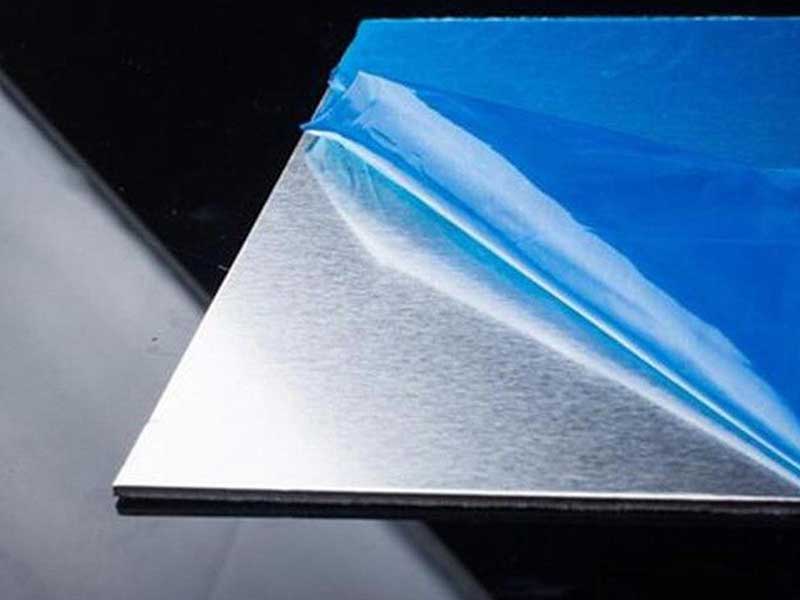

6005 alloy metal aluminum sheet plate

The 6005 alloy aluminum sheet plate is an excellent choice for a wide range of applications due to its superior strength and performance. This alloy belongs to the 6000 series of alloys and primarily consists of silicon and magnesium as its alloying elements. Known for its enhanced corrosion resistance, weldability, and good mechanical properties, the 6005 alloy is particularly ideal for structural applications.

Features

- High Strength: Offers comparable strength when compared to other alloys, making it suitable for structural needs.

- Enhanced Corrosion Resistance: Specially formulated to resist oxidation and chemical exposure.

- Excellent Weldability: Can be welded easily using several welding techniques, ideal for various manufacturing processes.

- Thermal Conductivity: Good thermal conductivity properties, allowing it to maintain integrity under thermal stress.

- Lightweight: Features a favorable strength-to-weight ratio, facilitating ease of transport and installation.

Applications

The versatility of the 6005 alloy aluminum sheet plate extends to various sectors, including:

- Construction: Used commonly for structural steels, roofs, and siding applications.

- Transportation: Essential in creating components for rail, highways, and similar infrastructure.

- Manufacturing: Widely used for custom aluminum parts and fabrication.

- Marine: Provides reliable structural integrity in marine applications where seawater interaction is imminent.

- Electrical: Serves well in electrical applications due to its conductivity properties.

Technical Specifications

The following tables summarize the technical specifications and characteristics of the 6005 alloy aluminum sheet plate.

Physical Properties

| Property | Value |

|---|---|

| Density | 2.70 g/cm³ |

| Melting Point | 655 °C |

| Boiling Point | 2519 °C |

| Thermal Conductivity | 150 W/mK |

| Modulus of Elasticity | 69 GPa |

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Silicon (Si) | 0.6 - 1.0 |

| Magnesium (Mg) | 0.5 - 1.0 |

| Iron (Fe) | 0.0 - 0.5 |

| Manganese (Mn) | 0.0 - 0.3 |

| Zinc (Zn) | 0.0 - 0.25 |

| Copper (Cu) | 0.0 - 0.1 |

| Chromium (Cr) | 0.0 - 0.1 |

| Titanium (Ti) | 0.0 - 0.1 |

| Other Elements | 0.0 - 0.15 |

Alloy Tempering Conditions

| Tempering Code | Characteristics |

|---|---|

| T5 | Age Straightened Tempered - good mechanical properties, has not been heat treated. |

| T6 | Solution Heat Treatment + Aging - excellent yield strength. |

| T0 | Annealed - provides formability; however, lower strength than hardened states. |

Advantages and Disadvantages

Advantages:

- Relatively lightweight without compromising integrity.

- High resistance to permanent deformation.

- Suitable for hard-working environments due to improved ductility.

Disadvantages:

- Subject to fatigue failure under continuous dynamically varying stress.

- Lower corrosion resistance compared to marine-specific aluminum alloys, such as 5083.

https://www.aluminumplate.net/a/6005-alloy-metal-aluminum-sheet-plate.html