers

In many such applications, a stronger alloy is not necessary, and a softer one would deform too easily. The H24 temper provides that “just right” combination that keeps installations dimensionally stable without complicating fabrication.

Choosing 3003 H24 Intelligently

Selecting 3003 H24 is not just a default decision; it is a strategic choice when:

- Corrosion resistance and appearance are more important than ultimate strength.

- Forming operations are moderate, not extreme, and must be done in a single temper.

- Cost and availability take priority over specialized aerospace or marine-grade alloys.

- Long-term stability in indoor or mildly outdoor environments is required without complex protection systems.

Seen from this angle, 3003 H24 becomes less of an anonymous catalog item and more of a well-tuned engineering compromise: chemistry designed for cold work, temper designed for balanced performance, and standards designed for reproducibility.

It will never be the star of a marketing brochure, but it will quietly hold together the ducts, panels, jackets, and enclosures that modern buildings, factories, and kitchens rely on every day. In a world full of exotic materials, there is a certain elegance in a metal that simply does its job, decade after decade, with almost no one noticing.

https://www.aluminumplate.net/a/3003-h24-aluminum-sheet.html