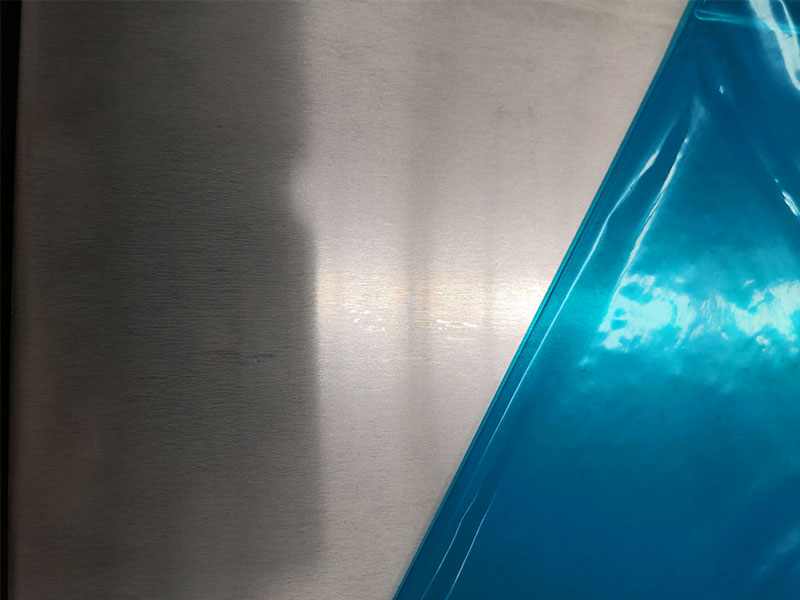

6mm 5083 aluminum sheet for auto

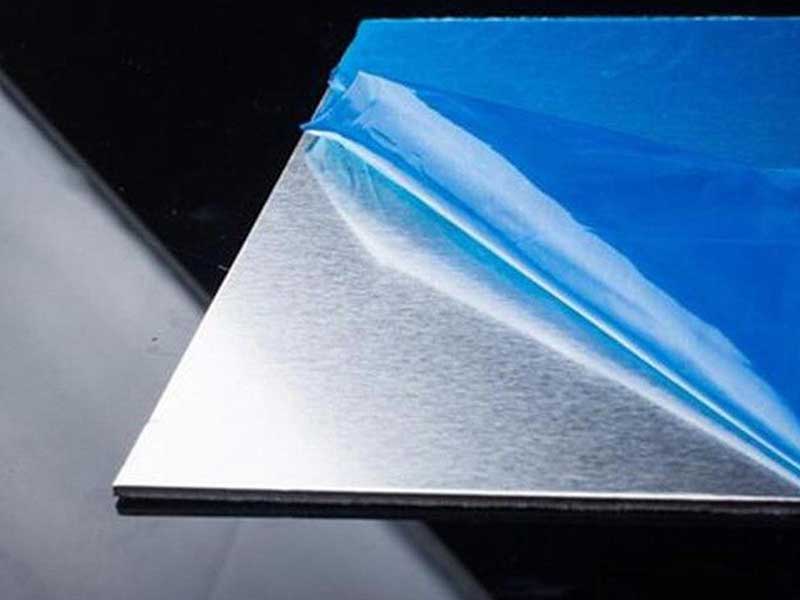

The 5083 aluminum sheet is a vital component in a wide array of industries, particularly the automotive sector.

5083 aluminum alloys fall under the classification of wrought aluminum, known primarily for their exceptional performance under extreme environmental stress and excellent corrosion resistance. The major alloying elements present in 5083 are magnesium and manganese, which enhance its strength and ductility.

Functions of 6mm 5083 Aluminum Sheet

Functions

- Durability: 5083 aluminum sheets exhibit a high strength-to-weight ratio, making them ideal for structural components.

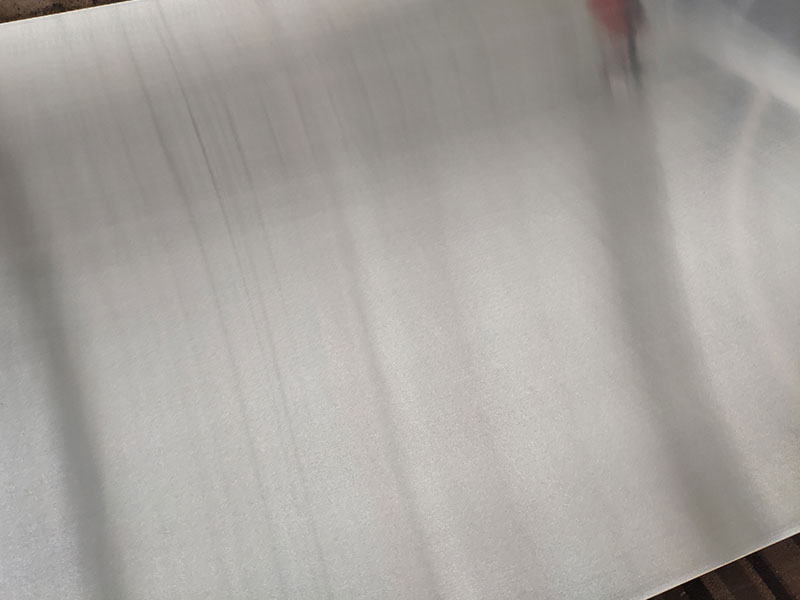

- Corrosion Resistance: This alloy is highly resistant to seawater and corrosive environments, ensuring longevity in automotive applications.

- Weldability: Excellent weldability allows the 5083 alloy to be tailored for various designs and functionalities.

- Formability: The alloy can be formed into complex shapes without losing its mechanical properties.

Applications in Automotive Industry

Due to its unique properties, the 6mm 5083 aluminum sheet is used in several automotive applications, which include:

- Body Components: Used in vehicle exteriors to reduce weight without compromising strength.

- Structural Components: Employed in cross members, supports, and bracing because of its robustness.

- Heat Exchangers: Applied in radiators and subtle heat exchangers where thermal conductivity is crucial.

- Specialty Trailers: Utilized in the manufacturing of lightweight trailers for hauling without worrying about excess weight.

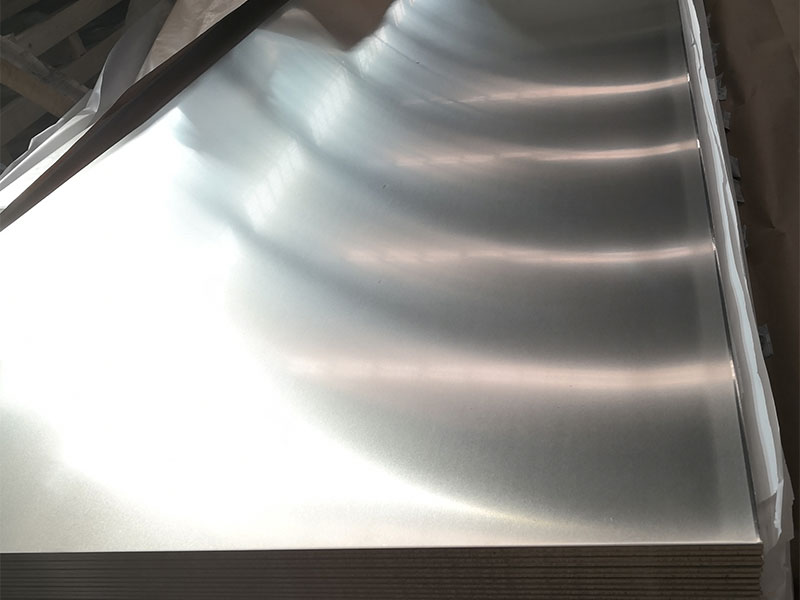

Technical Details

Below is a structured comparison highlighting relevant physical properties, chemical composition, and standards applicable for the 6mm 5083 aluminum sheet.

Chemical Composition of 5083 Aluminum Sheet

| Element | Chemical Composition (%) |

|---|---|

| Aluminum (Al) | Balance (min 90.7) |

| Magnesium (Mg) | 4.0 – 4.9 |

| Manganese (Mn) | 0.4 – 1.0 |

| Copper (Cu) | 0.0 – 0.1 |

| Silicon (Si) | 0.0 – 0.4 |

| Zinc (Zn) | 0.0 – 0.25 |

| Titanium (Ti) | 0.0 – 0.1 |

| Chromium (Cr) | 0.05 – 0.25 |

Technical Specifications

| Property | Value |

|---|---|

| Thickness | 6 mm |

| Width | Up to 2 meters |

| Length | Customizable |

| Density | 2.66 g/cm³ |

| Yield Strength | ≥ 207 MPa |

| Tensile Strength | ≥ 310 MPa |

| Elongation | ≥ 8% |

| Fatigue Strength | 120 – 170 MPa |

| Thermal Conductivity | ~ 165 W/mK |

| Electrical Conductivity | 30% IACS |

Implementation Standards

The manufacturing and application of the 5083 aluminum sheet adhere to various international standards, including:

- ASTM B209: Specification for Aluminum and Aluminum-Alloy Sheets and Plates.

- EN 573: Aluminium and Aluminium Alloys — Chemical Composition and Form of Wrought Products.

- ISO 6361: Wrought Aluminum and Aluminum Alloys–Specifications for Products.

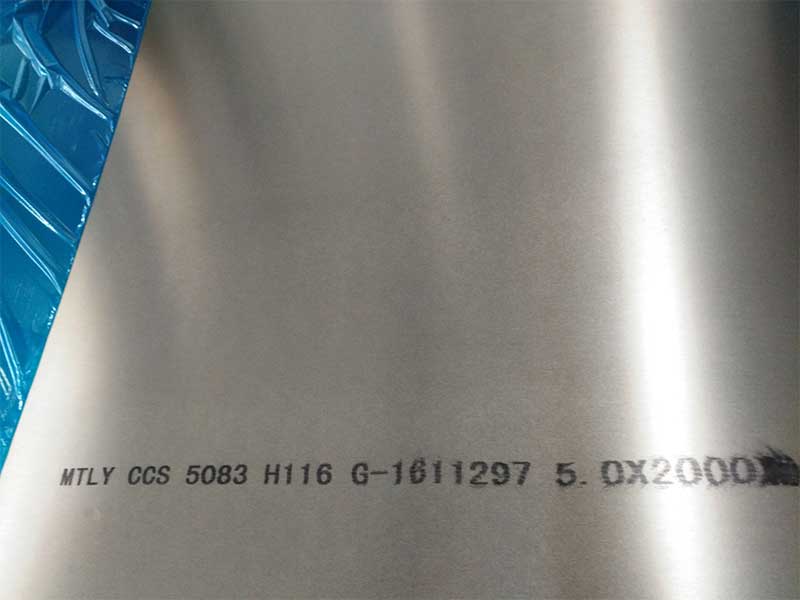

Alloy Tempering Conditions

The heat treatment conditions for 5083 common tempering (like H111 or H116) may involve:

| Tempering Condition | Description |

|---|---|

| H111 | Solution heat-treated and lacquered |

| H116 | Higher-strength solution heat-treated follow-ups |

https://www.aluminumplate.net/a/6mm-5083-aluminum-sheet-for-auto.html