3003 H22 Embossed Aluminum Tread Sheet

Aluminum tread plates have become an integral part of various industrial and commercial Applications due to their high durability, lightweight, and versatile nature. Among these products, the 3003 H22 Embossed Aluminum Tread Sheet stands out due to its unique combination of physical properties, applications, and workability.

What is 3003 H22 Embossed Aluminum Tread Sheet?

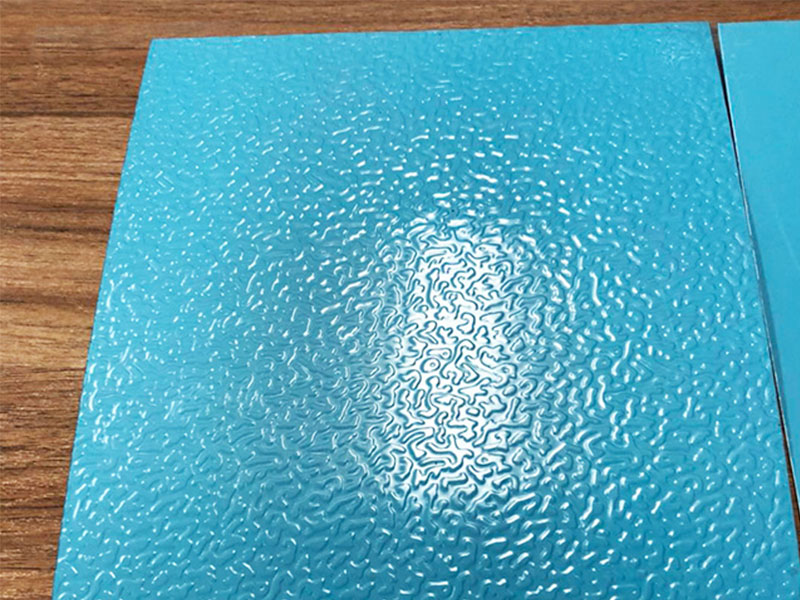

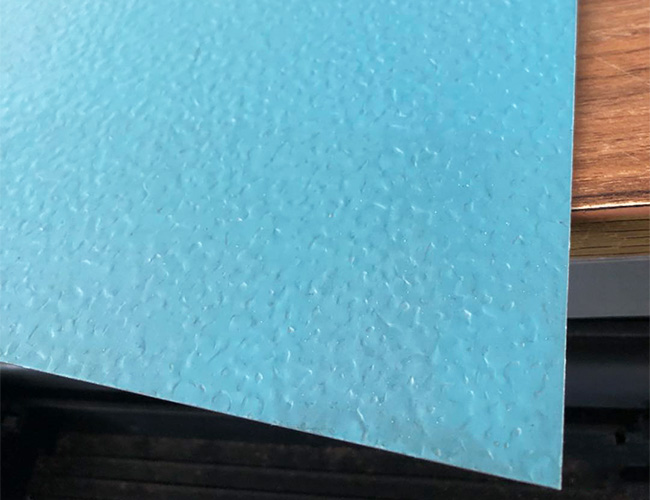

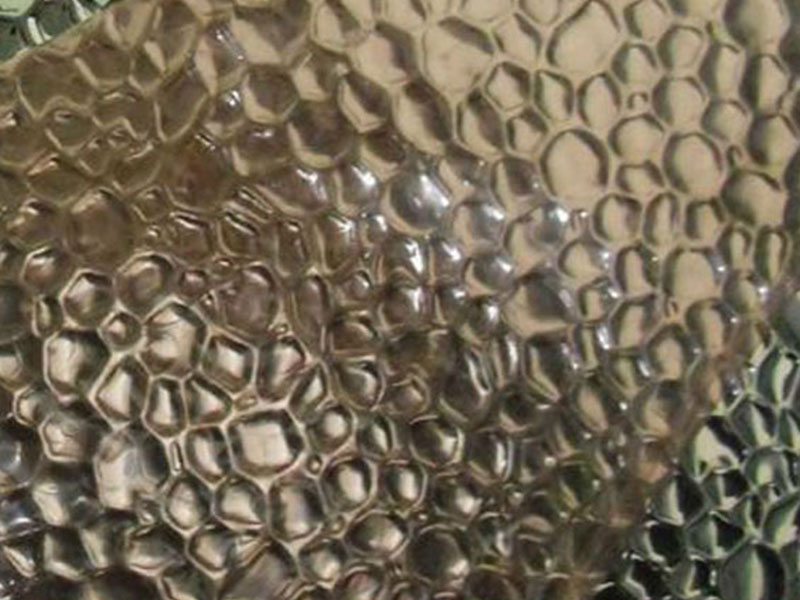

The 3003 H22 aluminum tread sheet is an alloy made predominantly from aluminum, using during manufacturing a different tempering and embossing process. This inherent combination creates a structured surface that significantly improves traction and minimizes slipping, which is especially crucial for fleet trucks, walkways, stairs, and toolboxes.

Features and Functions

- Corrosion Resistance: Aluminum 3003 has excellent resistance to corrosion, making it suitable for various environments, including moist and saline surroundings.

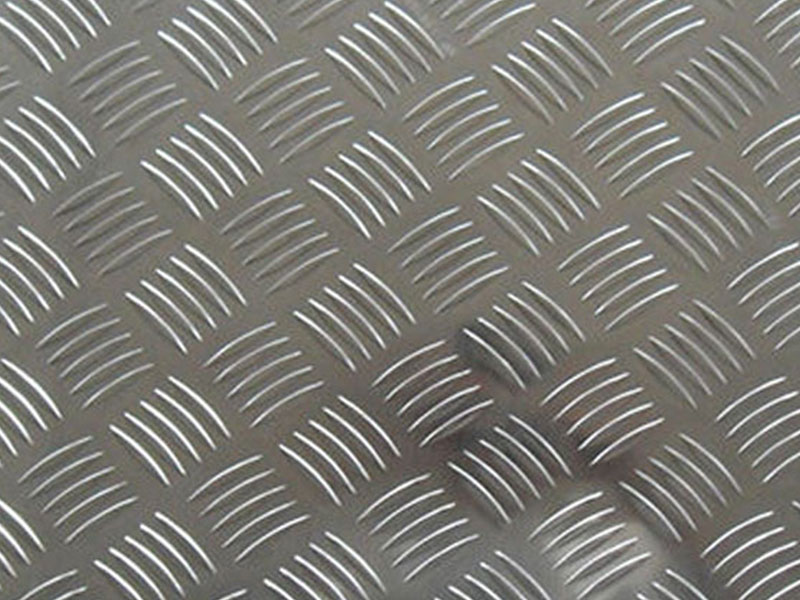

- Enhanced Traction: The embossed pattern creates a nodded surface that reduces slippage, facilitating safer transit over those surfaces.

- Weight Advantage: A big selling point of aluminum products, including 3003 H22, is their lightweight. This decreases the weight of onboard materials, ultimately improving efficiency and ease in handling parts.

- Thermal and Electrical Conductivity: 3003 series alloys boast of good conductivity, suitable for applications where heat dissipation is necessary.

Common Applications

The 3003 H22 embossed aluminum tread sheet is often utilized in various industries for:

- Transport and Commercial Vehicles: Truck and trailer floors, e.g., beds and tool boxes to ensure fittings.

- Architectural Elements: Walkways, ramps, stairs and wall coverings where both strength and slip resistance are needed.

- Commercial Construction: Equipment trays and even interior renovations due to its appealing look and strength.

- Food and Chemical Industries: Where hygiene and corrosion resistance are stemming concerns due to food contact or harsh chemical environments.

Technical Specifications

The physical and chemical properties of the 3003 H22 Embossed Aluminum Tread Sheet are vital for gauging the suitability of this material for specific applications.

1. Chemical Composition

The following table outlines the chemical composition of 3003 alloy.

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | ≥ 94.7 |

| Copper (Cu) | 0.12 - 0.20 |

| Manganese (Mn) | 1.0 - 1.5 |

| Silicon (Si) | 0.6 |

| Iron (Fe) | 0.7 |

| Zinc (Zn) | 0.1 |

| Magnesium (Mg) | 0.1 |

2. Mechanical Properties

Mechanical properties help determine how the material behaves during processing or assembly.

| Property | Value |

|---|---|

| Yield Strength (YS) | 130-150 MPa |

| Ultimate Tensile Strength (UTS) | 205-250 MPa |

| Elongation (in 50mm) | 20% |

| Hardness (Brinell) | 60-80 HB |

| Density | 2.73 g/cm³ |

3. Tempering Conditions

- Heat Treatment: 3003 can be cold worked to increase its strength typically involved in producing H22 property.

- Max Brinell Hardness at State: 60 si to reinforce compliance to alloy engineering heat-treat considerations.

4. Implementation Standards

The 3003 H22 Aluminum Tread Sheet complies with a variety of international and industry standards:

- ASTM B209: Standard Specification for Aluminum and Aluminum-Alloy Sheets and Plates.

- ASTM D2104: Specification for Visual and Color Selection Standards of Metallic Covers.

- ANSI H35.2: Alloy and Temper Data for Commercial Aluminum Sheets.

https://www.aluminumplate.net/a/3003-h22-embossed-aluminum-tread-sheet.html