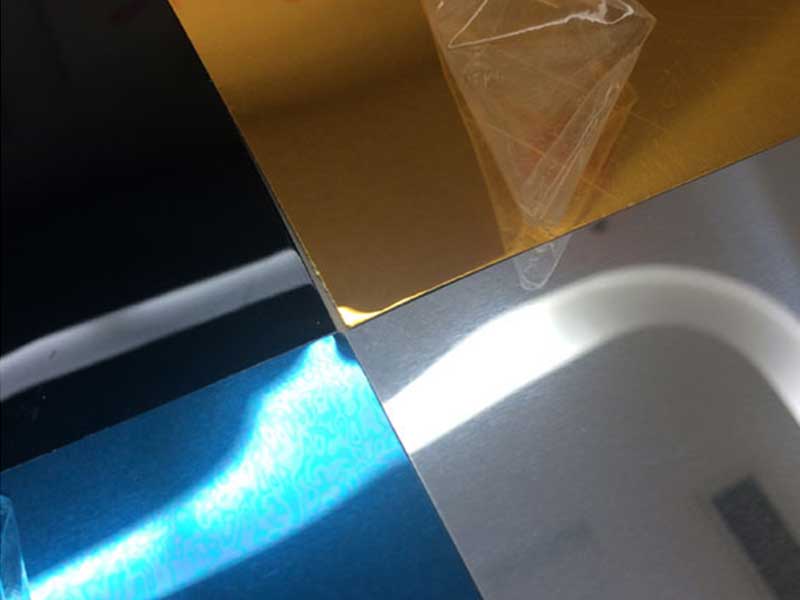

Double coated polished mirror finish aluminum sheets

Double coated polished mirror finish aluminum sheets represent a premium-quality aluminum product designed to meet the highest standards for aesthetics, durability, and functionality. With a brilliantly smooth, reflective surface, these sheets grant striking visual appeal combined with exceptional protection, making them ideal for various architectural, decorative, and industrial applications.

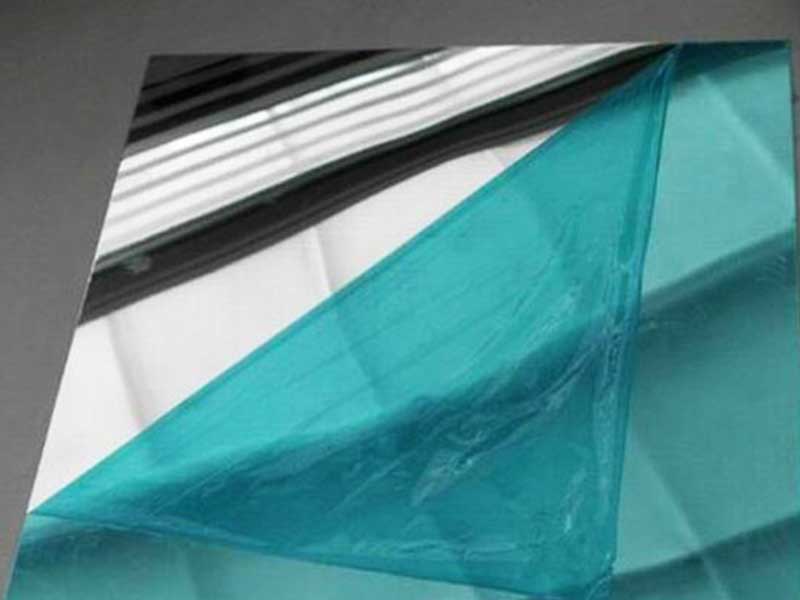

These aluminum sheets undergo a precise surface polishing process to attain a mirror-like finish that dazzles with near-perfect reflectivity. The polished side is then protected during storage and transportation by a carefully engineered double-layered protective coating film. This double coating ensures the sheet's surface remains free from scratches, dirt, and mechanical damage before installation.

Engineered for strength, corrosion resistance, and exceptional surface quality, these sheets are favored for environments requiring both enhanced aesthetics and material performance.

Features

- Brilliant Mirror Finish: Perfectly polished surface with reflective clarity close to glass mirrors, delivering high-end visual effect.

- Double Protective Coating: Both sides of the sheet are protected by plastic films to prevent damage prior to use.

- Corrosion Resistant: High-quality aluminum alloy substrates provide outstanding resistance to oxidation and weathering.

- High Strength-to-Weight Ratio: Lightweight metal combined with substantial mechanical strength.

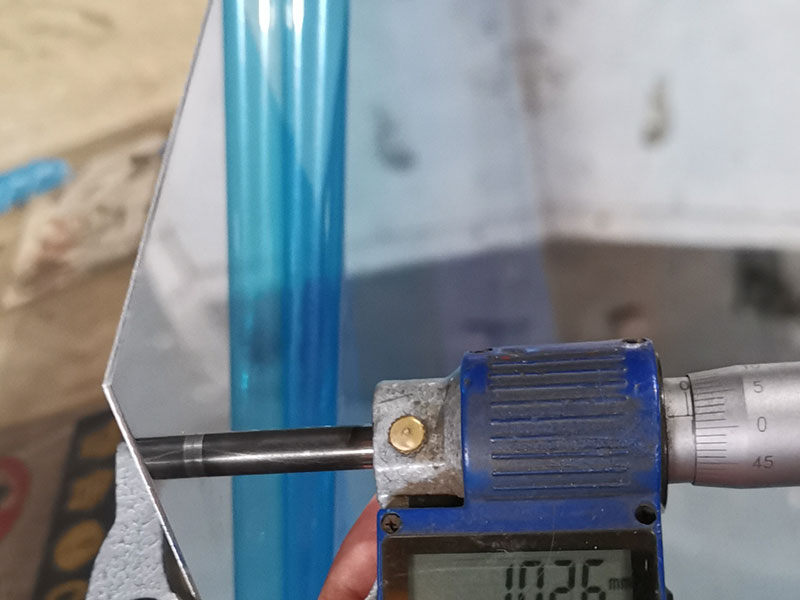

- Precision Flatness and Thickness Tolerance: Ideal for demanding applications requiring dimensional accuracy.

- Ease of Fabrication: Suitable for bending, cutting, welding, and forming operations.

- Non-Tarnishing: Durable finish maintains reflectivity without oxidization under normal atmospheric conditions.

Chemical Composition

The polished mirror finish sheets are primarily produced from high-grade aluminum alloys noted for their excellent surface finish capability along with superior corrosion resistance. Typical aluminum alloys used include 1xxx, 3xxx, and 5xxx series.

| Element | Al 1xxx Series (%) | Al 3xxx Series (%) | Al 5xxx Series (%) |

|---|---|---|---|

| Aluminum (Al) | 99.00 - 99.9 | 94.00 - 96.00 | 90.00 - 95.00 |

| Silicon (Si) | Max 0.25 | Max 0.70 | Max 0.40 |

| Iron (Fe) | Max 0.40 | Max 0.70 | Max 0.40 |

| Copper (Cu) | Max 0.05 | Max 0.05 | Max 0.10 |

| Manganese (Mn) | Max 0.03 | 1.00 - 1.50 | 0.10 - 0.50 |

| Magnesium (Mg) | - | - | 3.00 - 5.00 |

| Zinc (Zn) | Max 0.05 | Max 0.20 | Max 0.25 |

| Titanium (Ti) | Max 0.06 | Max 0.10 | Max 0.10 |

Technical Specifications

| Property | Value / Range | Unit | Remarks |

|---|---|---|---|

| Thickness Range | 0.2 – 3.0 | mm | Custom thickness available |

| Sheet Width | 1000 – 1500 | mm | Standard width range |

| Sheet Length | 2000 – 6000 | mm | Customized lengths offered |

| Surface Finish | Polished mirror / Reflective | Visual Rating | 90%+ reflectivity |

| Protective Coating | Double coated PE/PVC film | - | Removable plastic protective film |

| Tensile Strength (Al 5xxx alloys) | 180 – 350 | MPa | Depending on alloy temper and treatment |

| Elongation | 5 – 12 | % | Illustrates ductility |

| Density | 2.7 | g/cm³ | Standard Aluminum density |

| Corrosion Resistance | Excellent | Qualitative | Suitable for outdoor exposure |

Performance & Durability

These polished mirror finish sheets excel in harsh environments requiring excellent corrosion resistance alongside surface durability. The precision polishing and double coating protect against pitting, acid rain, and dust ingress. Additionally, the aluminum substrate can undergo anodizing post-polish for further protection in marine or acidic atmospheres.

Typical Applications

Double coated polished mirror finish aluminum sheets are used extensively where aesthetic appeal merges with long-lasting performance:

| Sector | Typical Uses |

|---|---|

| Architecture | Facade cladding, wall panels, ceilings |

| Interior Design | Decorative panels, partitions, furniture surfaces |

| Elevators & Escalators | Door trims, interior car finishes |

| Electronics | Reflective shielding, enclosures |

| Kitchen & Household Appliances | Paneling for high-end kitchen appliances |

| Automotive | Trim parts, decorative elements |

| Signage & Advertising | Reflective sign boards, illuminated displays |

Handling and Conservation Recommendations

- Keep protected by the double coating films until final installation or fabrication to avoid surface damage.

- Store sheets flat in a covered, dry space away from chemicals or abrasive material.

- Avoid bending or forming with the protective film in place; remove it carefully just before working on the sheet.

- If required, clean the finish with mild detergent solutions and soft cloth only.

- Avoid aggressive chemical agents, steel brushes, or abrasive cleaning pads that damage the mirror finish.

Double coated polished mirror finish aluminum sheets combine the aesthetic advantages of a brilliant reflective surface with the practical benefits of corrosion resistance and mechanical strength. Thanks to their unique double protective film coating and refined manufacturing processes, they ensure durability and outstanding performance across applications spanning architectural decoration to precision components.

For customers requiring a high-grade aluminum sheet with mirror-like finish and long-term surface integrity, these sheets represent a confident and premium choice.

For detailed order inquiries, alloy selection, and technical assistance, please contact our sales and engineering teams.

https://www.aluminumplate.net/a/double-coated-polished-mirror-finish-aluminum-sheets.html