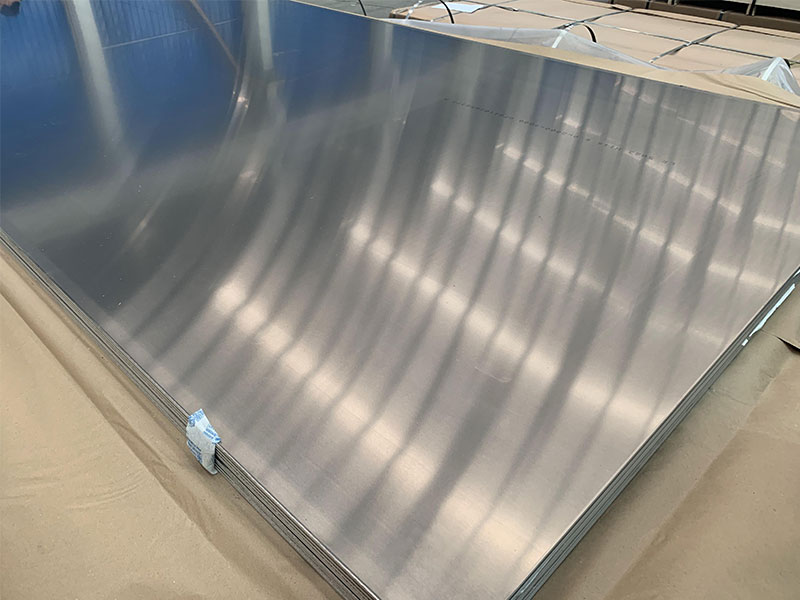

5052 5083 marine grade aluminum sheets

When it comes to maritime applications, not all materials are created equal. As the backbone of shipbuilding and marine technology, aluminum has emerged as a beacon of durability and versatility, with the alloys 5052 and 5083 particularly shining in marine environments.

A Natural Resilience Against Corrosion

One of the foremost considerations in marine applications is a material's ability to withstand harsh environments. The sea, with its saltwater and varying temperatures, can be unforgiving, leading to corrosion in unprotected metals. Both 5052 and 5083 aluminum alloys boast exceptional resistance to corrosion, making them viable choices for ship hulls, deck structures, and other sea-facing components.

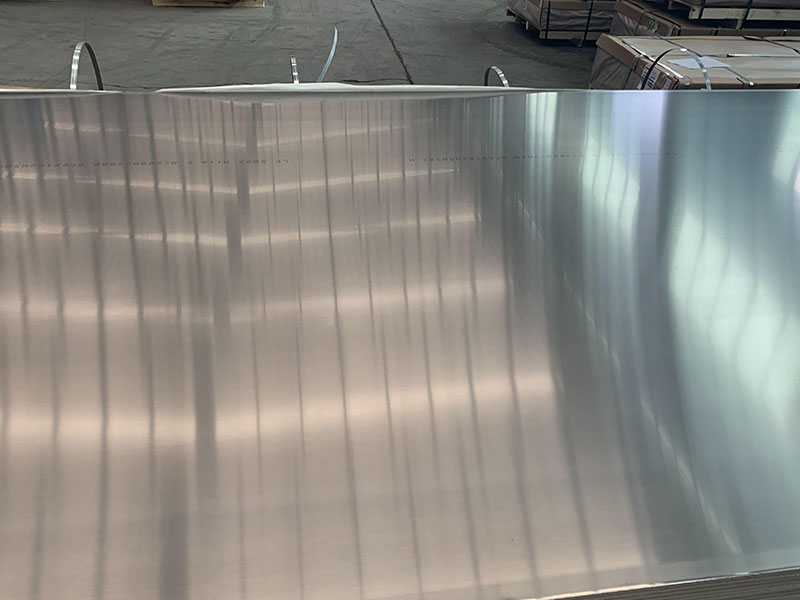

5052 Aluminum: Known for its good workability and formability, the 5052 aluminum alloy thrives in marine environments due to its higher magnesium content, which fortifies its resistance to saltwater corrosion. The composition typically features around 2.5% magnesium and 0.25% chromium, aiding its adaptability and long-term performance.

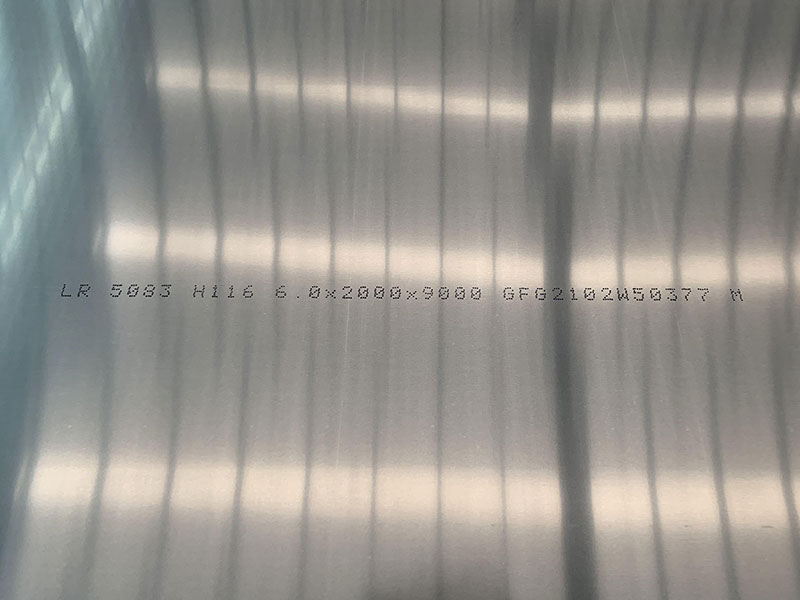

5083 Aluminum: Raised to the next level of durability and strength, the 5083 aluminum sheet incorporates up to 4.3% magnesium and a higher percentage of manganese. It provides robust mechanical properties that ensure resilience under pressure, for hulls exposed to the vicious forces of high seas.

Distinctive Properties: Beyond the Basics

| Property | 5052 Aluminum | 5083 Aluminum |

|---|---|---|

| Chemical Composition | 2.5% Mg, 0.25% Cr or higher; balance Al | Up to 4.3% Mg, 0.7-1.4% Mn; balance Al |

| Density | 2.68 g/cm³ | 2.66 g/cm³ |

| Tensile Strength | 210 MPa (30.5 ksi) | 317 MPa (46 ksi) |

| Yield Strength | 193 MPa (28 ksi) | 250 MPa (36 ksi) |

| Corrosion Resistance | Excellent | Excellent |

| Weldability | Good | Very Good |

| Workability | High | Moderate |

| Applications | Fuel tanks, marine devices | Shipbuilding, pressure vessels |

These parameters elucidate their capabilities, positioning 5083 as the stronger sibling with unparalleled performance under mechanical stress, while 5052 emerges as the champion of formability and ease of crafting into various shapes.

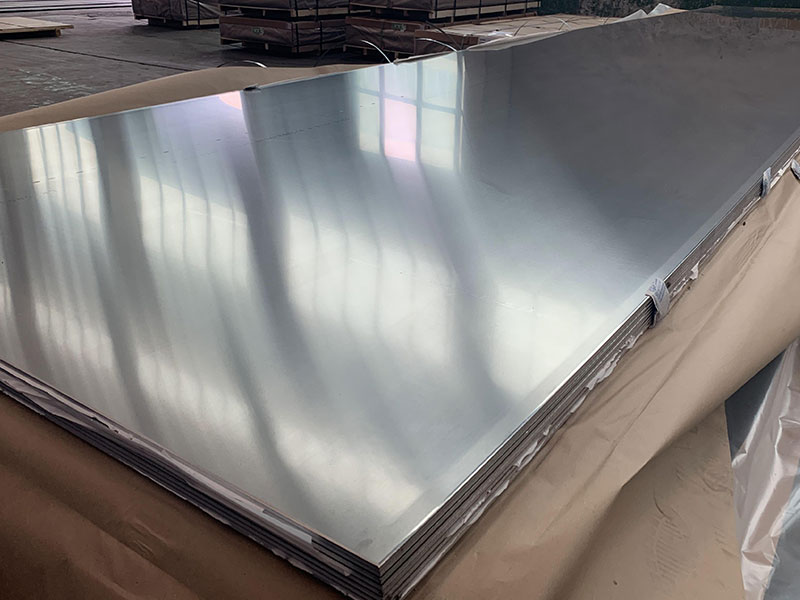

Fabrication Standards and Methods

An essential aspect of both 5052 and 5083 aluminum sheets is how they can be carefully transformed into functional maritime structures. Adherence to various fabrication standards goes a long way in ensuring that the finished components can endure unpredictable sea climates. Whether it involves cutting, welding, or forming, it’s vital that the processed sheets take advantage of their innate properties.

Welding: Both alloys are highly weldable. 5083, in particular, is ideal for the construction of complex shapes used in shipbuilding and offshore structures, where strong joints in structures are prerequisite.

Finishing: Anodizing is a popular finish used particularly with marine-grade aluminum sheets like 5052 and 5083. This oxide layer enriches corrosion resistance while offering a pleasing aesthetic.

Sustainable Choice

In today’s environmentally conscious world, sustainable practices are a paramount consideration in material selection. Aluminum, being highly recyclable, is a major contributor to sustainability in construction and manufacturing. With both 5052 and 5083 alloys, we can recycle and reuse material without compromising quality, thus lowering environmental impact.

https://www.aluminumplate.net/a/5052-5083-marine-grade-aluminum-sheets.html