5052 mirror aluminum coil

The 5052 mirror aluminum coil is a specialized aluminum alloy coil, meticulously polished to exhibit a high-gloss reflective finish, akin to a mirror surface. This product combines the mechanical robustness and corrosion resistance of the 5052 aluminum alloy with an exquisite mirror-like appearance. Ideal for applications demanding both aesthetic appeal and structural durability, the 5052 mirror aluminum coil is widely used across decorative, architectural, automotive, and marine industries.

Detailed Chemical Composition of 5052 Aluminum Alloy

| Element | Weight % (Typical) | Purpose |

|---|---|---|

| Aluminum (Al) | Balance (~97.25%) | Base metal |

| Magnesium (Mg) | 2.2 - 2.8% | Enhanced strength and corrosion resistance |

| Chromium (Cr) | 0.15 - 0.35% | Increases resistance to corrosion and improves protection against saltwater |

| Manganese (Mn) | ≤ 0.1% | Strengthening element |

| Iron (Fe) | ≤ 0.4% | Impurity, minor influence |

| Copper (Cu) | ≤ 0.1% | Improves strength but limited to avoid corrosion sensitivity |

| Silicon (Si) | ≤ 0.25% | Enhances strength and casting properties |

Features of 5052 Mirror Aluminum Coil

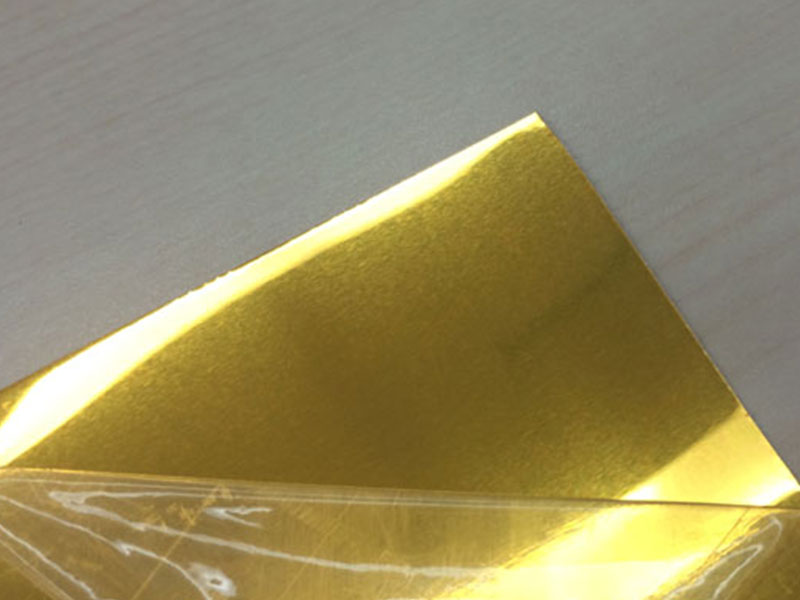

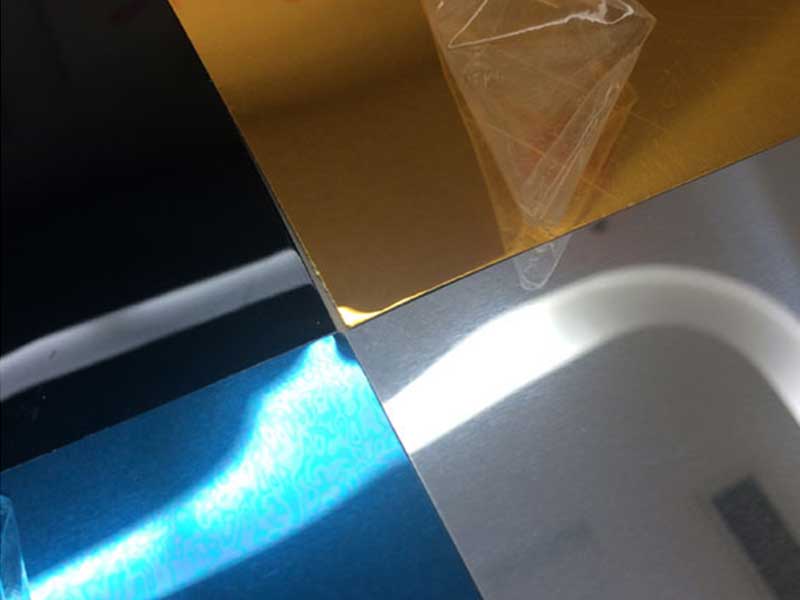

1. Mirror Finish Surface

- Rice-polished or buff-polished to achieve a reflective, mirror-like surface,

- Provides excellent visibility and aesthetic enhancement with high gloss and uniform clarity.

2. High Corrosion Resistance

- Notably resistant to saltwater and marine atmospheres, thanks to magnesium and chromium elements,

- Suitable for harsh environmental exposure including humid or coastal areas.

3. Exceptional Mechanical Properties

- Good tensile strength (195-228 MPa) ensuring durability,

- Balanced ductility allows easy forming and bending without cracking.

4. Lightweight & Eco-Friendly

- Weighs significantly less than steel while maintaining strength, enabling weight reduction in various applications,

- Fully recyclable, supporting sustainable manufacturing processes.

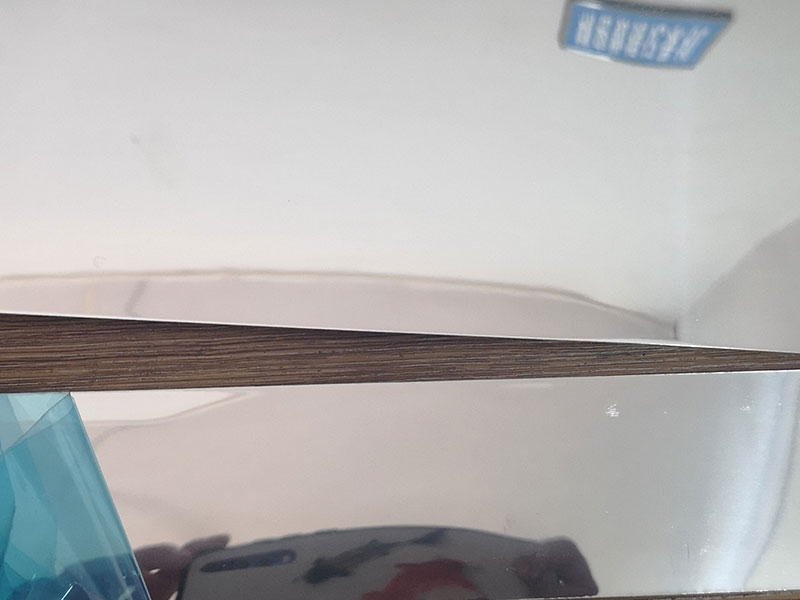

5. Excellent Workability & Fabrication

- Can be cut, welded, stamped, and drawn easily with minimal surface impairment,

- Flatness and tight gauge tolerance assure precision fit during assembly or design modification.

Mechanical Properties (Typical for 5052 Alloy - H32 Temper)

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength (MPa) | 195 - 228 | ASTM B 209 |

| Yield Strength (MPa) | 90 - 155 | |

| Elongation at break (%) | 8 - 18 | |

| Hardness (HV) | ~70 | |

| Density (g/cm³) | 2.68 |

Applications of 5052 Mirror Aluminum Coil

Architectural Applications

- Interior and exterior wall facades,

- Ceiling panels and column covers,

- Decorative railings, store signs, and claddings,

- Elevator panels and doors, escalator finishes.

Transportation & Automotive

- Trim parts, panels with premium mirror finish accents,

- Boat components, marine fixtures given excellent saltwater corrosion resistance,

- RV and trailer body Aesthetic surface options.

Household & Consumer Products

- Kitchen equipment surfaces such as dishwasher fronts, refrigerators, lockers,

- Reflective lightweight surfaces for appliances.

Lighting & Reflectors

- High reflectivity surfaces in lighting fixtures,

- Mirrors and decorative elements in light boxes.

Why Choose 5052 Mirror Aluminum Coil?

- Enhanced durability with resistance against cracking,

- Highly attractive polished surface for prestigious décor and industry standards,

- Solid combination of time-tested corrosion resistance and aesthetic finery,

- High adaptability to post-processing methods increases speakability in diverse industry frameworks.

https://www.aluminumplate.net/a/5052-mirror-aluminum-coil.html