Pattern aluminum plate 1060

In an era where aesthetics and functionality often go hand in hand, the pattern aluminum plate 1060 surfaces as a prime example of these harmonious qualities. Delving into this material reveals not only its technical attributes but also its diverse applications and aesthetic appeals, catering to a wide range of industries.

Aluminum Alloy 1060

Before we dive into the specifics of patterned versions, it is essential to grasp what makes 1060 aluminum exceptional. Classified as a commercially pure aluminum alloy, 1060 consists of at least 99.6% aluminum. Its purity contributes to its outstanding properties, such as high corrosion resistance, excellent thermal and electrical conductivity, and adaptability in both form and fabrication. In terms of implementation standards, the alloy adheres to ASTM B221 for extrusions, ASTM B679 for plates, and various ISO standards reflecting its global acceptance and consistency in quality.

Characteristics and Benefits of Pattern Aluminum Plate 1060

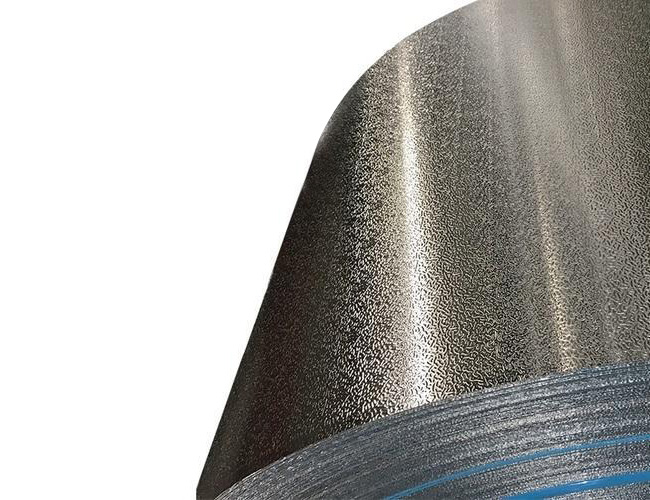

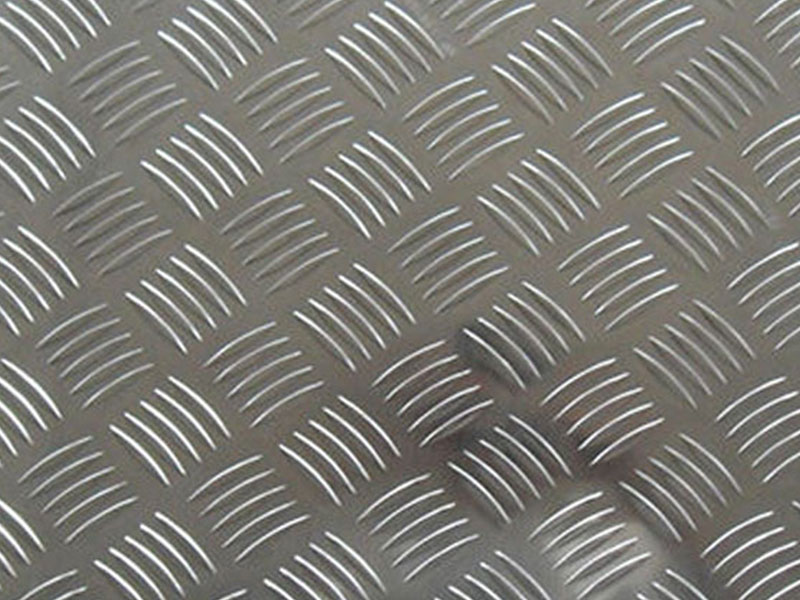

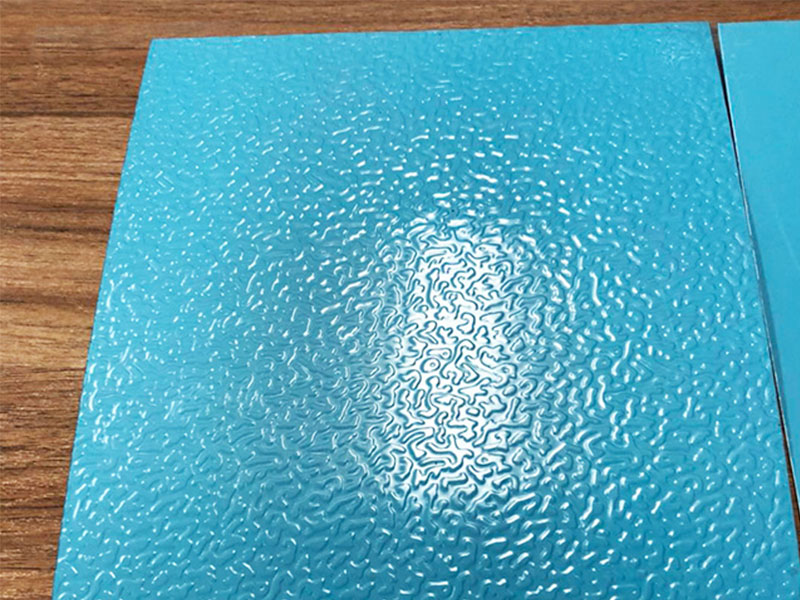

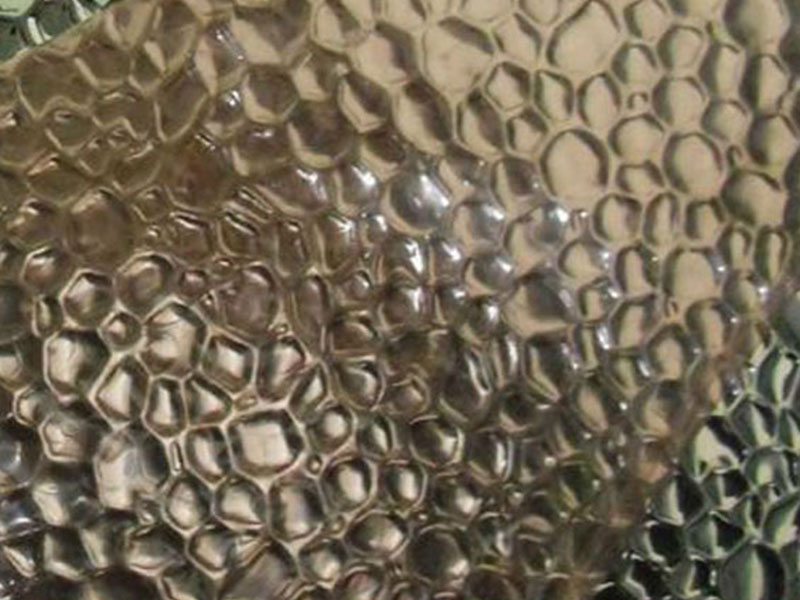

Texture and Aesthetic Appeal: The patterned surface not only enhances its visual appeal but also aids in practical functions by improving grip and traction. Whether used in flooring, cladding, or decorative applications, the texture offers a visually engaging interplay of light and shadow.

Enhanced Durability: The unique surface treatment of pattern aluminum often contributes an additional layer of durability to the substrate aluminum. The patterns increase rigidity and strength, providing further resistance against dents and impact without compromising weight—a crucial factor in so many applications.

Weight Advantage: Weighing significantly less than other metals with comparable strength, aluminum 1060 is a favorable choice in industries such as transportation, where weight savings equate to fuel efficiency and reduced costs.

Chemical Properties: The chemical composition of 1060, primarily composing of aluminum with minuscule amounts of silicon, iron, copper, and magnesium, positions it as highly resistant to oxidation. A surface finish can even enhance this property, making it suitable for outdoor applications where exposure to the elements is imminent.

Practical Implementations of Pattern Aluminum Plate 1060

The pattern aluminum plate 1060 isn’t just a static product—it comes alive in various forms, developing a narrative unique to each application.

1. Architectural Designs: The allure of this material has made it a popular choice for interior and exterior décor in modern architecture. From façade treatments on commercial buildings to accent panels in living spaces, the luster and texture of patterned plates create a striking presence.

2. Vehicle Manufacturing: In automotive and aeronautics, where every gram of weight saved enhances performance, engraved or textured aluminum proves vital for non-structural components where visual appeal can meet resilience, such as door panels or truck bed liners.

3. Refrigeration and Heat Exchangers: Due to its superb thermal conductivity, patterned aluminum materials serve as effective components in HVAC equipment, providing not just functional benefits but contributing efficiently to energy-saving designs.

4. Flooring Options: The anti-slip properties of textured plates are often called into service in both industrial and public sectors, significantly enhancing the safety aspect when used in high-traffic geographies. The ease of cleaning these materials complements their aesthetics, further encouraging their usage.

Requirements and Standards

For designers and manufacturers looking to use 1060 patterned aluminum effectively, compliance with the following inherent specifications is vital:

Temper: The typical tempering for this alloy is H14, denoting strain-hardened after hot-forming—it offers a balance of strength and ductility ideal for many applications.

Thickness Varieties: Generally offered in sheet thicknesses of about 0.2 to 6.0 mm, custom dimensions can often be accommodated based on at-scale production needs.

Here is a quick reference table of chemical properties for 1060 Aluminum Alloy:

| Chemical Component | % Content (max) |

|---|---|

| Aluminum (Al) | 99.6 |

| Silicon (Si) | 0.25 |

| Iron (Fe) | 0.4 |

| Copper (Cu) | 0.05 |

| Manganese (Mn) | 0.05 |

| Magnesium (Mg) | 0.05 |

| Zinc (Zn) | 0.1 |

| Titanium (Ti) | 0.05 |

https://www.aluminumplate.net/a/pattern-aluminum-plate-1060.html