1060 H18 anodized mirror aluminum coil

The 1060 H18 anodized mirror aluminum coil is a high-purity, high-reflectivity rolled aluminum product, specially treated to deliver a bright, mirror-like surface with excellent durability. It is widely used in lighting, decoration, solar energy, reflective panels, and a variety of industrial and consumer products where appearance and light control matter.

Aluminum 1060 is a commercially pure aluminum alloy with at least 99.6% aluminum content. The H18 temper indicates it is in a full-hard, cold-worked condition, providing higher strength than fully annealed 1060 while still retaining good formability for certain bending and stamping operations.

| Item | Description |

|---|---|

| Alloy designation | 1060 |

| Temper | H18 (full hard, strain-hardened) |

| Aluminum purity | ≥ 99.6% |

| Product form | Coil (rollable, slit, or rewound) |

| Surface finish | Anodized mirror / high-reflective |

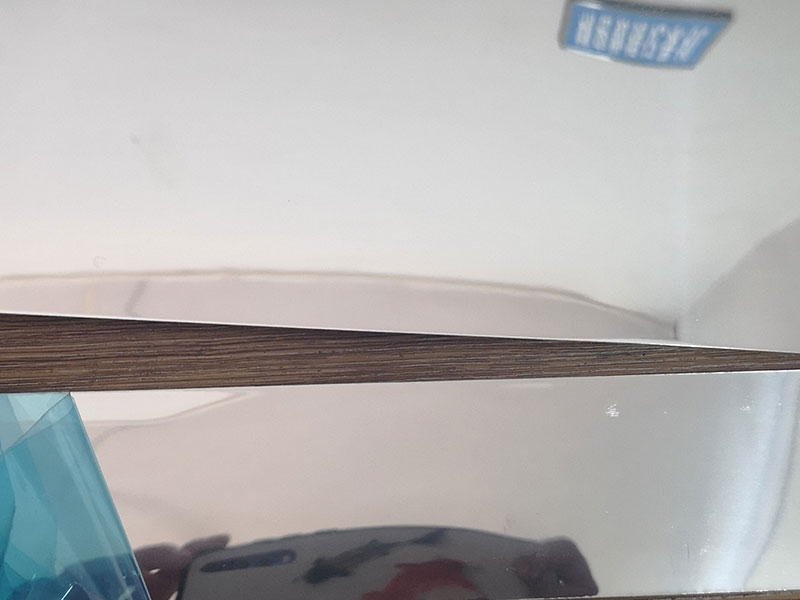

| Typical thickness range | ~0.2 – 2.0 mm (customizable by supplier) |

| Typical width range | ~200 – 1600 mm (customizable by supplier) |

| Standard specification | Based on GB/T, ASTM B209 or EN AW-1050A equiv. |

Chemical Composition of 1060 Aluminum

As a near-pure aluminum, alloy 1060 contains very low levels of alloying elements. This high purity contributes to excellent corrosion resistance and good electrical and thermal conductivity.

| Element | Typical Max Content (%) | Function / Effect |

|---|---|---|

| Al | Balance (≥ 99.6) | Base metal; high conductivity, corrosion resistant |

| Si | ≤ 0.25 | Slightly improves strength, affects fluidity |

| Fe | ≤ 0.35 | Influences strength and surface finish |

| Cu | ≤ 0.05 | Excess may reduce corrosion resistance |

| Mn | ≤ 0.03 | Trace; minor effect on strength |

| Mg | ≤ 0.03 | Trace; minor effect on strength |

| Zn | ≤ 0.05 | Trace; may influence corrosion behavior |

| Ti | ≤ 0.03 | Grain refinement in some products |

| Others (each) | ≤ 0.03 | Impurities |

| Others (total) | ≤ 0.10 | Impurities |

Exact limits may vary slightly by standard (GB, ASTM, EN) and producer, but the emphasis remains very high aluminum content.

Temper H18 and Mechanical Properties

The H18 temper means the coil is cold-worked to a full-hard condition without subsequent annealing. This raises strength but reduces elongation compared with soft tempers such as O or H14.

Typical mechanical properties for 1060 H18 anodized mirror aluminum coil:

| Property | Typical Value Range | Notes |

|---|---|---|

| Tensile strength Rm | 135 – 165 MPa | Depends on thickness and process |

| Yield strength Rp0.2 | ≥ 115 MPa | Higher than softer tempers |

| Elongation A50 | 1 – 5 % | Lower ductility due to full-hard temper |

| Brinell hardness HB | ~35 – 45 HB | Higher hardness than O temper |

| Modulus of elasticity | ~70 GPa | Similar for most aluminum alloys |

| Density | ~2.70 g/cm³ | Lightweight material |

| Electrical conductivity | ~55–57 % IACS | High due to high Al purity |

| Thermal conductivity | ~230 W/(m·K) | Very good heat conduction |

For demanding forming operations, softer tempers may be preferred, but H18 is well suited to flat panels, reflective plates, and applications requiring stiffness and dimensional stability.

Anodized Mirror Surface Characteristics

The “mirror” finish is achieved through high-quality rolling and polishing, followed by anodizing, which creates a controlled aluminum oxide layer. This combination delivers both high reflectivity and surface protection.

| Surface Parameter | Typical Feature |

|---|---|

| Surface gloss | High-gloss mirror, uniform reflection |

| Reflectivity (specular) | Approx. 80–92% (depending on grade and finish) |

| Anodic film thickness | ~3 – 10 μm (decorative / protective level) |

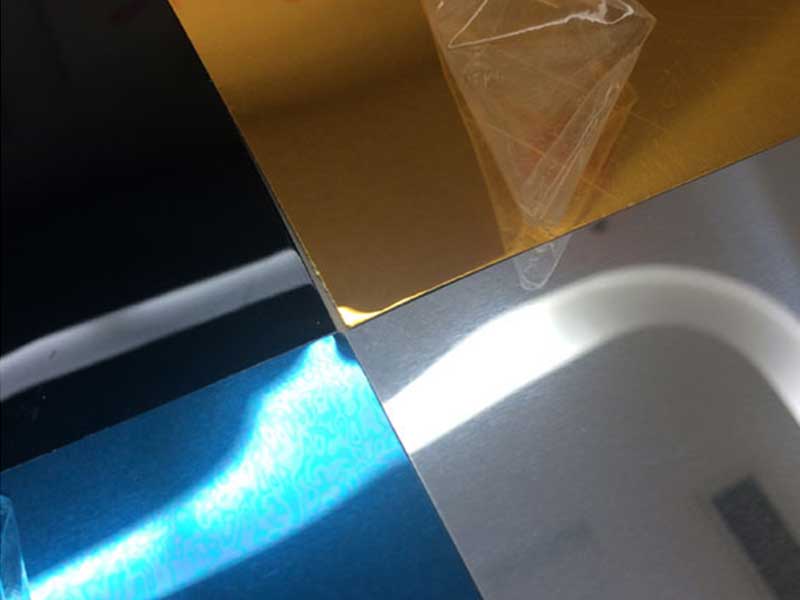

| Color options | Natural silver, or colored via dyeing/electrocoloring |

| Surface defects | Low; controlled for scratches and rolling marks |

| Stain / corrosion resistance | Improved vs. non-anodized due to oxide layer |

| Cleanability | Easy to clean; suitable for interior and many exterior uses |

Reflectivity values depend on the polishing quality, anodizing process, and specific product series (standard mirror, high-reflective, diffuse-reflective versions).

Features and Advantages

The 1060 H18 anodized mirror aluminum coil combines its base alloy properties with advanced surface treatment. Major benefits include:

| Feature Category | Description / Customer Benefit |

|---|---|

| High reflectivity | Enhances light output, reduces energy loss in lighting and solar systems |

| Lightweight | Lower weight than steel or copper; easier handling and installation |

| Corrosion resistance | Anodized layer protects against oxidation and atmospheric corrosion |

| Aesthetic appeal | Bright, clean, modern appearance suitable for visible applications |

| Processability | Can be cut, slit, bent (with limits), stamped, and bonded |

| Environmental profile | Recyclable material; anodizing has low impact compared with painting |

| Electrical/thermal | Good conductivity for heat spreaders and some electrical components |

| Cost-effectiveness | Economic option for large reflective or decorative surfaces |

Typical Technical Specifications (Reference)

Exact specifications vary by supplier and project, but a typical product range for 1060 H18 anodized mirror aluminum coil might be:

| Item | Typical Range / Option |

|---|---|

| Thickness | 0.20 – 1.50 mm (special orders possible) |

| Width | 300 – 1500 mm |

| Coil inner diameter (ID) | 150, 405, 505 mm (common) |

| Coil outer diameter (OD) | Up to ~1200 – 1500 mm |

| Coil weight | ~0.5 – 3.0 tons per coil (customizable) |

| Surface type | Mirror, bright, brushed + anodized, etc. |

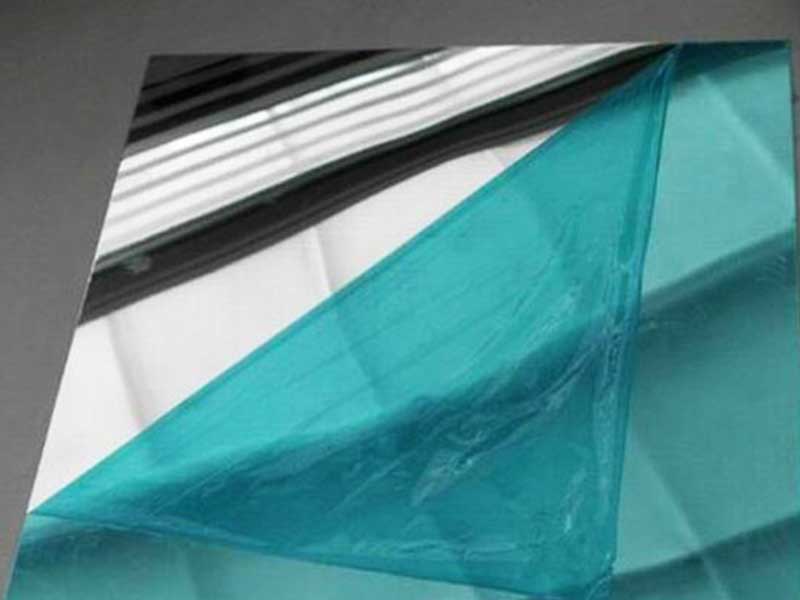

| Protective film | PE or PVC film on mirror side (single or both sides) |

| Anodizing type | Decorative / protective, clear or colored |

| Tolerance on thickness | As per standard (e.g., ±0.02–0.05 mm) |

| Tolerance on width | As per order (e.g., ±0.5 – 2.0 mm) |

Customers should confirm exact tolerances and ranges with the supplier’s datasheet and order specification.

Main Application Fields

Because of its optical performance and clean metallic look, 1060 H18 anodized mirror aluminum coil is widely used in both functional and decorative roles.

Lighting and Illumination

| Application Target | Function / Advantage |

|---|---|

| Indoor luminaires | Reflector plates increase lighting efficiency |

| LED light housings | Enhances light distribution and aesthetics |

| Downlights, panel lights | Lightweight reflector and trim components |

| Commercial lighting fixtures | High reflectivity reduces power consumption |

The mirror surface helps direct light where it is needed, improving fixture efficacy while maintaining a sleek design.

Solar and Energy-related Uses

| Application Target | Function / Advantage |

|---|---|

| Solar collector reflectors | Concentrate sunlight onto absorber tubes |

| Photovoltaic auxiliary reflectors | Improve light capture on PV modules |

| Light-guiding and daylight systems | Reflect and redirect natural light indoors |

Using high-reflective aluminum improves system efficiency while keeping structures light and corrosion-resistant.

Architectural and Interior Decoration

| Application Target | Function / Advantage |

|---|---|

| Ceiling panels and tiles | Adds brightness and visual space without heavy glass |

| Wall cladding and trims | Modern metallic look, durable surface |

| Elevator interiors, columns | Decorative mirror finish with easy maintenance |

| Signage and display panels | High visual impact, good print adhesion (on suitable treatments) |

Mirror aluminum can substitute glass mirrors in many cases where low weight and shatter resistance are essential.

Consumer and Industrial Products

| Product Type | Example Uses |

|---|---|

| Home appliances | Decorative strips, control panels, front covers |

| Furniture and cabinet panels | Decorative inlays, light-reflective accents |

| Automotive / transport parts | Interior trim, reflective components, bus/coach decor |

| Instrument panels and enclosures | Front plates, nameplates, scale plates |

| HVAC and reflector ducts | Reflective air ducts, thermal management panels |

The combination of formability, conductivity, and appearance makes this coil suitable across many sectors.

Processing and Fabrication Considerations

To maintain the mirror quality and structural performance, some fabrication guidelines are recommended:

| Process Step | Recommendation / Note |

|---|---|

| Cutting / slitting | Use sharp, clean tooling; protect surface with film |

| Bending | Observe minimum bend radius; H18 has limited formability |

| Stamping / punching | Avoid deep draws; polish or protect dies to prevent scratches |

| Surface protection | Keep protective PE film on during processing and transport |

| Cleaning | Use neutral detergents; avoid strong alkali/acids that attack anodic layer |

| Bonding / lamination | Compatible with many adhesives; test for adhesion on anodized surface |

For complex deep-forming parts, switching to a softer temper (such as 1060 O or H14) with later anodizing may be more suitable.

Quality Control and Standard Compliance

Reliable 1060 H18 anodized mirror aluminum coil is typically produced under controlled conditions with:

| Control Aspect | Typical Focus Point |

|---|---|

| Dimensional control | Thickness, width, flatness, edge quality |

| Surface inspection | Scratches, streaks, pits, color uniformity |

| Reflectivity testing | Specular and total reflectance |

| Anodic film tests | Thickness, hardness, adhesion, corrosion resistance |

| Mechanical tests | Tensile, yield, elongation according to standards |

Compliance with standards such as ASTM B209, EN 485/573, or national GB/T specifications ensures predictable performance and consistent quality from coil to coil.

The 1060 H18 anodized mirror aluminum coil offers a well-balanced combination of:

- High aluminum purity for conductivity and corrosion resistance

- Full-hard temper for flatness and strength

- Anodized mirror finish for high reflectivity and decoration

Its versatility makes it ideal for lighting reflectors, solar energy systems, architectural trim, interior decoration, appliances, and a wide range of industrial and consumer products where both appearance and performance are critical.

By its chemical composition, mechanical behavior, and processing requirements, customers can specify and apply 1060 H18 anodized mirror aluminum coil effectively in demanding projects.

https://www.aluminumplate.net/a/1060-h18-anodized-mirror-aluminum-coil.html