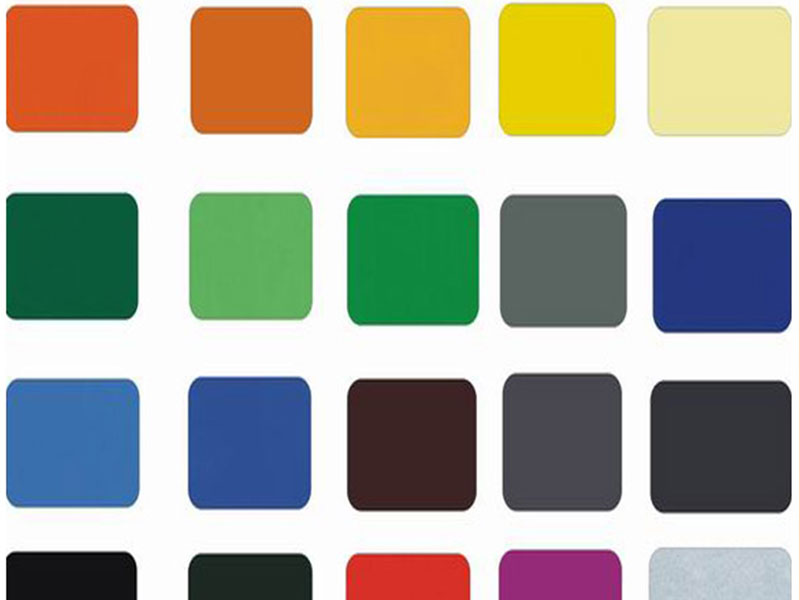

Colors anodized aluminium sheet

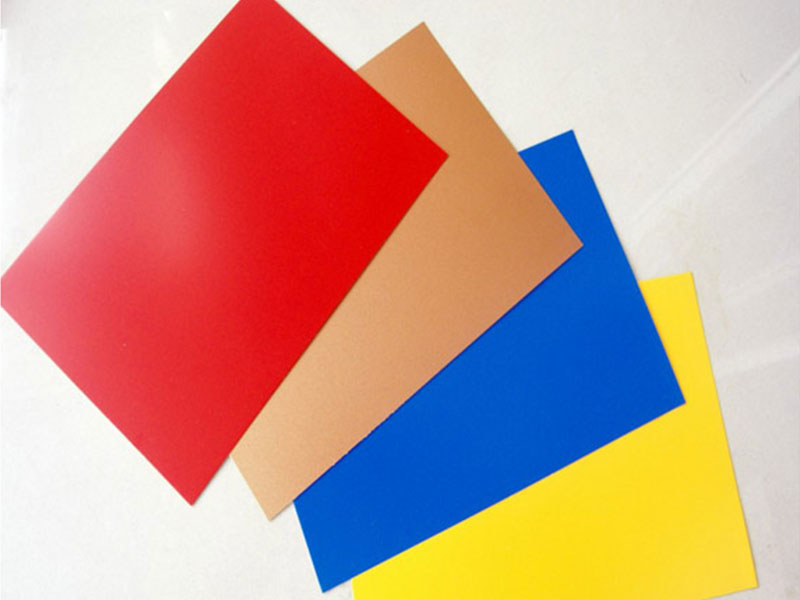

Color anodized aluminium sheet looks simple on the surface: just a piece of metal with a beautiful colored finish. But behind that smooth panel is a carefully engineered system of alloy design, surface chemistry, and controlled electricity. how those elements work together helps you choose the right sheet for both appearance and performance—and explains why not all colored anodized panels are equal.

What is color anodized aluminium sheet?

Anodizing is an electrochemical process that grows a controlled oxide layer on aluminium. Unlike paint or organic coatings that sit on top of the metal, anodizing converts the outer aluminium surface itself into aluminium oxide. That oxide is:

- Harder than the underlying aluminium

- Chemically stable

- Naturally porous at a microscopic level

Color anodized aluminium sheet takes advantage of those pores. After anodizing, dyes or inorganic pigments are absorbed into the oxide layer and then sealed. The result is a colored surface that is:

- Integral to the metal

- Highly resistant to UV, scratching, and corrosion

- Uniform and metallic in appearance, not plastic-like

This makes color anodized sheet a preferred choice for architectural façades, interior decoration, signage, consumer electronics, kitchen and bathroom panels, and transport interiors where durability and visual quality both matter.

Most people think of color purely as decoration; in anodized aluminium, color is actually a side effect of controlling oxide microstructure.

- Layer thickness determines depth and saturation of color

- Pore size and distribution influence how dyes penetrate and how light reflects

- Sealing chemistry changes gloss level and stain resistance

A black anodized panel for a high-end speaker grill and a champagne panel for an elevator cabin are both based on the same physical principle: the way light interacts with a transparent or semi-transparent oxide layer that contains colorants. Seen from this angle, choosing a color is also choosing a specific oxide architecture.

Typical alloys and tempers for anodizing

Not every aluminium alloy responds well to decorative anodizing. The chemistry of the base metal shapes the final color, consistency, and corrosion resistance.

Common alloys for color anodized aluminium sheet include:

1050 / 1100:

High-purity aluminium, excellent anodizing response, bright natural silver, good for decorative interior panels where formability is essential.3003 / 3004:

Manganese alloyed aluminium, slightly higher strength, good color uniformity, used in architectural panels and interior cladding.5005:

Magnesium alloyed aluminium, specifically developed for architectural anodizing. Offers very uniform color across large façades and is often the preferred choice for exterior applications.5052:

Higher strength magnesium alloy. Takes a good anodized finish, widely used when sheet must be formed or bent while still maintaining a high-quality appearance, such as vehicle interiors and marine trim.6061 (in sheet/plate):

Structural alloy. Anodizes well but color uniformity can vary more than in 5005; often used where strength takes priority over purely decorative uniformity.

Typical tempers used:

H14 / H24:

Half-hard tempers, balancing strength with good bendability for façade cassettes, profiles, and cladding.H16 / H18:

Harder tempers for parts that need resistance to denting and handling damage.O (annealed):

Very soft, used where deep drawing or complex forming comes first, and highest mechanical strength is not the priority.T6 (for 6xxx series):

Solution heat-treated and artificially aged. Good choice for structural panels that will still be visible elements.

The trick is matching alloy and temper to the application: large architectural surfaces favor 5005 H14 for uniform color, while small, machined decorative components might use 6061 T6 for precision and strength.

Process parameters that shape the final sheet

Color anodized aluminium sheet is the product of tightly controlled variables along the process chain. Some critical factors:

Pre-treatment

Mechanical brushing, polishing, or blasting sets the texture. Chemical etching and desmutting remove surface impurities. This step defines whether the final look is matte, satin, brushed, or mirror-like.Anodizing bath conditions

Electrolyte: usually sulfuric acid

Temperature: typically 18–22 °C for decorative anodizing

Current density and voltage: tuned to grow a specific oxide thicknessThinner layers (around 5–10 μm) give light, economical finishes suitable for interior use. Thicker layers (15–25 μm or more) increase wear and corrosion resistance for exterior or high-traffic applications.

Coloring

Organic dyes: wide color palette—red, blue, green, gold, bronze, black, etc. Excellent for decorative use, strong saturation.

Inorganic / electrolytic coloring: tin or other metal salts deposited in the pores, producing stable bronze to black shades with exceptional UV resistance, ideal for façades.Sealing

Hot deionized water, nickel acetate, or other sealing chemistries hydrate and close the pores. This final step locks in the color and dramatically improves corrosion resistance and stain resistance.

Each parameter can be adjusted; together they build a specific specification for a color anodized sheet optimized for a particular role.

Implementation standards and quality references

To ensure color, thickness, and durability are consistent, production and inspection refer to international and regional standards, such as:

- ISO 7599 – Anodizing of aluminium and its alloys – General specifications for anodic oxidation coatings on aluminium

- ISO 2360 – Measurement of coating thickness (eddy current method)

- EN 13523 (for some coil-coated references when combined processes are used)

- Qualanod specifications – widely respected quality label for architectural anodizing, defining minimum thickness, sealing quality, and test methods

Common target values for architectural and decorative color anodized sheet include:

Anodic film thickness:

Interior use: about 8–12 μm

Exterior use: about 15–25 μmSealing quality:

Assessed by weight loss tests in acid or dye spot tests in accordance with ISO methods or Qualanod criteria.Color consistency:

Measured by spectrophotometer in CIELAB space, with ΔE thresholds agreed between supplier and customer to control batch-to-batch variation.

Typical technical parameters

Below is a generalized property table for a widely used architectural alloy such as 5005 in H14 temper with decorative color anodizing. Exact values vary by supplier and thickness but this gives a realistic range.

Mechanical and physical properties (base alloy, typical):

| Property | Typical Value (5005 H14) |

|---|---|

| Tensile strength Rm | 145–185 MPa |

| Yield strength Rp0.2 | 110–145 MPa |

| Elongation A50 | 5–12 % |

| Density | ~2.71 g/cm³ |

| Modulus of elasticity | ~70 GPa |

| Thermal conductivity | ~200 W/m·K |

| Coefficient of thermal expansion | ~23 × 10⁻⁶ /K |

| Electrical conductivity | ~30–35 % IACS |

Anodic coating parameters (decorative colored finish):

| Parameter | Typical Range |

|---|---|

| Oxide layer thickness | 8–25 μm (application-dependent) |

| Surface hardness (oxide layer) | ~300–500 HV |

| Gloss level | Matte to high gloss (by design) |

| Color type | Organic dye / electrolytic color |

| UV resistance | High, especially electrolytic |

| Corrosion resistance (neutral salt spray) | Often >1,000 h with no base metal attack, when properly specified |

Basic chemical composition (example: 5005 alloy):

| Element | Typical Content (wt%) |

|---|---|

| Al | Balance |

| Mg | 0.50–1.10 |

| Si | ≤ 0.30 |

| Fe | ≤ 0.70 |

| Mn | ≤ 0.20 |

| Cu | ≤ 0.20 |

| Cr | ≤ 0.10 |

| Zn | ≤ 0.25 |

| Others | ≤ 0.05 each, ≤ 0.15 total |

Low levels of copper and other reactive elements are important; they help produce a clear, uniform oxide layer that accepts color evenly, crucial for large sheets and repeated batches.

Where color anodized sheet excels

From a user’s point of view, the advantages show up as everyday benefits:

Color stability outdoors

The inorganic oxide shield and UV-tolerant colorants outlast most paints. Façades stay within tight color tolerances for many years.Metal look, not plastic

The finishing process preserves the metallic character. Brushed lines, reflective highlights, and subtle grain remain visible through the colored layer.High scratch and wear resistance

The surface hardness of the oxide helps resist keys, bags, and cleaning tools in crowded spaces like elevators, transport hubs, and public interiors.Environmentally friendly profile

The coating is inorganic, thin, and integral to aluminium. The sheet remains fully recyclable, with no thick organic paint layers to remove.

Choosing the right sheet for your project

When specifying color anodized aluminium sheet, it helps to define:

- Application location: interior or exterior, rural or coastal

- Desired appearance: color tone, gloss level, surface texture (brushed, matte, polished)

- Fabrication steps: bending, punching, laser cutting, deep drawing

- Service life expectations: years of UV exposure, cleaning cycles, risk of mechanical wear

With that information, the alloy, temper, oxide thickness, coloring system, and sealing method can be tuned so that the sheet is not just “the right color” on delivery, but still right after long-term use.

Behind each elegant colored panel is a carefully designed combination of metal structure and surface chemistry. that relationship turns a simple color choice into a precise material specification—and ensures your anodized aluminium sheet performs as well as it looks.

https://www.aluminumplate.net/a/colors-anodized-aluminium-sheet.html