5083 h36 aluminum plate

5083 H36 aluminum plate is a high‑strength, corrosion‑resistant marine‑grade aluminum plate, strain‑hardened and partially stabilized by low‑temperature heat (“H36” temper). It combines excellent seawater corrosion resistance with good weldability and moderate to high strength, making it widely used in shipbuilding, vehicle bodies, pressure vessels, and structural components exposed to aggressive environments.

Note: Exact values may vary slightly between standards (ASTM, EN, GB, etc.) and manufacturers. The data below are typical ranges for reference.

1.1 Alloy System & Temper

- Alloy designation: 5083

- Series: 5xxx series, Al–Mg based alloy

- Main alloying element: Magnesium (Mg) ~4.0–4.9%

- Temper code: H36 (strain-hardened and partially stabilized; tensile strength level between H34 and H38)

- Typical standards: ASTM B209, EN 485/573, GB/T 3880 et al.

1.2 Product Features

- High strength in non‑heat‑treatable alloys

- Outstanding corrosion resistance, especially in seawater and marine atmospheres

- Good weldability (MIG/TIG) with limited conductivity loss in HAZ

- Good fatigue resistance for dynamic loads

- Non-magnetic, excellent formability (moderate bending, cold forming)

- Good compatibility with protective coatings and anodizing (decorative and protective)

2. Chemical Composition of 5083 Aluminum Alloy

2.1 Typical Chemical Composition (Wt.%)

| Element | Minimum (%) | Maximum (%) | Function / Effect |

|---|---|---|---|

| Si | — | 0.40 | Controls melting–solidification behaviour, improves castability |

| Fe | — | 0.40 | Impurity; excessive Fe may affect toughness & corrosion |

| Cu | — | 0.10 | Kept very low to ensure top-level corrosion resistance |

| Mn | 0.40 | 1.0 | Strengthens alloy, improves corrosion & resistance to SCC |

| Mg | 4.0 | 4.9 | Main strengthening element; improves strength & work-hardening |

| Cr | 0.05 | 0.25 | Grain refinement, improves toughness & stress corrosion |

| Zn | — | 0.25 | Kept low to minimize stress corrosion susceptibility |

| Ti | — | 0.15 | Grain refiner during casting; improves structure uniformity |

| Others (each) | — | 0.05 | Unspecified trace elements |

| Others (total) | — | 0.15 | Total of all traces |

| Al | Remainder | Remainder | Basis of alloy |

3. Mechanical & Physical Properties (5083 H36)

The H36 temper corresponds to a strain-hardened condition with a strength level slightly higher than H34 (H34 < H36 < H38). It is used when a balance between high strength and certain formability is required.

3.1 Mechanical Properties (Typical, Room Temperature)

| Property | Typical Value (H36) | Remarks / Test Direction |

|---|---|---|

| Tensile strength, σUTS | 305–365 MPa | Longitudinal, standard thickness plates |

| Yield strength, σ0.2 | 215–260 MPa | 0.2% offset, longitudinal |

| Elongation (A50) | 10–16 % | Depends on thickness & direction |

| Modulus of elasticity, E | ~69 GPa | Practically independent of temper |

| Shear strength (typical) | ~195 MPa | Approximate reference |

| Poisson’s ratio | ~0.33 | |

| Hardness (Brinell HBW) | ~95–110 HB | 10 mm ball / 500 kgf (typical reference) |

| Fatigue strength (R = −1) | ~90–100 MPa | After many millions of cycles, typical |

3.2 Physical Properties

| Property | Typical Value | Notes |

|---|---|---|

| Density | 2.65–2.68 g/cm³ | Slightly depends on Mg content |

| Melting range | 570–640 °C | Solidus–liquidus |

| Thermal conductivity | 117–150 W/(m·K) | At ~25 °C |

| Electrical conductivity | ~28–32 % IACS | Lower than pure Al due to Mg |

| Coefficient of thermal expansion | 23–24 × 10⁻⁶ /K (20–100 °C) | Typical for 5xxx series |

| Specific heat capacity | ~0.90 J/(g·K) | |

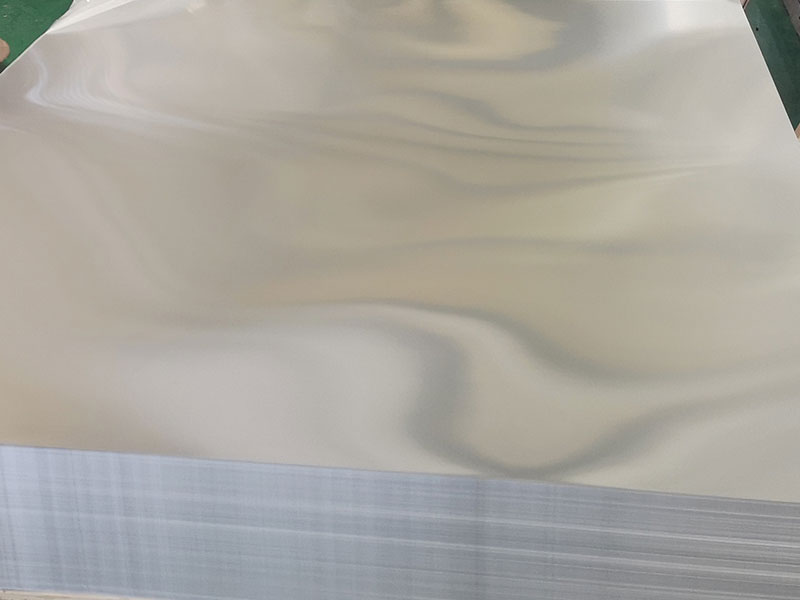

| Emissivity (as-rolled surface) | 0.15–0.30 | Depends on surface finish |

4. Technical Specifications – Products, Dimensions & Tolerances

4.1 Available Product Forms (Typical)

| Item | Specification Range (Typical) |

|---|---|

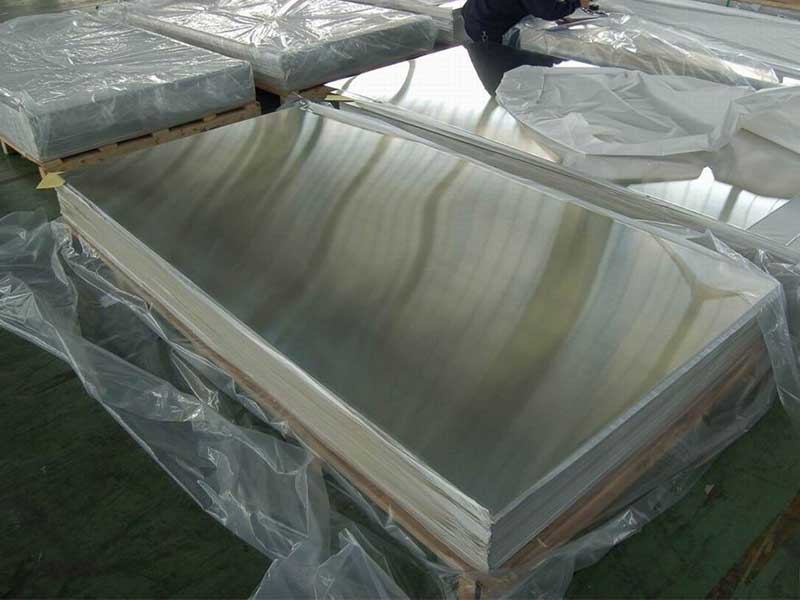

| Production form | Plate, sheet |

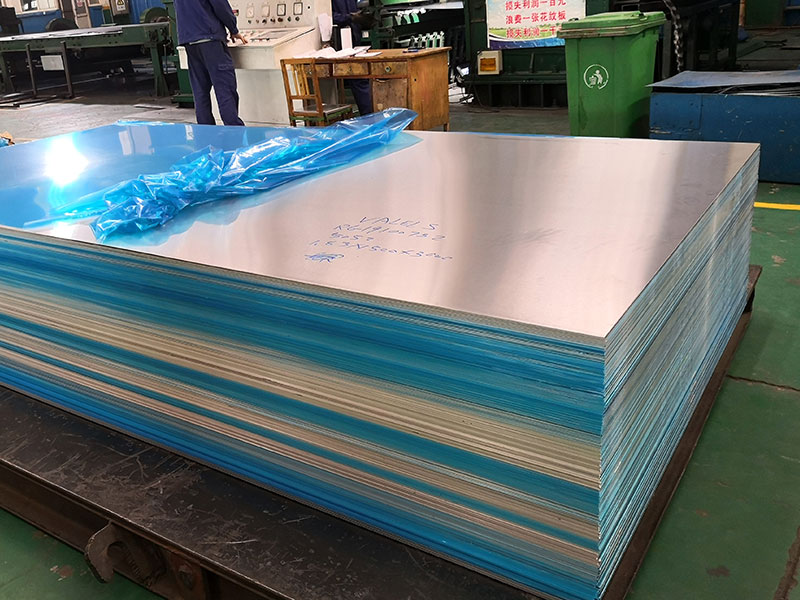

| Manufacturing process | Hot-rolled, cold-rolled, followed by H36 temper |

| Thickness range | ~1.5–60 mm (customized wider range available) |

| Width range | 800–2600 mm (wider plates by agreement) |

| Length range | 2000–12000 mm (cut-to-length / coil-to-plate) |

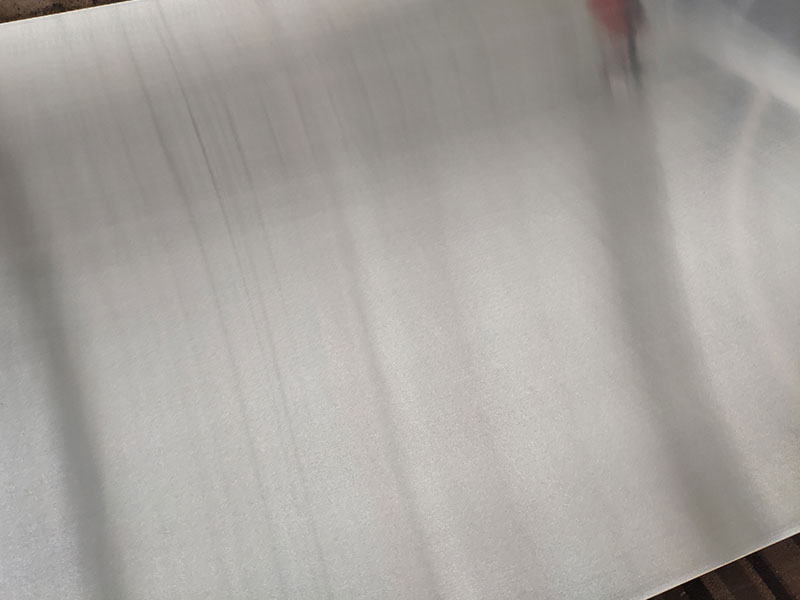

| Surface condition | Mill finish, shot-blasted, diamond pattern, brushed, anodized |

| Edge condition | Mill edge, trimmed edge, chamfering optional |

| Standard formats | 4×8 ft, 5×10 ft, customized |

Exact dimensional capabilities depend on each production line and mill.

4.2 Dimensional Tolerances (Guide)

| Parameter | Typical Tolerance (depends on standards & thickness) |

|---|---|

| Thickness tolerance | ±0.08–0.30 mm (thin to thick plates) |

| Width tolerance | ±2.0–3.0 mm |

| Length tolerance | ±3.0–5.0 mm |

| Flatness | ≤5–10 mm/m (standard) or tighter by agreement |

| Squareness | ≤2–3 mm/1000 mm |

5. Temper Characteristics – What H36 Means for 5083

5.1 Definition of H36 Temper

- H – Strain-hardened (work-hardened, cold‑rolled)

- 3 – Subcategory: strain-hardened and then partially annealed to adjust properties

- 6 – Strength level: specific range of tensile strength/work-hardening grade

Compared with related tempers:

| Temper | Processing | Relative Strength | Relative Formability | Typical Application |

|---|---|---|---|---|

| O | Fully annealed | Lowest | Best | Deep drawing, intensive forming |

| H111 | Slight strain‑hardened | Low–medium | Good | Formed structures, moderate strength |

| H116 | Special marine temper (strain-hardened + stabilized) | High (close H32) | Medium | Marine plates requiring SCC resistance |

| H32 | Strain-hardened & stabilized | Medium–high | Medium | General structural / marine use |

| H36 | Strain-hardened & stabilized (higher work hardening) | Higher than H34 | Medium–low | Heavier loading, still some formability |

| H38 | Strain-hardened & stabilized (maximum work hardening) | Highest (in series) | Lower | Where maximum strength is critical |

5083 H36 is selected when you want a strength level between H34 and H38 with controlled toughness and still usable forming/welding performance.

6. Performance Characteristics

6.1 Corrosion & Marine Performance

5083 is recognized as one of the best corrosion‑resistant aluminum alloys for seawater and chloride environments.

advantages:

- Excellent resistance to:

- Seawater corrosion, marine atmosphere

- Industrial atmosphere with chloride exposure

- Freshwater, many neutral/weakly alkaline solutions

- Stress-corrosion cracking (SCC) resistance greatly superior to 2xxx and 7xxx alloys in similar marine service.

- Good performance in crevice and pitting corrosion with proper design and protective coating.

| Environment / Medium | Performance Level | Notes |

|---|---|---|

| Seawater (static/low speed) | Excellent | Minimal general corrosion with proper design |

| Marine atmosphere | Excellent | Often used without heavy painting systems |

| Fresh water | Excellent | Common for tanks & potable water services |

| Many petroleum products | Excellent | Crude oil, diesel, marine fuels, etc. |

| Mild industrial atmosphere (SO₂, NOx low) | Very good | Stable with occasional maintenance |

| Highly acidic solutions (strong acids) | Poor–Fair | Not recommended without lining/protection |

| Highly alkaline solutions (~pH > 10) | Fair | Possible caustic attack |

6.2 Weldability & Fabrication

- Suitable welding processes: MIG, TIG, friction stir welding (FSW), resistance spot welding (limited thickness).

- Filler wires: ER5183, ER5356, ER5556, etc. chosen to optimize seam strength and corrosion properties.

- Weldability characteristics:

- No propensity to hot‑cracking if weld metal and procedure are correctly selected.

- Some strength loss in Heat Affected Zone (HAZ) compared to base H36 material – typical for work-hardened non‑heat‑treatable alloys. Structures should be designed considering weld strengths.

Formability:

- Suitable for:

- Roll forming, press braking

- Moderate cold bending and drawing

- For more severe forming operations, softer tempers (O / H111 / H32) may be preferred, then H36 for less‑formed regions or secondary reinforcing plates.

6.3 Fatigue & Impact Performance

- 5xxx series, including 5083, has favorable fatigue behavior in marine and transportation structures:

- High damping capacity relative to steels, beneficial for vibration control.

- Stable under cyclic loading; https://www.aluminumplate.net should follow fatigue design practice.

Fatigue strength is condition and detail‑class‑dependent; typical endurance limit is in the 90–100 MPa range (un-notched lab coupons), lower for welded joints, consistent with classification society rules.

7. Typical Applications of 5083 H36 Aluminum Plate

Because of its combination of high strength, low weight, corrosion resistance, and weldability, 5083 H36 is widely used in:

7.1 Marine & Offshore

| Component / Area | Reason for Using 5083 H36 |

|---|---|

| Hull side & bottom plating | High strength-to-weight, seawater resistance |

| Superstructure & decks | Low weight, corrosion resistance, ease of welding |

| Bulkheads & frames | Structural stiffness, IBS/alloy compatibility |

| Shipboard tanks (ballast, fuel) | Corrosion resistance to water & fuel |

| Fast ferries & work boats | Lighter hulls → higher speed & payload |

| Offshore platform modules | Lower maintenance vs. carbon steel in splash zone |

7.2 Transportation (Land & Rail)

| Application | Benefits |

|---|---|

| Truck & trailer bodies | Corrosion resistance, weight savings |

| Tipper bodies & side walls | High impact resistance, stiffness |

| Container roofs & side panels | Weight reduction → improved payload and fuel economy |

| Bus & coach structural components | Lower vehicle mass, good crash / energy absorption |

| Railcars, metro car shells | Good fatigue & corrosion combined with weldability |

7.3 Pressure Vessels & Storage Tanks

| Application | Features of 5083 H36 That Matter |

|---|---|

| LPG & LNG thermal insulation panels | Good low-temp performance, corrosion resistance |

| Cryogenic/non-cryogenic storage | Good fracture toughness at low temperatures |

| Industrial liquid tanks | Resistance to freshwater and many chemicals |

7.4 General Structural & Industrial Uses

- Structural platforms in chemical plants

- Walkways, bridge decks, stair components in corrosive environments

- Conductive yet durable components in electrical/utility installations

- Architectural exterior panels in coastal zones

8. Advantages & Customer Benefits

8.1 Strength-to-Weight & Design Optimization

Compared with carbon steel:

| Property | 5083 H36 Aluminum | Carbon Steel (Typical) | Effect on Design |

|---|---|---|---|

| Density | ~2.65 g/cm³ | ~7.85 g/cm³ | ~65% lighter for equal volume |

| Tensile strength (indicative) | ~305–365 MPa | ~400–500 MPa | Similar range but much lower weight |

| Corrosion resistance in seawater | Excellent | Needs coating / alloys | Less painting & maintenance |

This translates to:

- Higher payload / passenger capacity

- Lower fuel consumption or energy use

- Improved acceleration and maneuverability (vehicles & ships)

8.2 Operational Cost & Life-Cycle Benefits

- Lower maintenance expenditure — reduced need for heavy coating systems beyond localized protection and markings.

- Longer service life in marine/industrial environments due to slower corrosion metal loss.

- Enhanced recyclability (near 100%) with high residual value at end of life.

8.3 Safety & Reliability

- Non-sparking and non-magnetic

- Good impact toughness even at low temperatures (arctic and cryogenic adjacencies)

- Reliable fatigue performance with proper structural design and weld quality

9. Processing, Cutting, and Surface Treatment

9.1 Cutting & Machining

| Method | Suitability / Notes |

|---|---|

| Shearing | Good for thin plates, use sharp blades |

| Saw cutting | Suitable for medium and thick plates |

| Plasma cutting | Efficient for thick plates, some HAZ softening |

| Laser cutting | Good dimensional precision for thin to mid plates |

| Waterjet cutting | No thermal effect, best for high‑precision edges |

| Drilling/machining | Good machinability; use appropriate lubricants |

9.2 Forming & Bending

- Use larger bend radii than softer tempers; trial bends recommended.

- For tight bends, orient bend line along rolling direction where possible.

- Complex forming may use staged bending, localized annealing, or forming in softer temper then re‑cold working peripheral areas.

9.3 Surface Treatments

| Treatment | Purpose |

|---|---|

| Anodizing | Improve corrosion protection & aesthetic |

| Painting / coating | Enhanced barrier protection & appearance |

| Shot blasting | Cleaning & surface preparation |

| Polishing / brushing | Decorative finishes, improved cleanliness |

Proper pre‑treatment (degreasing, etching, conversion coating) enhances paint or adhesive bond durability.

| Category | Data / Values (Typical) |

|---|---|

| Alloy / temper | 5083 / H36 |

| Alloy type | Al–Mg, non‑heat‑treatable marine alloy |

| Mg content | 4.0–4.9 % |

| Temper description | Strain-hardened & partially stabilized |

| Tensile strength | 305–365 MPa |

| Yield strength | 215–260 MPa |

| Elongation | 10–16 % |

| Density | 2.65–2.68 g/cm³ |

| Corrosion resistance | Excellent in seawater & marine atmosphere |

| Weldability | Excellent (MIG/TIG suitable) |

| Operating temperature range | Approx. −50 °C to +80 °C (long-term structural service) |

| Main applications | Marine hulls, decks, vehicle bodies, tanks, structures |

11. Selection Guidance – When to Choose 5083 H36

Choose 5083 H36 aluminum plate when:

- Your structure operates in marine, coastal, or other highly corrosive environments.

- You require a non‑heat‑treatable alloy with higher strength than O / H111 / H32, preserving reasonable formability.

- Continuous welding and field assembly are necessary, with a strong demand for structural integrity of welds.

- Weight reduction is a priority: ship weight, vehicle weight, transport costs, or handling loads.

- Long service life with minimized maintenance is important.

If more severe forming is expected, use a softer temper (e.g., O or H111) and apply H36 primarily in sections demanding strength and less severe forming.

https://www.aluminumplate.net/a/5083-h36-aluminum-plate.html