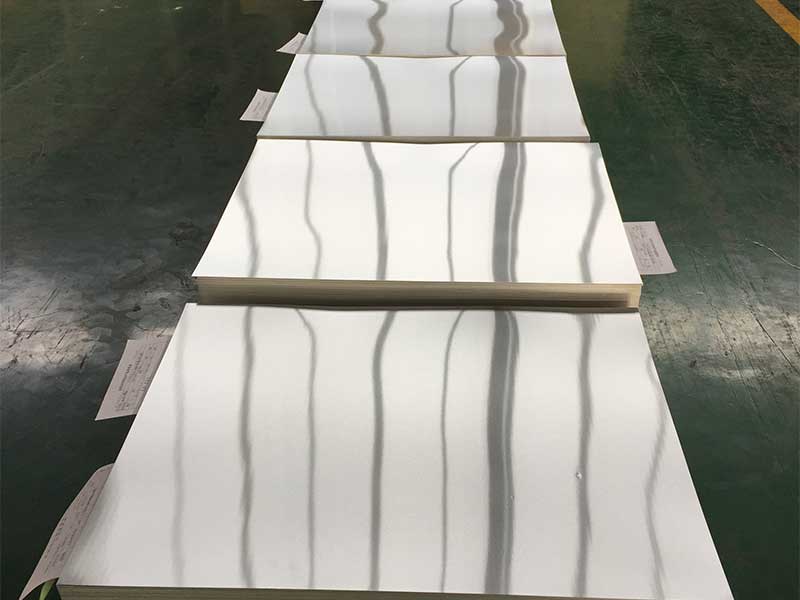

6061 t6 painted aluminum sheets plates

When engineers and buyers specify “6061 T6 painted aluminum sheets plates,” they’re usually thinking in terms of color and corrosion protection. But looking at this material purely as “aluminum with paint” actually underestimates its technical value.

From an engineering standpoint, a painted 6061‑T6 plate is a surface‑engineered structural component: the alloy and temper provide mechanical backbone, while the coating system turns this structural substrate into a functional skin (optical, chemical and protective). it this way leads to better material selection, longer service life, and fewer failures in cutting, forming, or welding.

1. What 6061‑T6 Painted Aluminum Really Is

1.1 Base material: 6061 alloy

6061 is an Al‑Mg‑Si precipitation‑hardening alloy. That means its strength depends on a controlled sequence of solution treatment, quenching and artificial aging, which produces fine Mg₂Si precipitates inside the aluminum matrix.

alloying roles:

- Mg + Si → Mg₂Si: Main strengthening phase (precipitates).

- Cu: Additional strength and response to heat treatment; affects corrosion resistance and fatigue (both positively and negatively).

- Cr: Grain control, improves toughness and resistance to intergranular corrosion.

Typical chemical composition of 6061 (mass %):

| Element | Si | Fe (max) | Cu | Mn (max) | Mg | Cr | Zn (max) | Ti (max) | Others (each) | Others (total) | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| % | 0.40–0.80 | 0.70 | 0.15–0.40 | 0.15 | 0.80–1.20 | 0.04–0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Balance |

(Exact values may vary slightly by standard; this aligns with ASTM B209 / GB/T 3190 for 6061.)

1.2 Temper designation: T6

For 6061, T6 indicates:

- Solution heat treated (typically ~530–550 °C),

- Water quenched, then

- Artificially aged (commonly ~160–180 °C for several hours).

This produces high strength and good stiffness, but:

- Increases springback when bending.

- Reduces formability compared with annealed temper (O) or T4.

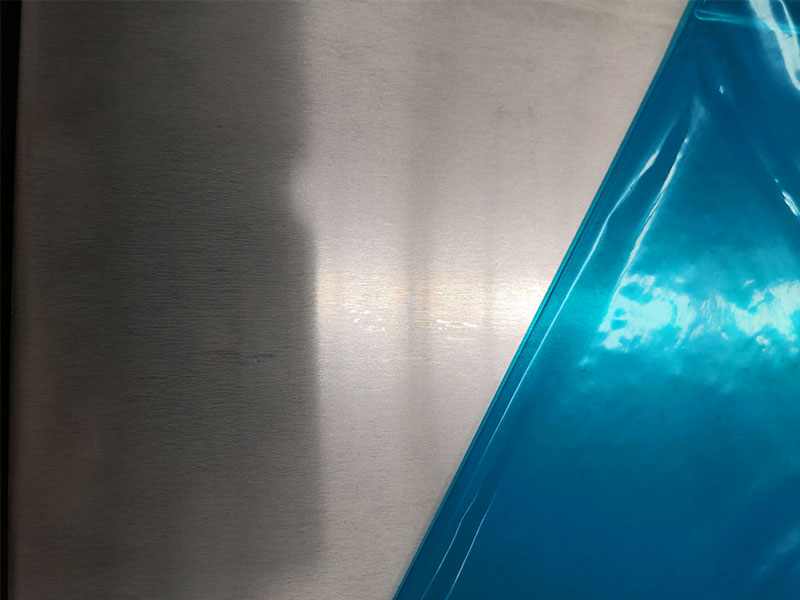

1.3 “Painted” = Coating System, Not Just Color

“Painted” 6061 often means a factory-applied, coil- or sheet-coated system, not simple hand painting. Typical processes:

- Surface preparation

- Alkaline or acid cleaning (remove oil/oxide).

- Conversion coating (chromate or non‑chromate) to improve adhesion and corrosion performance.

- Primer coat

- Epoxy or polyester base; critical for adhesion and anti‑corrosion.

- Top coat

- Polyester (PE) – economical, decent UV resistance.

- Silicone modified polyester (SMP) – better UV resistance and chalking resistance.

- Polyvinylidene fluoride (PVDF / Kynar 500/Hylar 5000)** – premium exterior performance, excellent UV and chemical resistance.

- Curing

- Oven baking to crosslink the coating, achieve specified hardness and gloss.

This yields a functional “outer skin” with properties that do not exist in bare 6061: specific solar reflectivity, color stability, chemical resistance, dirt pickup resistance, etc.

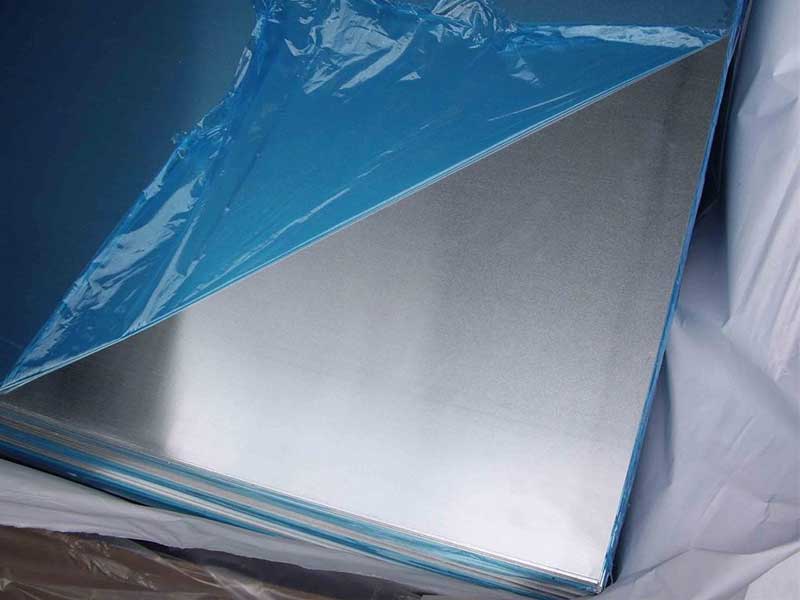

2. Technical Parameters: How These Sheets/Plates Are Typically Supplied

2.1 Dimensions & tolerances (typical industrial ranges)

- Thickness (sheet): ~0.5–3.0 mm

- Thickness (plate): ~3.0–150 mm+ (societal but coatings beyond ~10 mm mostly for structural/architectural panels or machine bases)

- Width: ~600–2500 mm (commonly 1000 / 1220 / 1250 / 1500 mm)

- Length: Cut-to-length: 2000 / 2440 / 2500 / 3000 / 4000 mm, or per drawing.

- Thickness tolerance: per ASTM B209 / EN 485 / GB/T 3880; typical:

- ~±0.03–0.10 mm (thin sheets)

- Increasing tolerance as thickness grows

- Flatness & surface quality: controlled per product standard (e.g., max camber, bow, oil canning)

2.2 Mechanical properties for 6061‑T6 (base alloy, unclad)

Typical minimum values (ASTM B209, metric):

- Tensile strength Rm: ≥ 260 MPa (many mill products are 280–320 MPa range)

- Yield strength Rp0.2: ≥ 240 MPa

- Elongation (L0 = 50 mm): ≥ 8%

- Brinell hardness: ~95 HBW

Note: final painted product’s formability drops slightly after paint bake, and micro‑yielding may change.

2.3 Coating parameters (system-specific)

Representative ranges (coil-coating lines):

- Total coating thickness

- Single-side: 20–30 μm (primer 5–7 μm + top 15–25 μm)

- Two-sided: might be, e.g., 25 μm face / 5–10 μm back (service coat)

- Gloss:

- Matte: 10–30 GU (at 60°)

- Medium: 30–60 GU

- High: 70+ GU

- Pencil hardness: usually HB–2H for architectural PE / PVDF

- Adhesion (cross‑hatch): Class 0–1 (no or few squares removed)

- Impact resistance: 5–10 J (no cracking or peeling), per test method (e.g., ISO 6272)

3. Standards & Specifications That Commonly Apply

Painted 6061‑T6 sheets/plates must simultaneously satisfy metal, coating, and often building/mechanical standards. Examples:

3.1 Base metal standards

- ASTM B209 – Aluminum and Aluminum-Alloy Sheet and Plate

- EN 485 / EN 573 – Wrought aluminum sheet/plate & chemical composition

- GB/T 3880 / GB/T 3190 – Chinese equivalents for sheets/plates & compositions

These control: chemical composition, mechanical properties, dimensional tolerances, and metallurgical temper.

3.2 Coating & performance standards

- AAMA 2603 / 2604 / 2605 – Performance requirements for architectural coatings (mostly extrusion but often referenced for coils)

- 2603: standard exterior

- 2604: high-performance

- 2605: superior PVDF façade grade

- ISO 2810 – Natural weathering of coatings

- ISO 6272 / ASTM D2794 – Impact resistance (rapid‑deformation test)

- ISO 2409 / ASTM D3359 – Cross‑cut adhesion test

- ISO 9227 / ASTM B117 – Neutral salt spray corrosion testing

When specifying 6061‑T6 painted plate for demanding external use, tying your requirement to, say, “PVDF system with AAMA 2605-level performance” clarifies expectations related to chalking, color change, fade and blistering.

Thinking like a designer or systems engineer, there are three interacting layers of performance:

- Structural core (6061‑T6)

– Strength, stiffness, machinability, weldability. - Interfacial zone (pretreatment + primer)

– Adhesion, galvanic barrier, underfilm corrosion resistance. - Functional outer skin (top coat)

– UV resistance, visual effect, cleanability, chemical shield.

4.1 Use cases that favor painted over anodized

While 6061 anodizes well, painted surfaces are often chosen when:

- Tight color repeatability & customization: RAL / Pantone / corporate colors, gloss levels, special effects (metallic, textured).

- High hiding power over welds or machining marks: paint can visually uniformize surfaces with varied microstructure.

- Multi-function surfaces:

- Anti‑graffiti, anti‑fingerprint finishes.

- High IR reflectance (cool roof / enclosure panels).

- Food‑compatible or specific chemical‑resistant linings (with certified coatings).

- Repairable surfaces: local paint touch‑ups are easier than re‑anodizing.

4.2 Thermal & optical behavior

Through pigments and binder choice, the coated layer can define:

- Solar reflectance / thermal emissivity – important in façade cladding, vehicle roofs, electronics enclosures.

- Glare control – matte finishes in transportation cabins, instrument housings.

- Infrared signature – in some defense and high‑tech applications; specially formulated paint over 6061 can tune IR reflectance and emissivity.

Paint transforms 6061‑T6 into an optical component, not just a colored metal.

5. Mechanical Behavior of 6061‑T6 under Paint: What Changes?

The base mechanical properties come from the T6 temper, but painting slightly alters the system behavior:

- Paint bake effect

- If the material is supplied T4 then coil‑coated with a bake step, it can “age” toward T6 (bake‑hardening).

- For T6 plate that’s later painted and cured again at elevated temperature, over‑aging is possible if cycles are not controlled (loss in yield strength).

- Surface micro-cracking upon forming

- Bending painted 6061‑T6 beyond certain radii may show paint micro‑cracks due to the high substrate strength and limited plasticity.

- Friction & tooling interaction

- The paint changes friction coefficients during forming or stacking; this helps batching and scratch resistance but may demand revised die design.

For demanding forms, many engineers choose either:

- Form first in a softer temper (6061‑T4), then paint, arguably yielding better coated edge quality; or

- Use thicker bend radii and avoid post‑forming of fully hard 6061‑T6 painted product.

6. Typical Functional Applications by Sector

6.1 Architecture & building envelope

Cladding, soffits, parapet panels, column covers, façade cassettes

Why 6061‑T6 painted instead of 3003 or 5052?

- Need for structural role: 6061‑T6 has higher yield strength, can span longer distances with thinner gauges when carefully designed.

- Precision machined mounting brackets and façade inserts use the same 6061 stock, simplifying systems across structure and cladding.

- Painted PVDF 6061 with appropriate pretreatment provides robust corrosion performance when detailed correctly.

6.2 Transportation & vehicle bodies

Used for:

- Truck bodies, aerial lift platforms, flatbed flooring covers (top coats designed for slip resistance).

- Trailers and recreational vehicles external panels.

- Rail and bus interior/exterior fascia.

6061‑T6 benefits:

- Structural reliability under dynamic loads, better fatigue behavior than some non‑heat‑treatable alloys.

- Coating can be tuned ultravioletly stable and graffiti-resistant (especially important in rail).

6.3 Marine environments

Although 5xxx alloys (e.g., 5083) are more common for immersed conditions, 6061‑T6 painted finds use in:

- Superstructures, deck housings, mast covers, gangways.

- Machinery housings above waterline.

The paint acts as primary barrier against chloride attack; the 6061 structurally carries loads like mast mounts, radar supports, deck equipment racks.

Design note: edge preparation and sealants are crucial, especially near welded or bolted joints, to prevent crevice corrosion.

6.4 Equipment housings & enclosures

Common in:

- Electrical cabinets, generator housings.

- Industrial HVAC covers, pump/motor enclosures.

- Precision machine guards / safety shields ( stronger sections with minimal deflection).

Here, choosing 6061‑T6 allows you to:

Machine complex cutouts, tapped holes, rails directly in plate.

Maintain flatness and dimensional stability.

A properly specified paint system also adds:Chemical resistance to industrial atmospheres (SO₂, Cl⁻, oil fumes).

Custom color coding for equipment zones/safety.

6.5 Aerospace & high‑tech structures

6061 doesn’t carry critical airframe primary structures like some 2xxx/7xxx alloys but is widely used as:

- Avionics mounting plates, brackets, electronic racks.

- Ground support frames/cradles and external covers.

Painting here serves functionally:

- Color coding and labeling (maintainable systems).

- Reflective / low‑outgassing surface depending on aerospace requirements.

- Reduced corrosion under condensation or fluid spills.

7. Design & Selection Guidelines from a Practical Viewpoint

Thinking from a “system integration” perspective, use these checkpoints when specifying:

7.1 Choose temper and forming route carefully

- If significant bending / deep forming is needed:

- Prefer forming in 6061‑O or T4, then hardening (and/or paint baking) afterward.

- Or apply larger inside radii for T6 (often ≥ 3–4× thickness, or as per bend data/die trials).

- If parts are largely flat or simply profiled, T6 with pre‑paint is ideal – dimensional stability and large flat, decorative/performance surfaces.

7.2 Coating system vs. environment

Match top coat to exposure:

- Indoor, non-UV critical: standard polyester may be sufficient.

- Normal outdoor façade, 10–15 year life: high‑durability polyester or SMP.

- Harsh UV/coastal/industrial: PVDF-based with a high fluoropolymer content, conversion coat chosen with care (often non‑chromate in jurisdictions with Cr(VI) restrictions) plus sealed cut edges.

Tie the spec to recognized performance schemes (e.g., “equivalent to AAMA 2604/2605 for chalk, fade, adhesion and film integrity”).

7.3 Machining, welding, and post‑processing

- Machining: 6061‑T6 is excellent for CNC routing and drilling. For painted plate, precise fixturing and compressive support reduce edge paint chipping.

- Welding: desirable to weld on bare 6061 and paint after. If welding Must be done on pre-painted stock, grinding back the coating at the joint and afterward carefully restoring primer/top coat is critical.

- Edge limitation: sheared edges are points of accelerated corrosion if left bare. Best practice: oppose sharp edges using deburring, then prime/paint or use edge sealers in exteriors.

| Property Type | Parameter | Typical Value / Range | Notes |

|---|---|---|---|

| Substrate | Alloy designation | 6061 | Al‑Mg‑Si, heat-treatable |

| Temper | T6 | Solution‑heat‑treated + aged | |

| Tensile strength | 260–320 MPa | Dep. on product/producer | |

| Yield strength | ≥ 240 MPa | ASTM B209 typical minimum | |

| Elongation (50 mm) | 8–12 % | Thicker plates typically show more | |

| Brinell hardness | ~95 HBW | Macro hardness | |

| Coating | System type | PE / SMP / PVDF | Chosen per environment |

| Coating thickness (top) | 15–25 μm | Face side; primer 5–7 μm | |

| Pencil hardness | HB–2H | Depends on paint chemistry | |

| Gloss (60°) | 10–80 GU | Matte to high gloss | |

| Color tolerance | ΔE ≤ 2–3 (batch‑to‑batch) | High‑end coil coating control | |

| Adhesion (crosshatch) | Class 0–1 | No flaking on scribed area | |

| Salt spray resistance | 500–2000 h (no blisters/creep limits) | As per ISO 9227 requirements | |

| UV/clouding resistance | Meets AAMA 2603–2605 level targets | According to selected standard | |

| Integration | Min. bend radius (T6 painted) | ≈ 3–4× t upward | Check lab tests; paint cracking possible below |

| Thermal stability (cure) | 200–260 °C* | Avoid over‑aging T6 in long cycles |

*Cure times and temperatures depend on paint manufacturer; integrated overlife cyles need to consider potential over‑aging of T6 if multiple bakes/heat exposers are planned.

9. A Distinctive Way to Specify 6061‑T6 Painted Plate

Instead of simply asking for “6061 T6 painted sheets,” a functional specification might read:

6061‑T6 aluminum sheet/plate according to ASTM B209 (or EN 485 / GB/T 3880), thickness X mm, chemically pre‑treated (chromium‑free conversion or equiv.), factory pre‑coated via coil/sheet coating with a system, nominal top‑coat film thickness ≥ 20 μm, back‑coat 5–10 μm, color RAL XXXX, gloss YY±5 GU, performance meeting or exceeding . Paint line curing shall prevent significant loss of T6 strength (yield loss ≤ N% vs standard 6061‑T6).

This specification ties mechanical, chemical, and optical requirements directly together, turning “6061‑T6 painted aluminum sheet/plate” into a controllable engineering solution rather than just a commodity.

6061‑T6 painted aluminum sheets and plates are not merely pazel plates with color. They are high-strength, heat-treated aluminum substrates enhanced with a precision-engineered protective and functional coating system. the interplay between alloy chemistry, Temper conditions, coating chemistry, processing heat cycles, and end-use environment allows you to design better components and specify material that will actually perform as intended for decades.

https://www.aluminumplate.net/a/6061-t6-painted-aluminum-sheets-plates.html