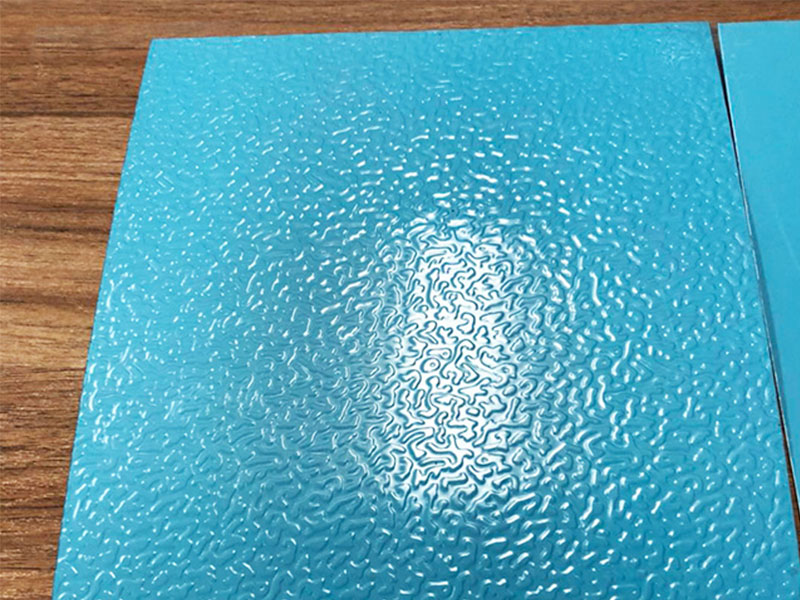

Embossed aluminum sheet 6082

Embossed aluminum sheet 6082 combines the mechanical strength of 6082 alloy with the functional and decorative advantages of an embossed (patterned) surface. It is widely used where anti-slip, durability, corrosion resistance, and an attractive appearance are required, such as in transportation, construction, flooring, and equipment cladding.

6082 is a heat-treatable Al-Mg-Si alloy with relatively high strength among the 6xxx series, good corrosion resistance, and decent weldability. When processed into an embossed sheet (such as diamond, orange peel, stucco, or other patterns), it offers enhanced aesthetics and slip resistance.

Attributes:

| Item | Description |

|---|---|

| Alloy | 6082 (Al-Mg-Si series) |

| Temper (typical) | O, T4, T5, T6, T651, etc. |

| Surface pattern | Stucco / Orange peel / Diamond / Lentil / Classic embossed textures |

| Surface treatment | Mill finish, anodizing quality (AQ), coated (on request) |

| Thickness range | Typically 0.5 – 6.0 mm (can be customized) |

| Width range | Typically 500 – 2000 mm |

| Length | 1000 – 8000 mm (or coil for continuous supply) |

| Standards | EN AW-6082, ASTM B209 (or equivalent) |

2. Chemical Composition of 6082

6082 is an Al-Mg-Si alloy with added manganese to improve strength and control grain structure.

Typical Chemical Composition (EN AW-6082)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (each) | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.% | 0.7–1.3 | ≤0.50 | ≤0.10 | 0.4–1.0 | 0.6–1.2 | ≤0.25 | ≤0.20 | ≤0.10 | ≤0.05 | Balance |

Note: Exact composition may vary slightly according to standard, melt practice, and customer-specific requirements, but remains within the specified limits.

3. Mechanical Properties

Mechanical properties depend strongly on temper and thickness. The embossed process minimally impacts bulk mechanical properties but can slightly change surface hardness and rigidity.

Typical Mechanical Properties (Flat 6082 Sheet as Reference)

| Temper | Thickness (mm) | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) |

|---|---|---|---|---|

| O | 1.0–6.0 | 130–180 | 60–110 | 14–22 |

| T4 | 1.0–6.0 | 205–245 | ≥110 | 14–20 |

| T5 | 1.0–6.0 | 240–290 | ≥180 | 8–12 |

| T6 | 1.0–6.0 | 260–310 | ≥240 | 8–12 |

Hardness (Brinell, HBW)

| Temper | HBW (typical) |

|---|---|

| O | 35–50 |

| T4 | 60–80 |

| T5 | 75–95 |

| T6 | 80–100 |

For embossed sheets, actual values are similar to base sheet but can vary slightly depending on final thickness after embossing and process conditions.

4. Physical Properties of 6082

| Property | Typical Value |

|---|---|

| Density | ~2.70 g/cm³ |

| Melting temperature (solidus) | ~555 °C |

| Thermal conductivity | ~170–180 W/m·K |

| Electrical conductivity | ~30–40 % IACS |

| Coefficient of thermal expansion | ~23.4 × 10⁻⁶ /K (20–100 °C) |

| Modulus of elasticity (E) | ~69–72 GPa |

| Poisson’s ratio | ~0.33 |

5. Embossed Surface Types & Functional Features

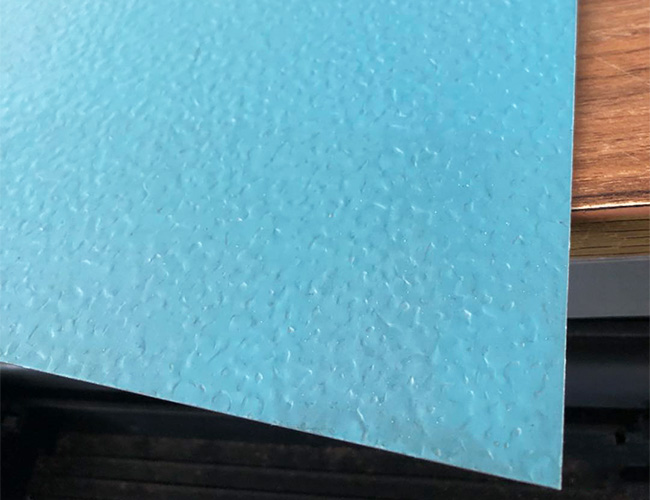

5.1 Common Embossing Patterns

| Pattern Type | Visual Appearance | Typical Applications |

|---|---|---|

| Stucco / Orange Peel | Fine irregular dimples like orange skin | Cladding, insulation jacketing, decorative surfaces |

| Diamond / Five-bar | Raised diamond or bar shape | Anti-slip flooring, steps, walkways |

| Lentil / Bean | Rounded lentil-like protrusions | Vehicle flooring, machine platforms |

| Customized patterns | As per drawing or mold | Branding, specific functional design |

5.2 Main Functional Advantages

| Feature | Benefit |

|---|---|

| Enhanced anti-slip performance | Raised pattern increases friction, safer flooring & steps |

| Improved aesthetics | Textured surface hides minor scratches and dents |

| Reduced glare | Embossing scatters light, reducing reflection and eye fatigue |

| Increased perceived thickness/rigidity | Pattern improves stiffness against bending & denting |

| Easy to clean | Non-stick aluminum surface; smooth edges of patterns help cleaning |

| Noise reduction (in some designs) | Patterns can dampen resonance on panels and covers |

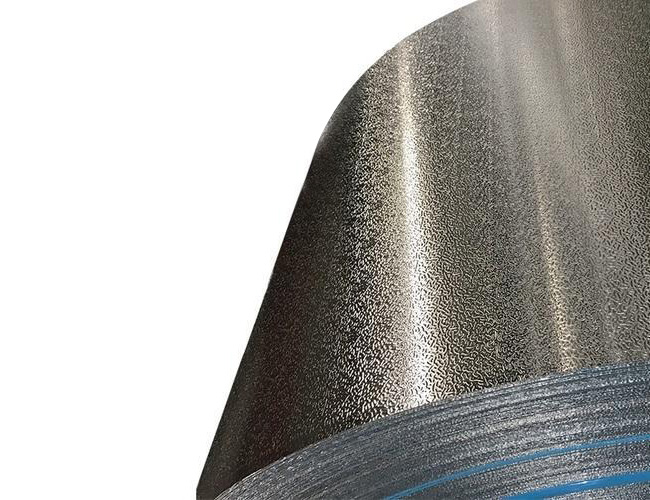

6. Technical Specifications of Embossed 6082 Sheet

6.1 Standard Dimensions & Tolerances

| Parameter | Typical Range/Value |

|---|---|

| Thickness (base) | 0.5 – 6.0 mm |

| Embossed height | Approx. 0.2 – 1.5 mm depending on pattern & thickness |

| Width | 500 – 2000 mm |

| Coil inner diameter | 505 / 508 mm (typical) |

| Coil weight | 1 – 5 tons (customizable) |

| Flatness tolerance | According to EN/ASTM or customer specification |

| Thickness tolerance | As per EN 485 / ASTM B209 or customized |

6.2 Surface Quality

| Parameter | Description |

|---|---|

| Surface finish | Clean, free from heavy rolling marks, bubbles, and major scratches |

| Pattern uniformity | Continuous pattern with consistent height and spacing |

| Edge quality | Mill edge or slit edge as required |

| Surface treatment option | Mill finish, anodizing-quality (for decorative anodizing), coated |

| Protective film | PE/PVC film on one or both sides (optional) |

7. Processing & Fabrication Characteristics

7.1 Workability

| Operation | Performance & Recommendations |

|---|---|

| Bending | Good in O and T4; in T6 use larger bend radius to avoid cracking |

| Forming | Suitable for light to moderate forming; complex forming best in softer tempers (O/T4) |

| Cutting / Shearing | Good; use sharp tools for clean edges; consider pattern orientation |

| Punching | Feasible; allow for embossed geometry while designing punch dies |

| Machining | Good machinability, especially in T6; chips break easily |

| Welding (MIG/TIG) | Generally good weldability; strength in heat-affected zone reduced vs. base material |

7.2 Recommended Minimum Bend Radii (Guide)

(Values refer to bend radius for 90° bends across the rolling direction.)

| Temper | Thickness (mm) | Recommended Inner Radius (× t) |

|---|---|---|

| O | 1.0–3.0 | 0.8–1.0 |

| T4 | 1.0–3.0 | 1.0–1.5 |

| T6 | 1.0–3.0 | 2.0–3.0 |

For embossed sheets, select slightly larger radii than flat sheet due to the patterned surface.

8. Corrosion & Surface Treatment

8.1 Corrosion Resistance

6082 alloy has good general corrosion resistance, especially in atmospheric and industrial environments. For marine or chemically aggressive environments, additional protections are recommended.

| Environment Type | Corrosion Performance |

|---|---|

| Indoor dry | Very good |

| Outdoor (rural) | Very good |

| Outdoor (industrial) | Good, anodizing or coating recommended |

| Marine (salt spray) | Acceptable, anodizing or high-performance coating advised |

8.2 Available Surface Treatments

| Treatment | Purpose/Advantages |

|---|---|

| Anodizing | Enhance corrosion resistance, hard surface, decorative colors possible |

| Powder coating | High durability, color stability, improved weather resistance |

| PVDF coating | Premium outdoor durability, UV & chemical resistance |

| Clear lacquer | Simple anti-fingerprint and surface protection |

Embossed patterns show a richer visual effect after anodizing or coating; light and shadow enhance texture.

9. Main Features of 6082 Embossed Aluminum Sheet

| Category | Features |

|---|---|

| Mechanical | Higher strength than 5052/5754 in similar tempers; good rigidity |

| Weight | Lightweight vs. steel; easy handling and installation |

| Surface | Anti-slip, decorative, low glare, improved impact and scratch hiding |

| Durability | Good corrosion resistance, long service life |

| Processing | Good weldability & machinability; suitable for bending & fabrication |

| Economy | Good cost-to-performance ratio; low maintenance |

10. Typical Applications

10.1 Transportation Industry

| Application Area | Function |

|---|---|

| Truck / trailer flooring | Non-slip surface, reduced weight compared to steel |

| Bus / coach interiors | Step plates, aisle flooring, baggage compartment linings |

| Railway carriages | Interior floors, stair treads, anti-slip passageways |

| Marine decks | Ship gangways, platforms, cabin floors |

| Vehicle toolbox lids | Protective decorative covers, durable in outdoor use |

10.2 Building & Construction

| Application | Purpose |

|---|---|

| Stair treads & ramps | Anti-slip safety surface |

| Walkways & catwalks | Lightweight structures with good load-bearing behavior |

| Facade cladding | Decorative panels, improved stiffness and visual texture |

| Elevator & lobby trims | Impact-resistant panels with a modern metallic look |

| Roof access platforms | Non-slip walkways for maintenance & inspection |

10.3 Industrial Equipment & Facilities

| Application | Function |

|---|---|

| Machine platforms | Safe anti-slip steps and maintenance areas |

| Equipment covers & guards | Protective and easy-to-clean surface |

| Storage racks & shelves | Sturdy yet light panels for industrial environments |

| Insulation jacketing | Stucco finish used to protect insulation on pipes and tanks |

| Workshop flooring | Durable and easy-to-clean floor panels |

10.4 Commercial & Decorative Uses

| Application | Advantages |

|---|---|

| Decorative wall panels | Unique metal texture pattern for retail & public spaces |

| Display stands & kiosks | Visual appeal plus low maintenance |

| Interior design accents | Modern industrial aesthetic (counter fronts, bars, etc.) |

| Protective kick plates | Impact resistance in corridors, doors, loading areas |

11. Comparison with Other Embossed Alloys

| Alloy | Strength (T6) | Corrosion Resistance | Workability/Formability | Typical Use When Embossed |

|---|---|---|---|---|

| 3003 | Low–medium | Very good | Excellent | Insulation jacketing, cladding, decoration |

| 5052 | Medium | Excellent (marine) | Very good | Marine flooring, tanks, vehicle body |

| 6082 | Medium–high | Good | Good | Structural flooring, heavy-duty walkways |

| 6061 | Medium–high | Good | Good | General structural, frames, flooring |

6082 is preferred over 3003/5052 where higher structural strength is required (e.g., vehicle and industrial flooring) while still retaining acceptable corrosion resistance and processability.

12. Ordering Options & Customization

When specifying embossed aluminum sheet 6082, consider the following parameters:

| Parameter | Available Options |

|---|---|

| Alloy & temper | 6082 O/T4/T5/T6/T651 |

| Pattern | Stucco, orange peel, diamond, five-bar, lentil, customized |

| Thickness | Base sheet 0.5–6.0 mm, final thickness after embossing |

| Dimensions | Sheets or coils; customized width and length |

| Surface treatment | Mill finish, anodized, coated (PE, PVDF), lacquer |

| Protective film | Single or double-sided PE/PVC film |

| Standard compliance | EN/ASTM or client-specific technical specifications |

Providing application details (load requirements, environment, fabrication process) helps fine-tune alloy temper, thickness, and surface treatment for optimal performance and cost.

Embossed aluminum sheet 6082 offers a combination of:

- High strength and rigidity for structural and flooring applications

- Anti-slip, low-glare, decorative surface due to embossing patterns

- Good corrosion resistance suitable for transportation, architectural, and industrial use

- Excellent processability: weldable, machinable, and formable with proper temper selection

For customers seeking durable, safe, and visually attractive panels in demanding environments—such as vehicle floors, industrial walkways, and building stair treads—6082 embossed aluminum sheet is a highly reliable and efficient choice.

https://www.aluminumplate.net/a/embossed-aluminum-sheet-6082.html