Embossed Alloy 3003 Aluminum circle

Embossed Alloy 3003 Aluminum Circle: Function, Performance & Real-World Value

Embossed alloy 3003 aluminum circle is more than just a shaped piece of metal. It is a carefully engineered material that blends alloy chemistry, surface texture, and temper conditions to solve practical problems in cookware, lighting, decorative panels, and industrial components. it from a functional point of view helps you choose the right specification quickly and confidently.

What makes alloy 3003 different?

Alloy 3003 belongs to the aluminum–manganese (Al–Mn) family. Unlike pure aluminum (such as 1050 or 1100), 3003 contains manganese as the main alloying element. This seemingly small addition creates a big shift in behavior:

- Higher strength than commercially pure aluminum

- Better resistance to corrosion in humid, food-grade, and mildly chemical environments

- Excellent formability for deep drawing and spinning

- Reliable thermal conductivity for heat-transfer applications

When this alloy is produced as a circle and given an embossed surface, its performance becomes particularly useful in applications that involve gripping, cooking, reflecting, or decorating.

Why an embossed circle instead of a flat sheet?

Embossing introduces a raised or textured pattern on the surface of the aluminum circle. From a functional standpoint, this changes how the material behaves in several ways:

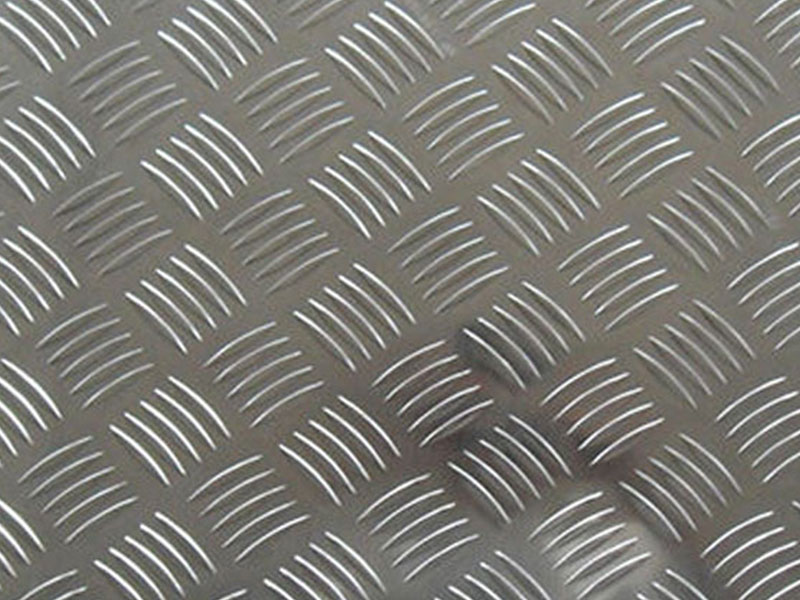

- Improved grip and anti-slip behavior when used as a contact or handling surface

- Enhanced visual appearance with patterns that scatter light, hide minor scratches, and add perceived quality

- Slightly increased structural stiffness due to work hardening and micro-shaping of the surface

- Better heat diffusion patterns in some cookware designs, depending on embossing type and thickness

For cookware, lighting reflectors, decorative plates, and appliance components, the circle shape is production-ready: it feeds directly into spinning, deep drawing, stamping, or pressing operations without extra cutting or trimming, reducing scrap and cycle time.

applications of embossed 3003 aluminum circles

From a practical perspective, embossed 3003 circles are chosen because they perform reliably in use and process smoothly in manufacturing.

Common uses include:

Cookware and kitchenware

Frying pans, soup pots, rice cookers, pressure cooker bodies, and lids. The alloy provides good thermal conductivity and can be deep-drawn without cracking or orange peeling. The embossed surface can help in non-visible areas to reduce contact sticking or in visible areas to add a decorative identity.Lighting and reflectors

Downlight reflectors, lamp shades, and decorative rings often use embossed circles to diffuse light and reduce glare. The texture softens reflections while the alloy maintains shape after spinning and forming.Appliance and interior components

Decorative front panels, small covers, fan housings, and interior trims use embossed 3003 circles when a combination of corrosion resistance, lightweight design, and surface texture is required.Industrial and protective discs

End-caps, protective covers for valves or instruments, and filter housings take advantage of the alloy’s good corrosion resistance and ease of forming. The embossed pattern helps resist visible scratching and wear.

In many of these cases, the choice of 3003 over other alloys comes down to one balance: stronger and more corrosion-resistant than pure aluminum, yet still soft and ductile enough to form complex shapes economically.

Alloy tempers and what they mean in practice

The same alloy behaves differently under different temper conditions. For embossed 3003 aluminum circles, the most common tempers are:

O (annealed)

Fully softened, maximum formability, lower strength. This is the preferred temper for deep drawing and heavy spinning, where the metal must stretch without tearing.H12, H14, H16 (strain-hardened)

These are work-hardened tempers with progressively higher strength and lower ductility.- H12: light strain hardening, good compromise between strength and formability

- H14: medium strength, often used where moderate forming is required

- H16: higher strength, used when forming is minor and strength/stiffness is more important

Choosing the right temper depends on the forming depth, spinning speed, and final mechanical requirements. For a deep soup pot body, O temper or H12 is often favored. For a shallow pan or a decorative cover with limited draw, H14 can provide a stiffer result and better dent resistance.

Typical dimensions and technical parameters

Producers tailor embossed 3003 circles to match the needs of cookware and industrial customers. Typical technical parameters include:

Diameter range

Generally from about 100 mm up to 1,200 mm, depending on the press and coil width. Smaller circles are used for small pans, lids, and lamp reflectors; larger ones for big pots, catering equipment, and industrial covers.Thickness range

Usually from 0.5 mm to about 6.0 mm.- Thin gauges (0.5–1.0 mm) are common in lamp reflectors and small kitchenware

- Medium gauges (1.2–3.0 mm) for general cookware and appliance parts

- Heavier gauges (above 3.0 mm) for industrial covers and structural discs

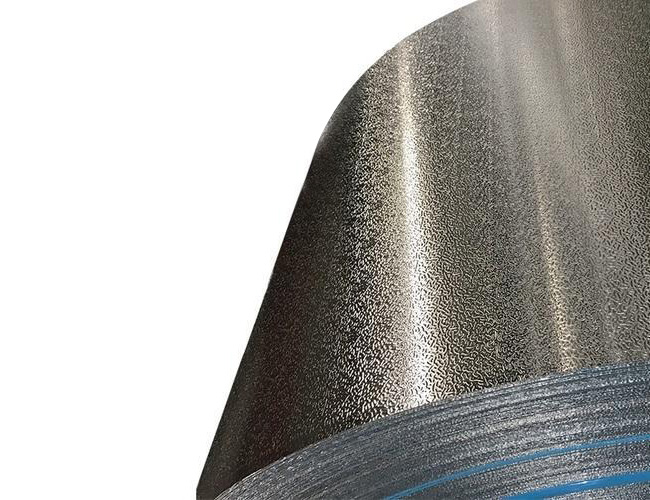

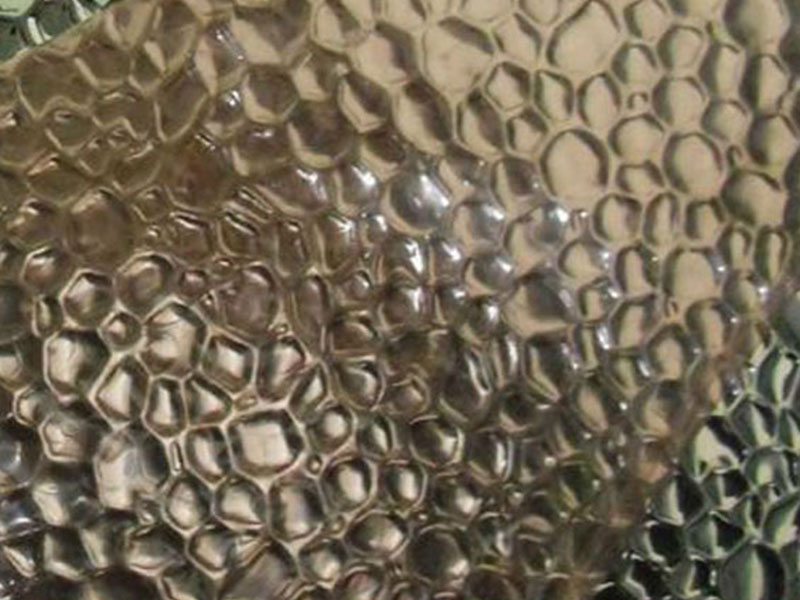

Surface patterns

Common embossing styles include orange peel, stucco, diamond, and linen textures. The choice is largely aesthetic but also slightly affects stiffness, friction, and light reflection.Surface finish and protection

Circles can be supplied mill-finished, lightly brushed, or pre-treated for later anodizing or coating. To prevent scratches, interleaving paper or plastic film is often added between pieces.

Implementation standards and quality control

High-quality embossed 3003 aluminum circles are usually produced in line with international or regional standards to ensure consistency in chemistry, mechanical properties, and dimensional accuracy.

Common reference standards include:

- ASTM B209 (Aluminum and Aluminum-Alloy Sheet and Plate)

- EN 485 / EN 573 (European standards for aluminum sheet and chemical composition)

- GB/T standards in China for alloy 3003 sheet and strip

In a production environment, this translates into:

- Controlled alloy composition according to 3003 specifications

- Consistent temper through accurate cold rolling and annealing cycles

- Tight tolerances on thickness and diameter for efficient automated forming

- Flatness and minimal residual stress to avoid warping during spinning or drawing

- Uniform embossing pattern with stable depth and coverage

For customers, certificates of analysis and mechanical-property test reports help validate that incoming circles are suitable for high-speed forming lines and maintain consistent product quality.

Chemical composition of alloy 3003

The defining feature of 3003 is its manganese addition. A typical chemical composition range is:

| Element | Typical Range (%) |

|---|---|

| Aluminum (Al) | Balance |

| Manganese (Mn) | 1.0 – 1.5 |

| Copper (Cu) | 0.05 – 0.20 |

| Silicon (Si) | ≤ 0.6 |

| Iron (Fe) | ≤ 0.7 |

| Zinc (Zn) | ≤ 0.10 |

| Others, each | ≤ 0.05 |

| Others, total | ≤ 0.15 |

This composition gives 3003 its characteristic combination of:

- Improved strength over 1xxx series

- Good resistance to atmospheric and food-related corrosion

- High ductility and excellent deep-draw performance

The presence of manganese strengthens the alloy through solid-solution hardening, while the low copper level maintains corrosion resistance, especially important in cookware and humid storage conditions.

Functional benefits at a glance

From a buyer’s viewpoint, embossed alloy 3003 aluminum circles deliver several clear advantages:

Process efficiency

Ready-to-use circle blanks reduce cutting steps, scrap, and handling. Consistent temper and flatness support high-speed spinning and deep drawing.Product performance

Good strength-to-weight ratio, improved corrosion resistance, and reliable thermal conductivity help cookware perform evenly and last longer.Aesthetics and branding

Embossed patterns create a distinct appearance, enhance perceived quality, and can be used to differentiate product lines in both cookware and lighting.Safety and ergonomics

Anti-slip and low-glare surface textures improve safety and user comfort in both household and industrial settings.

Choosing the right embossed 3003 circle for your application

Matching the material to your process is crucial. When specifying embossed 3003 aluminum circles, consider:

- Forming depth and method: deep drawing, spinning, stamping, or shallow forming

- Required stiffness versus required ductility: choose O, H12, or H14 accordingly

- Desired surface appearance: pattern type, brightness, post-processing like anodizing or coating

- End-use environment: food contact, humidity, mild chemicals, outdoor usage

With the correct alloy temper, thickness, embossing style, and diameter, embossed 3003 aluminum circles become a highly efficient, multi-functional base material that supports both industrial productivity and attractive final products.

https://www.aluminumplate.net/a/embossed-alloy-3003-aluminum-circle.html