Insulation aluminum jacketing roll

When it comes to industrial insulation solutions, insulation aluminum jacketing rolls stand as a high-performing, aesthetically pleasing choice. These products are often overshadowed by their more commonplace counterparts, yet they possess distinct advantages ideal for specific applications in various sectors.

What is Insulation Aluminum Jacketing?

At its core, insulation aluminum jacketing is a type of covering used primarily to insulate pipes and ducts, protecting the interior insulation from environmental damages while affording aesthetic and functional benefits. Made from rolled aluminum, these jackets are available in a wide range of finishes, thicknesses, and lòng (consistent with different alloy choices).

Distinctive Properties of the Material

Durability: Aluminum is even more resilient than steel when it comes to providing a protective shield against corrosion and moisture. This characteristic makes aluminum jackets exceptionally long-lasting.

Thermal Conductivity: With excellent thermal properties, aluminum effectively reflects heat, making it a great asset for thermal insulation in both hot and cold conditions.

Lightweight Nature: The lightweight profile of rolled aluminum enables easy handling and installation, reducing overall labor costs.

Specifications and Parameters

Before diving into specifications, it's important to understand standard dimensions you'll typically find:

- Thickness: Generally ranging from 0.016" to 0.040" (0.4 mm to 1.0 mm)

- Width: Varies from 36" to 48" rolls; custom widths also available.

- Length: Typically available in 100 to 150 ft rolls.

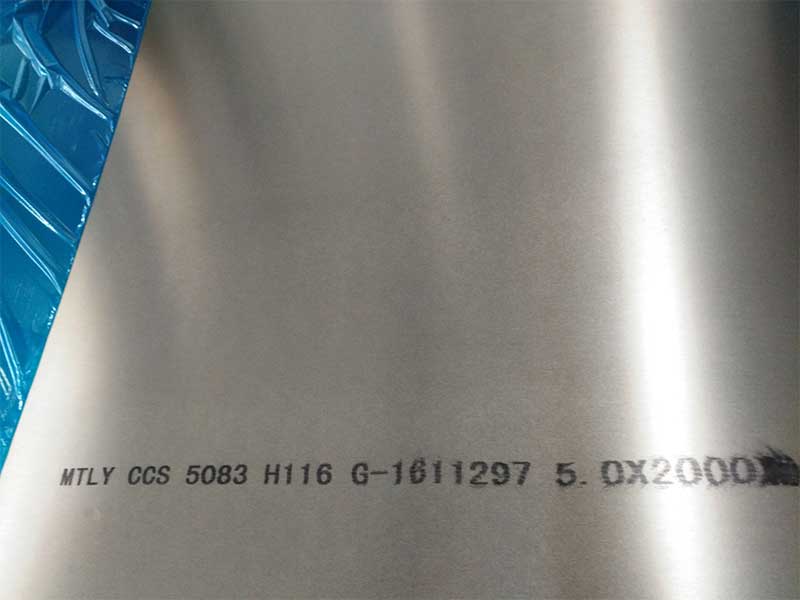

Alloy Tempering

The choice of alloy ensures not only durability but adaptability to specific industrial needs. Below are some common aluminum alloys used' alongside their temper designations:

| Alloy Type | Temper | Purpose |

|---|---|---|

| 3003 | H14 | Good formability and corrosion resistance, ideal for most insulation applications. |

| 1100 | H14 | High corrosion resistance and thermal properties combined with excellent formability; it reflects heat effectively. |

| 5005 | H32 | Maintains excellent rigidity while still offering considerable corrosion resistance. |

Corporately recognized tempering codes like “H14,” indicate they have been cold worked to achieve specific mechanical properties without altering the main metal's characteristic.

Implementation Standards

Compatibility with established safety and performance standards is crucial for any fitness solution used in industry. Insulation aluminum jacketing aligns with various guidelines such as:

- ASTM C1729: Specifies materials and performance criteria necessary for types of insulation coverings.

- ASME IPC: Provides high standards for flue erector constructions and durability in mechanical insulation.

Using covering materials resistant to environmental and operational impacts, as defined by these implementations, guarantees not just performance but safety.

Chemical Properties

| Substance | Resistance Level |

|---|---|

| Hydrocarbons (e.g., Oils, Fuels) | Good |

| Acids (most kinds, mild | Moderate |

| Alkalias | Moderate |

| Sea Water | Good Resistance for at Least Aluminium |

| UV Radiation | Low Impact (need protective coatings) |

These chemical properties make insulation aluminum jacketing suitable for environments ranging from chemical processing plants to oil extraction systems.

https://www.aluminumplate.net/a/insulation-aluminum-jacketing-roll.html