Marine aluminum plate 5005,5052 color coated

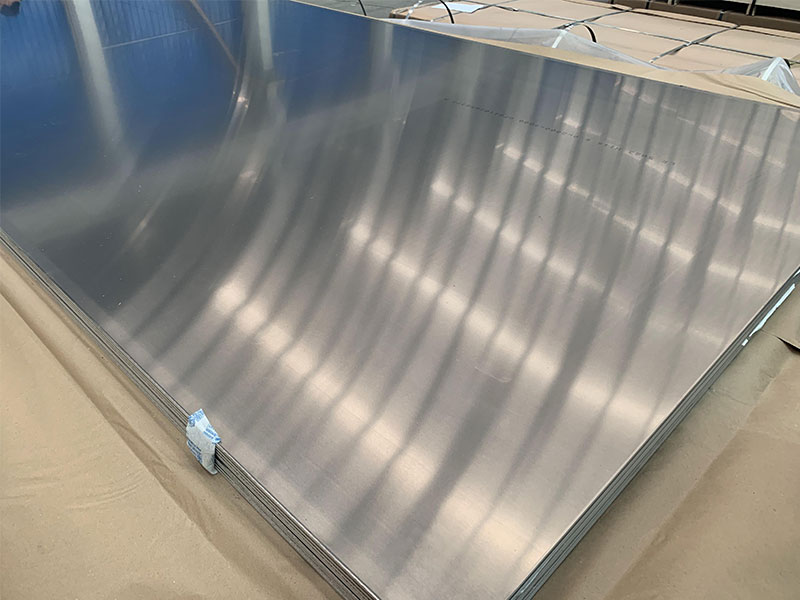

Marine aluminum plates have become vital materials in various marine applications due to their excellent corrosion resistance, lightweight nature, and durability. Among these, the 5005 and 5052 alloys stand out, especially when color-coated for enhanced aesthetic appeal and protection. This guide provides an in-depth of marine aluminum plates of the 5005 and 5052 alloys, highlighting their features, applications, and technical specifications.

Features

Corrosion Resistance: The chemical composition of 5005 and 5052 alloys provides exceptional resistance against seawater and marine environments.

Lightweight: Aluminum has a low density, making these plates easier to handle and install without sacrificing strength.

Aesthetic Qualities: Color coating adds to the visual appeal while providing an additional layer of protection against environmental factors.

Versatile Applications: Ideal for a variety of marine applications including vessels, construction, and offshore facilities.

High Strength-to-Weight Ratio: Both alloys maintain strength properties necessary for structural integrity while being lightweight.

Applications

Marine aluminum plates 5005 and 5052 color-coated are commonly used in:

- Shipbuilding and Repair

- Marine Equipment Manufacture

- Heat Exchangers

- Building Facades

- Recreational Vehicle Construction

- Pleasure Craft Components

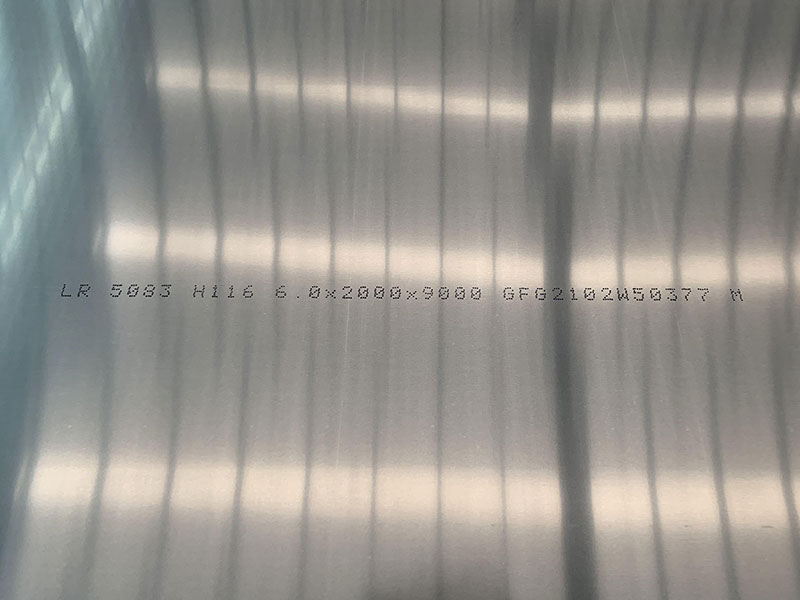

Technical Specifications

Chemical Composition

The following table details the chemical properties of the 5005 and 5052 alloys:

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Others (Al, etc.) (%) |

|---|---|---|---|---|---|---|---|---|

| 5005 | 0.4-0.8 | 0.2 | 0.2 | 0.10-0.5 | 0.2-0.6 | 0.1 | 0.1 | Balance (Al) |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1-0.5 | 2.2-2.8 | 0.15-0.35 | 0.25 | Balance (Al) |

Performance Parameters

The subsequent table summarizes the significant technical properties of these alloys:

| Property | Aluminium Alloy 5005 | Aluminium Alloy 5052 |

|---|---|---|

| Tensile Strength (MPa) | 210-260 | 260-320 |

| Yield Strength (MPa) | 160-230 | 210-260 |

| Elongation (%) | 16-22 | 12-20 |

| Hardness (HB) | 60–90 | 70-100 |

| Density (g/cm³) | 2.66 | 2.68 |

| Heat Treatment | H34, H112, H32 | H34, H112, H32 |

Alloy Tempering Conditions

| Alloy | Temper | Annealing Temperature | Pre-heat Closure Degree | Service Temperature |

|---|---|---|---|---|

| 5005 | H32 | 215-265°C (419-500°F) | Not required | Up to 65°C (149°F) |

| 5052 | H32 | 160-260°C (320-500°F) | Not required | Up to 65°C (149°F) |

takeaways for SEO:

- Comprised of specialized aluminum alloys 5005 and 5052.

- Focused on marine applications including shipbuilding and equipment manufacture.

- Unique combination of lightweight, corrosion resistance, and decorative appeal.

https://www.aluminumplate.net/a/marine-aluminum-plate-50055052-color-coated.html