Long run length aluminum thermal CTP plate

In the fast-evolving world of printing technology, the quest for efficiency, precision, and durability often leads engineers and industry professionals to innovative materials. Among these, the lesser-discussed yet highly impactful component is the Long Run Length Aluminum Thermal Computer-To-Plate (CTP) Plate. From a strategic perspective rooted in operational sustainability and cost-effectiveness, the nuances of these aluminum plates reveals why they are more than just an ink receptacle—they are a cutting-edge catalyst for print quality and maintenance optimization.

The Unique Role of Aluminum in Thermal CTP Plates

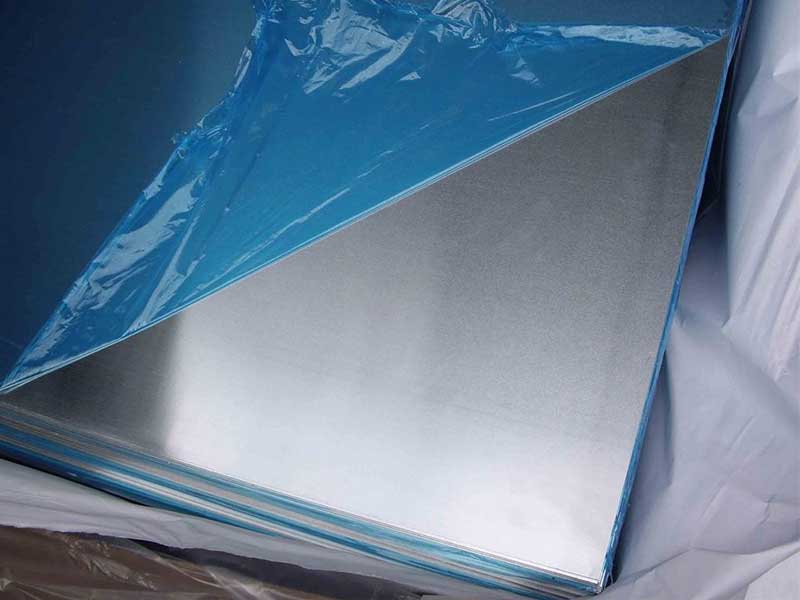

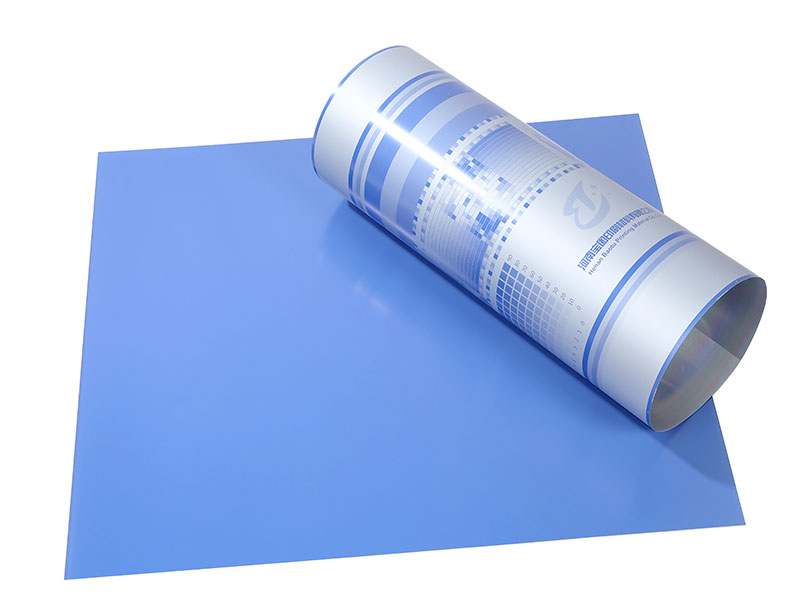

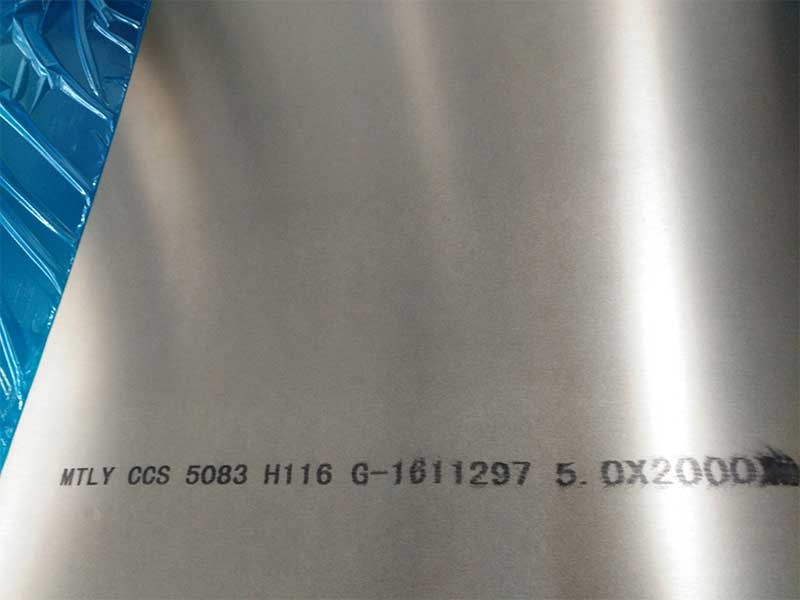

Aluminum's inherent qualities—lightweight, machinability, and corrosion resistance—have long established its prominence in CTP plates. Specifically, aluminum thermal plates leverage oil-based or laser-activated coatings that selectively alter surface properties under thermal exposure, creating a printable image with high fidelity. This precision makes them indispensable for high-volume, consistent runs.

From the vantage point of operational economics, the long run length attribute embodies a material engineered to withstand an extensive number of printing cycles before replacement. This design consideration directly addresses a crucial challenge: minimizing downtime and the overhead associated with plate changes.

These plates are characterized by:

Enhanced Surface Stability: Their resistant coating layers and structural integrity slow down the wear process caused by mechanical rubbing and chemical contact during printing, significantly extending ink transfer consistency over prolonged usage.

Superior Thermal Resistance: As the core of their functionality depends on thermal activation, these plates are optimized to maintain their surface properties under sustained, high-temperature conditions, thereby reducing distortion and topographical shifts that compromise image quality over extended runs.

Material Homogeneity and Surface Finish: The high-quality aluminum substrates feature uniform surface morphology, which—along with specialized surface hardening treatments—further reduce abrasion and scratches, indicative of less plate degradation over tens of thousands of impressions.

From a Practical Standpoint: Reliability and Cost-Savings

Durability Equals Reliability: For high-volume printing operations—think display ads, book publishing, or packaging—schedule disruption due to frequent plate changes translates into logistical costs, manpower hours, and quality variability. Long run length aluminum thermal plates mitigate these issues, offering consistent performance throughout the press run, reducing variations, and ensuring print fidelity.

Economic Efficiency: While the initial investment in specialized, high-performing aluminum plates may be higher than standard alternatives, the long-term benefits are compelling. Fewer plate changes mean less labor, less material waste, and decreased machine downtime—all conspicuously translating to cost savings.

Being Smart About Selection: Factors for Industry Precision

Choosing the right long run length aluminum thermal plate requires balancing several considerations:

Thermal Conductivity: Ensures rapid and uniform thermal response, critical for large-volume runs.

Coating Durability: Resistance to chemicals used during washing or blanket cleaning reduces premature deterioration.

Mechanical Robustness: Resistance to scratching and abrasion prolongs the plate’s usable lifespan.

Compatibility: Ensure that the plates are compatible with existing thermal CTP systems and water-based or gum-type developing processes.

The Future: The Sustainable Edge

Another distinctive perspective on high-quality aluminum thermal plates is their sustainability angle. Their extended run lengths mean fewer resources dedicated to manufacturing, handling, and disposal over their lifecycle—aligning with the industry's shift towards more eco-friendly processes. Additionally, their recyclable nature ensures that their environmental impact remains minimal.

Final Thoughts

Broadening the viewpoint from mere material properties to practical sustainability and fiscal prudence, long run length aluminum thermal CTP plates emerge as an exemplary intersection of engineering excellence and strategic operational planning. Their durability translates directly into business reliability, quality assurance, and cost management for high-volume print environments.

In an era where competitive pressure requires optimized productivity, and investing in such precision-engineered aluminum plates push the boundaries of what printing operations can achieve—longer runs, better quality, and a lower environmental footprint.

https://www.aluminumplate.net/a/long-run-length-aluminum-thermal-ctp-plate.html