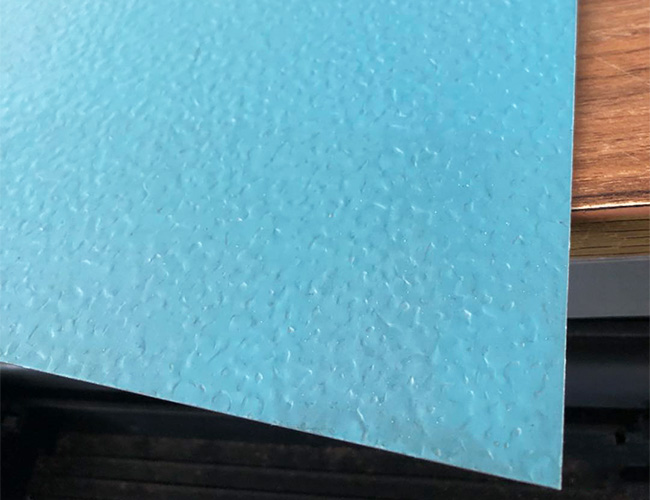

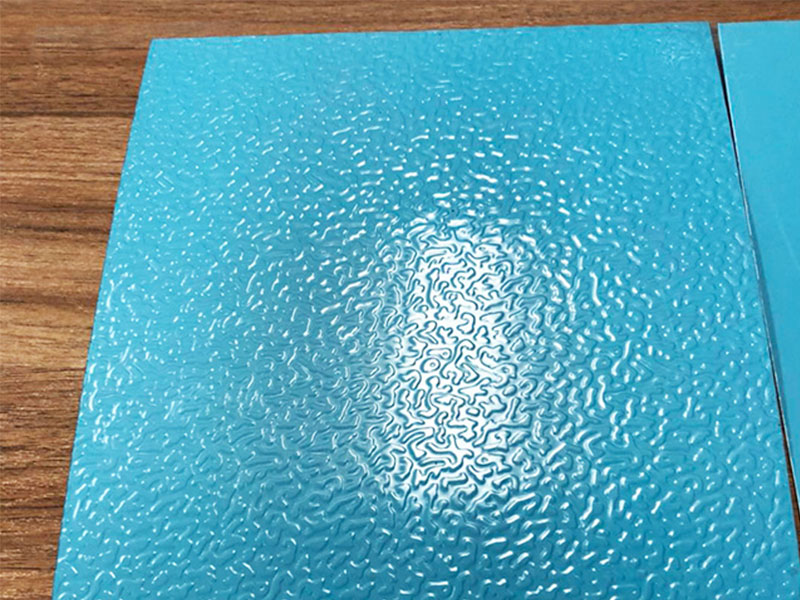

Stucco Finish Aluminum Sheet

A stucco finish aluminum sheet is often introduced as a "textured sheet," but that description feels too small for what it actually does. In the real world, this material behaves less like a flat metal product and more like a problem-solver that hides, protects, strengthens, and decorates at the same time. If smooth aluminum is a mirror that tells the truth-every small dent, ripple, and scratch-stucco finish is the practical friend that keeps a job looking clean even when life gets messy.

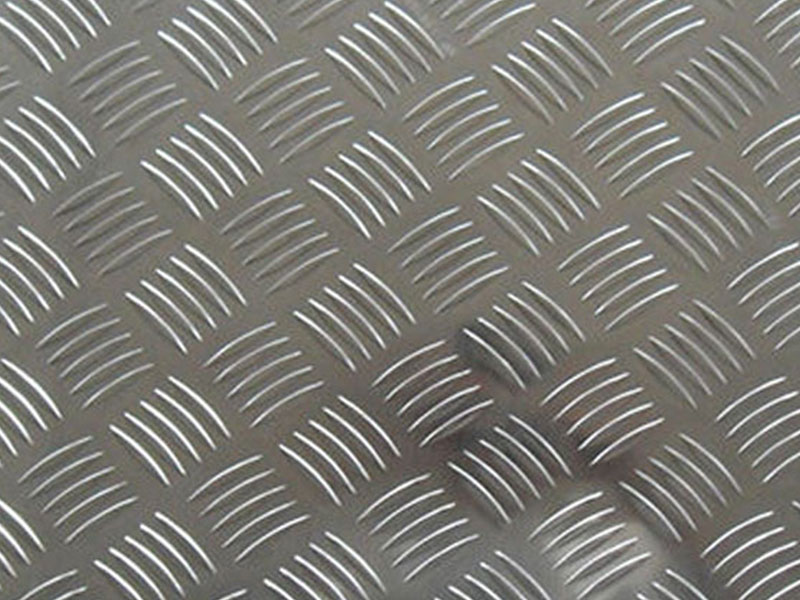

The distinctive value of stucco embossing is not just aesthetic. It is a quiet engineering trick: by forming a controlled pattern across the surface, the sheet resists visible damage, scatters reflections, and gains perceived stiffness. In applications such as refrigerator liners, cold-room panel skins, trailer sidewalls, cladding, heat insulation jacketing, appliance housings, and decorative trims, that "forgiving surface" can mean fewer rejects in fabrication and fewer complaints after installation.

What "stucco finish" really means in aluminum

Stucco finish is typically created by embossing a rolled aluminum sheet between patterned rolls. The result is a repeating, irregular pebble-like texture. Different mills use different embossing patterns-some tighter and finer, some deeper and more rugged-yet the goal is consistent: reduce glare, conceal handling marks, and enhance durability in day-to-day contact.

Because the texture breaks up reflection, stucco finish is popular where lighting is harsh or where a "premium but not glossy" look is desired. It also helps disguise oil canning effects in wide panels. That matters in architectural or transportation skins where large flat areas can visually distort when temperature changes or mechanical stresses occur.

Alloys and tempers: choosing the "personality" of the sheet

A stucco finish is a surface condition, not an alloy. The alloy and temper determine how the sheet will behave during forming, how it will resist corrosion, and how it will respond to service temperatures.

Common alloy families used for stucco finish include:

- 1xxx series (commercially pure aluminum such as 1050, 1060, 1100): excellent formability and corrosion resistance, strong thermal conductivity, lower strength.

- 3xxx series (Al-Mn such as 3003, 3105): a workhorse choice with better strength than 1xxx and very good formability; widely used for jacketing, appliance panels, and general fabrication.

- 5xxx series (Al-Mg such as 5052): higher strength and excellent marine corrosion resistance; preferred when extra durability or outdoor exposure is expected.

Temper selection is where practical decisions live. If you need deep drawing or complex bends, softer tempers such as O (annealed) or H14 are commonly chosen. If the panel must hold shape and resist denting, harder tempers like H24 or H32 may be more suitable. The embossing itself can slightly affect forming behavior because the surface geometry changes how the sheet slides against tooling and how strain distributes across the surface.

Typical temper notes used in procurement and production include:

- O temper: maximum ductility, best for aggressive forming.

- H14: half-hard, a balance of formability and stiffness.

- H24/H22: strain-hardened and partially annealed, improved formability vs. fully strain-hardened tempers.

- H32: stabilized (commonly for 5xxx), good for general forming and service stability.

Thickness, pattern depth, and what you feel in your hands

When people first touch stucco aluminum, they often comment on "grip." That tactile traction isn't just pleasant; it can reduce slipping during handling and assembly. Pattern depth and pitch matter here. A deeper emboss provides stronger visual masking and can feel more rigid, but it may also affect print-through in some laminated products or require careful selection if tight sealing surfaces are needed.

Common thickness ranges are broad, depending on the sector:

- Around 0.2–0.8 mm for appliance skins and decorative wraps

- Around 0.6–1.2 mm for insulation jacketing and general cladding

- Above 1.2 mm when greater rigidity or impact resistance is needed

In insulation jacketing, for example, stucco finish helps hide scuffs from ladders and tools during installation and maintenance. In transportation panels, it can maintain a cleaner appearance across long service intervals.

Practical standards and implementation references

In purchasing, the texture is often specified alongside base metal standards. The exact emboss pattern may be mill-specific, so it's important to confirm whether the requirement is "stucco finish in general" or a particular pattern depth and look.

Commonly referenced standards for aluminum sheet include:

- ASTM B209 / B209M: Aluminum and Aluminum-Alloy Sheet and Plate

- EN 485 (Europe): aluminum and aluminum alloy sheet/strip tolerances and mechanical properties

- EN 573 (Europe): chemical composition for wrought aluminum alloys

- JIS H4000 series (Japan) and related JIS standards for wrought aluminum products

Surface expectations can also be guided by general commercial tolerance and finish agreements between supplier and buyer. If a project needs repeatable appearance across batches, requesting reference samples and defining acceptable variation is more effective than relying on a generic "stucco" term alone.

Corrosion behavior and surface treatments

Aluminum naturally forms an oxide film that provides corrosion resistance in many environments. Stucco texture doesn't inherently reduce corrosion resistance, but it does increase surface area slightly and can retain contaminants if not cleaned. In outdoor applications, especially coastal or industrial atmospheres, choosing an alloy like 5052 or a properly coated 3xxx product can improve longevity.

Common surface options include:

- Mill finish stucco: natural aluminum appearance, economical, widely used.

- Pre-painted stucco (coil coating): used for cladding and decorative panels; requires paint systems suitable for forming and outdoor exposure.

- Anodized stucco: less common than flat anodized sheet, but possible depending on pattern and aesthetic goals.

If the sheet is used in contact with dissimilar metals, galvanic corrosion design rules still apply. Isolation tapes, compatible fasteners, and appropriate sealants remain important even with textured surfaces.

Fabrication: forming, cutting, joining

Stucco finish is generally easy to cut, shear, and punch using typical aluminum practices. During bending, the emboss can slightly influence how the bend line looks, especially if the bend is across a deep pattern. When appearance is critical, shops often test bend direction relative to rolling direction and emboss orientation, then lock in the best practice.

Welding is alloy-dependent. 3xxx and 5xxx alloys weld well with appropriate filler selection. For thin sheets in appliance or insulation markets, mechanical fastening, adhesives, and lock-form seams are more common than welding. Pre-painted stucco requires care to avoid coating damage; using protective films and clean tooling helps prevent "tracking" or marring across the raised pattern.

Chemical composition table (typical ranges)

Below are typical composition limits for common alloys used in stucco finish aluminum sheet. Values are representative of widely used standards; always confirm with mill test certificates and the governing specification for your order.

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | - | ≤0.05 | ≤0.03 | ≥99.50 |

| 1060 | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | ≤0.03 | - | ≤0.05 | ≤0.03 | ≥99.60 |

| 1100 | ≤0.95 (Si+Fe) | - | 0.05–0.20 | ≤0.05 | - | - | ≤0.10 | ≤0.05 | Rem. |

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | - | - | ≤0.10 | - | Rem. |

| 3105 | ≤0.60 | ≤0.70 | ≤0.30 | 0.30–0.80 | 0.20–0.80 | - | ≤0.40 | ≤0.10 | Rem. |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | - | Rem. |

A material that "stays looking finished"

When you specify it wisely-matching alloy to environment, temper to forming needs, thickness to stiffness, and pattern to appearance-you're not just buying aluminum with texture. You're buying a surface strategy: one that turns the unavoidable marks of manufacturing and maintenance into something that barely registers. In many industries, that small advantage is the difference between "it works" and "it keeps working while still looking like it belongs."

https://www.aluminumplate.net/a/stucco-finish-aluminum-sheet.html