Alloy 5052 5083 6061 Marine Grade Aluminium Sheet Plate

"Marine grade" is often treated like a badge that magically makes any aluminum survive the sea. In practice, seawater is less a single enemy than a whole environment: chloride ions looking for weak spots, oxygen cycling with wet/dry exposure, galvanic couples created by fasteners, and fatigue loads that never quite stop. From that perspective, choosing between Alloy 5052, 5083, and 6061 marine grade aluminium sheet plate is less about chasing a label and more about matching a metal's personality to a vessel's real life-how it will be welded, how it will be fastened, what it will carry, and how it will age.

These three alloys are common because they cover three different philosophies of marine design. 5052 is the graceful generalist, 5083 is the hard-working hull specialist, and 6061 is the structural multitool. When you see them as characters rather than catalog items, the selection becomes more intuitive and more reliable.

What "marine" really demands from sheet and plate

Marine service pushes aluminum in ways that don't show up in a dry warehouse test. Chlorides attack protective films when they find crevices or stagnant water. Dissimilar metals create galvanic cells. Welds become critical because they are both metallurgically altered zones and geometric stress concentrators. And then there is motion: waves, prop vibration, trailer transport, and docking impacts that convert static strength into a fatigue problem.

That is why the most important marine questions are often practical ones. Can this alloy be welded without losing too much performance? Does it resist pitting and crevice corrosion in splash zones? Is it prone to stress corrosion cracking in certain tempers? Will it be bent, rolled, or deep-formed? Is the plate thick enough to hold shape without oil-canning?

With that in mind, here's how 5052, 5083, and 6061 play their roles.

Alloy 5052: the reliable skin and fabricator's friend

Alloy 5052 is an Al-Mg alloy that earns trust through consistency. It forms easily, tolerates bending and hemming, and has excellent corrosion resistance in marine atmospheres and brackish conditions. If you are making boat interiors, consoles, lockers, tanks, covers, small craft components, or anything that needs to be shaped rather than simply cut and welded, 5052 often feels "right" in the shop.

Its strength is moderate, but it tends to be more than adequate for non-primary structure. It also resists seawater attack well because magnesium in solid solution supports a stable oxide film, especially when good drainage and cleaning practices are used. In sheet gauges, it is a common choice when you need smooth forming and good surface finish.

Typical tempers for marine fabrication include H32 for a balanced combination of strength and formability, and O temper for maximum formability when deep forming is needed.

Alloy 5083: the hull plate that treats waves like a workload

Alloy 5083 is the plate you choose when the sea is not scenery, but duty. Also an Al-Mg alloy, 5083 is designed to carry more load and shrug off more abuse, especially in welded structures. It is widely used for hulls, decks, superstructures, and other primary components where higher strength and strong weld performance matter.

5083 is famous for retaining relatively good properties after welding compared with heat-treatable alloys. In real boats, weld efficiency is not a theoretical number; it becomes the difference between a stiff hull and a "working" hull that flexes and fatigues. With 5083, the softened heat-affected zone is still serviceable for marine structures when designed appropriately.

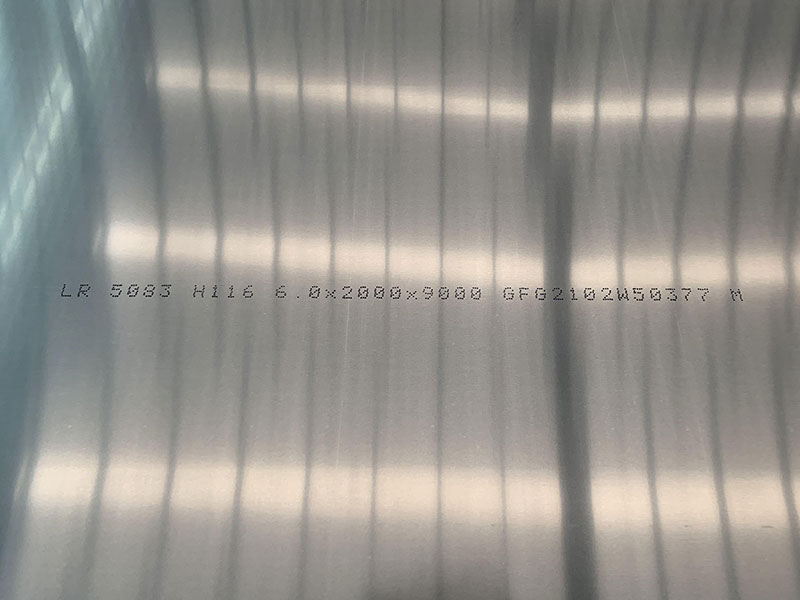

The most common marine temper is H116 or H321, both aimed at improved resistance to exfoliation and stress corrosion in marine environments. When buyers ask for "true marine grade 5083," they usually mean these tempers, along with appropriate quality control for plate flatness and surface condition.

Alloy 6061: the structural bridge between machining and the water

Alloy 6061 is an Al-Mg-Si heat-treatable alloy. It is not the default hull plate for high-performance seawater immersion, but it is an outstanding structural alloy for marine hardware, frames, ladders, brackets, masts, and machined components. If a part must be milled, drilled, tapped, and held to tighter tolerances, 6061 is often the easiest route to a clean, strong result.

The caveat is corrosion behavior and welding. 6061 generally has good corrosion resistance, but in seawater it is more sensitive to pitting and galvanic effects than the 5xxx series, especially around crevices and fasteners. After welding, its strength in the weld zone drops substantially unless post-weld heat treatment is performed, which is uncommon for large fabrications.

So 6061 shines where you can design around these realities: isolate dissimilar metals, avoid crevices, seal joints, use proper coatings or anodizing, and treat welded areas with realistic strength assumptions. The common temper is T6 for maximum strength, while T651 is used for stress-relieved plate for better dimensional stability in machining.

Standards and typical supply expectations

In marine procurement, the alloy is only half the story; the standard and temper lock in performance.

Common standards and references include ASTM B209 for aluminum sheet and plate, EN 485 for European wrought products, and marine-focused tempers such as 5083-H116/H321 and 5052-H32. Classification society requirements may apply depending on vessel type, including additional testing or traceability requirements. Buyers should confirm mill test certificates, heat numbers, and compliance to specified tempers, thickness tolerances, and surface finish.

For welding, typical filler choices include ER5356 for 5xxx-to-5xxx joining, and ER4043 or ER5356 for 6061 depending on strength and cracking considerations, with attention to service temperature and corrosion. Good marine practice also includes isolating stainless fasteners with nonconductive washers, using sealants to avoid crevice corrosion, and avoiding copper-bearing alloys in direct contact with seawater-exposed aluminum.

Chemical composition (typical limits, wt.%)

Actual limits depend on the exact specification revision, but the table below reflects commonly referenced ranges used in industry for these alloys.

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (each/total) | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.10 | ≤0.05 / ≤0.15 | Bal. |

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.4–1.0 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | ≤0.05 / ≤0.15 | Bal. |

| 6061 | 0.40–0.80 | ≤0.70 | 0.15–0.40 | ≤0.15 | 0.8–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | ≤0.05 / ≤0.15 | Bal. |

Typical mechanical properties (room temperature, representative)

Mechanical properties vary by thickness, product form, and standard. Values below are typical, not guaranteed, and should be verified against the applicable specification and mill test report.

| Alloy & temper | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) |

|---|---|---|---|

| 5052-H32 | 215–260 | 160–200 | 10–16 |

| 5083-H116 / H321 | 300–360 | 215–270 | 10–16 |

| 6061-T6 / T651 | 290–320 | 240–276 | 8–12 |

Choosing with a "boat-life" mindset

If your project is mostly formed sheet work with moderate loads, 5052 is often the quiet champion. It behaves well in the shop and ages gracefully in salty air when details like drainage and fastener isolation are handled correctly.

If you are building a welded hull or a heavily loaded marine structure that will live in the splash zone and beyond, 5083 in a marine temper is the workhorse choice. It is not just strong; it is strong in the way welded boats need-tolerant of fabrication realities.

If you need machined structure, stiff frames, precision parts, and strong extruded or plate components, 6061-T6 is hard to beat. Just treat it like a high-performance tool that needs correct corrosion design: coatings where appropriate, thoughtful joint sealing, and careful galvanic isolation.

Marine grade is not a single alloy-it is a relationship between alloy chemistry, temper, fabrication method, and the water you are asking it to survive. When 5052, 5083, and 6061 are chosen for the roles they naturally excel at, aluminum stops being a compromise and starts acting like what it really is: a disciplined material for a restless environment.

https://www.aluminumplate.net/a/alloy-5052-5083-6061-marine-grade-aluminium-sheet-plate.html