Aluminum Sheet Mirror Float Glass 1.8mm

High-clarity reflective aluminum sheet designed to match mirror float glass aesthetics at just 1.8 mm thickness.

Aluminum Sheet Mirror Float Glass 1.8mm is a lightweight, highly reflective aluminum mirror sheet engineered to deliver the visual clarity of float glass mirrors with the strength, formability, and corrosion resistance of aluminum. Ideal for interior decoration, lighting reflectors, signage, cosmetic panels, and transportation interiors, this sheet combines a glass-like mirror finish with easy fabrication and excellent durability. Typical alloys such as 1050, 1060, or 1100 provide high reflectivity, while optional protective films, coatings, and backing layers ensure long service life in demanding environments.

Aluminum Sheet Mirror Float Glass 1.8mm is a precision-rolled aluminum sheet that has been polished and/or coil-coated to achieve a mirror-like surface comparable to traditional float glass mirrors.

Where conventional glass is heavy and brittle, this mirror aluminum offers:

- Extremely low weight

- Excellent impact resistance

- Easy cutting, bending, and forming

- Safe handling without the risk of shattering

At 1.8 mm thickness, it provides a strong yet flexible substrate that can be mounted, laminated, or integrated into assemblies where traditional mirror glass would be too fragile or too heavy.

Features

| Feature | Description |

|---|---|

| Mirror-like reflectivity | Bright, highly polished surface comparable to float glass mirror reflection |

| Lightweight construction | Up to about one-third the weight of glass at similar thickness |

| Improved safety | No shattering; reduces injury risk in public and high-traffic spaces |

| Easy fabrication | Can be sheared, laser-cut, bent, stamped, or CNC machined |

| Corrosion resistance | Natural oxide film provides good atmospheric corrosion resistance |

| Thickness stability | Nominal 1.8 mm thickness with tight tolerances for consistent flatness and stiffness |

| Optional protective film | PE or PET film on the mirror side to protect from scratches during transport and processing |

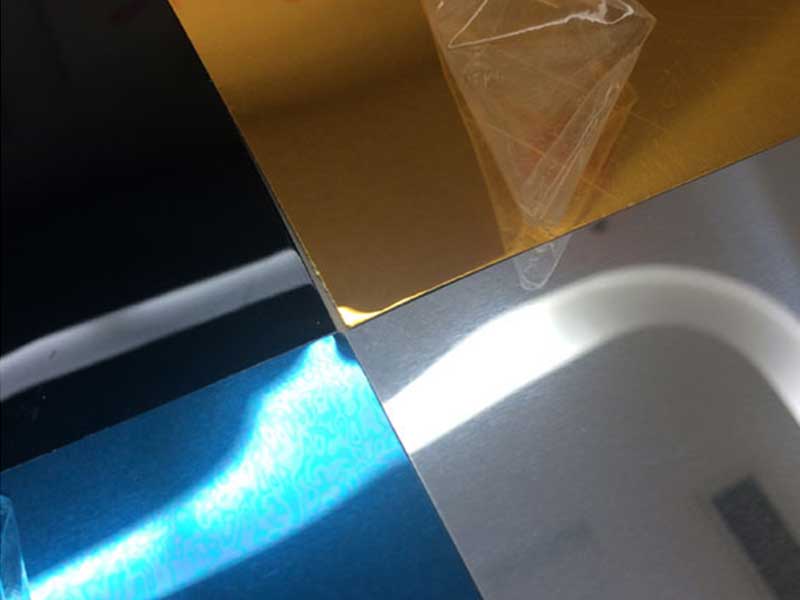

| Versatile finish options | Standard bright mirror, super-mirror (high-gloss), or tinted/colored mirror surfaces |

Typical Applications

| Application Area | Typical Uses |

|---|---|

| Interior decoration | Wall panels, ceiling tiles, column cladding, furniture accents, display cases |

| Signage & branding | Logo backplates, display boards, point-of-sale fixtures, exhibition stands |

| Lighting & optics | Lamp reflectors, light guides, decorative luminaires, indirect lighting panels |

| Transportation | Bus and train interiors, elevator cabins, caravan and RV cabinets, ship cabins |

| Retail & cosmetics | Cosmetic display racks, mirror panels in stores, product shelving fronts |

| Industrial & safety | Equipment guards, machine covers, reflective panels in control rooms |

Alloy Options and Temper

Mirror aluminum sheets are often produced from high-purity or general-purpose non-heat-treatable alloys that respond well to polishing and anodizing.

| Item | Typical Options | Notes |

|---|---|---|

| Alloy grade | 1050, 1060, 1100, 3003 | 1xxx for highest reflectivity, 3003 for better strength |

| Temper | H14, H18, H24 | Cold-worked tempers for stiffness and surface stability |

| Standard thickness | 1.8 mm nominal | Other thicknesses available on request |

| Width range | Approx. 500–1500 mm | Custom widths possible depending on production line |

| Length format | Coil or cut-to-length sheets | Sheets supplied with protective film on mirror side |

Typical Chemical Composition

Example composition for 1050 and 1060 mirror aluminum (for reference; actual values may vary slightly by supplier and specification).

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Al (min %) |

|---|---|---|---|---|---|---|---|---|

| 1050 | ≤ 0.25 | ≤ 0.40 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.05 | ≤ 0.03 | ≥ 99.50 |

| 1060 | ≤ 0.25 | ≤ 0.35 | ≤ 0.05 | ≤ 0.03 | ≤ 0.03 | ≤ 0.05 | ≤ 0.03 | ≥ 99.60 |

| 1100 | 0.00–0.95 | ≤ 1.00 | ≤ 0.20 | ≤ 0.05 | — | ≤ 0.10 | — | ≥ 99.00 |

High aluminum purity contributes to excellent optical reflectivity and a clean, bright finish after polishing.

Technical Specifications

Dimensional and Physical Properties

| Parameter | Typical Value / Range |

|---|---|

| Thickness | 1.8 mm nominal |

| Thickness tolerance | ±0.06–0.10 mm (depending on standard/width) |

| Standard width | 1000 / 1219 / 1250 mm (custom on request) |

| Length (sheet) | 2000–4000 mm typical |

| Density (approx.) | 2.70 g/cm³ |

| Areal weight @ 1.8 mm | ≈ 4.86 kg/m² |

| Surface finish | Bright mirror / high-gloss / super-mirror |

| Surface protection | Single-side PE or PET film on mirror face |

Mechanical Properties (Reference for 1050-H24 / 1060-H24)

| Property | Typical Value |

|---|---|

| Tensile strength | 105–145 MPa |

| Yield strength (0.2% offset) | 80–120 MPa |

| Elongation (A50) | 2–10 % (depending on gauge and alloy) |

| Modulus of elasticity | ≈ 70 GPa |

| Brinell hardness (HB) | 25–35 |

Values above are representative and may vary with alloy, temper, and production route.

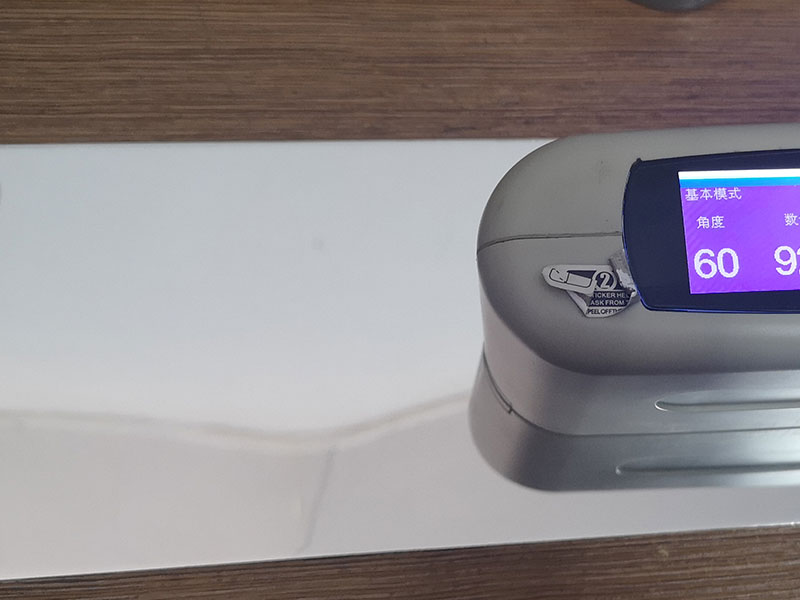

Optical and Surface Characteristics

| Property | Typical Range / Description |

|---|---|

| Total reflectivity | ≈ 83–87 % (bright mirror aluminum, visible spectrum) |

| Gloss (60° angle) | High gloss, often > 80 GU, depending on process |

| Surface roughness Ra | Typically < 0.3 µm for mirror-grade finishes |

| Color tone | Silver, with optional colored or tinted film/coating variants |

Processing and Fabrication

| Operation | Suitability / Notes |

|---|---|

| Cutting | Shearing, sawing, punching, and CNC routing all suitable; use sharp tooling |

| Bending | Good formability; recommended larger bend radius to protect mirror surface |

| Stamping | Possible with proper die design and surface protection |

| Laser cutting | Feasible; mirror side should be protected from spatter and thermal marking |

| Welding | Possible for many alloys, though visible seam may affect appearance |

| Adhesive bonding | Widely used for mounting to substrates such as MDF, composite panels, and plastics |

To preserve the mirror finish, protective film is kept on during fabrication and removed only after final installation.

Surface Protection and Coatings

| Option | Description |

|---|---|

| Standard PE film | Clear or white PE film applied to mirror side for scratch protection |

| High-adhesion PET film | For deep forming or longer storage and transport cycles |

| Back-side coating | Primer, paint, or adhesive-ready coatings available on request |

| Anodized mirror finish (optional) | Enhanced corrosion and wear resistance, slightly different optical tone |

Advantages Compared with Mirror Float Glass

| Aspect | Mirror Aluminum Sheet 1.8mm | Traditional Mirror Float Glass |

|---|---|---|

| Weight | Very light (≈ 4.86 kg/m² at 1.8 mm) | Heavy (≈ 4.5–5.0 kg/m² at 2–3 mm glass) |

| Breakage | High impact resistance, no shattering | Brittle, can break into sharp fragments |

| Fabrication | Easy cutting, bending, forming | Limited to cutting and edge finishing |

| Installation | Simple mounting, reduced support requirements | Requires strong frames and careful handling |

| Safety | Safer in public, transport, and children’s areas | Higher risk of injury if broken |

Handling, Storage, and Maintenance

| Aspect | Recommendations |

|---|---|

| Handling | Keep the protective film intact during processing; avoid sliding sheets on each other |

| Cleaning | Use soft cloth with mild, non-abrasive detergent; avoid strong alkalis or abrasive pads |

| Protection | Remove protective film only after installation to minimize surface damage |

Ordering Information

When specifying Aluminum Sheet Mirror Float Glass 1.8mm, it is helpful to define:

| Parameter | Example Specification |

|---|---|

| Alloy | 1060 |

| Temper | H24 |

| Thickness | 1.8 mm |

| Width × Length | 1220 × 2440 mm (or coil width if in coil form) |

| Surface finish | Bright mirror, single-side |

| Protection | PE film on mirror side |

| Back-side condition | Mill finish or coated |

| Quantity & packaging | Palletized sheets, vertical or horizontal pack |

This combination of mirror-glass appearance, low weight, and excellent processability makes Aluminum Sheet Mirror Float Glass 1.8mm an ideal choice for modern, safe, and visually striking designs across architecture, transportation, and industrial applications.

https://www.aluminumplate.net/a/aluminum-sheet-mirror-float-glass-18mm.html