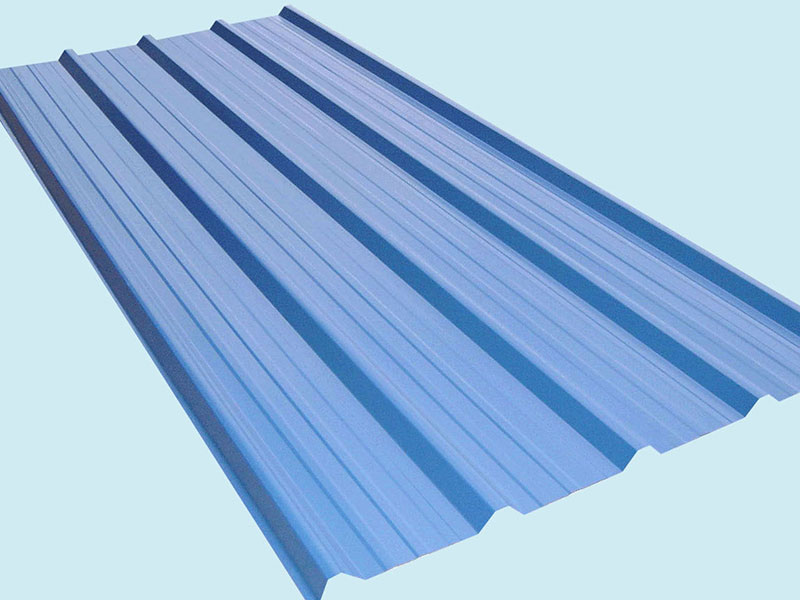

A3003 1.0mm Thick Color Coated Aluminum Sheet for Roofing

In the fast-paced world of construction and design, material selection plays a pivotal role in ensuring both aesthetic appeal and structured integrity. Among the esteemed options available today, the A3003 1.0mm Thick Color Coated Aluminum Sheet shines brightly, particularly for roofing applications.

A3003 Aluminum Alloy

The A3003 series aluminum is one of the most popular non-heat-treatable alloys, known for its good workability and corrosion resistance. Lets break down its significance based on its chemical composition, intentionally formulated for balanced weight and strength.

Chemical Properties

| Element | Percentage by Weight |

|---|---|

| Aluminum | Balance |

| Manganese | 1.0-1.5% |

| Copper | 0.05-0.20% |

| Magnesium | 0.05% max |

| Zinc | 0.10% max |

| Silicon | 0.60% max |

| Iron | 0.7% max |

Features of A3003

Beyond its chemical profile, the A3003 aluminum can be characterized with the following endpoints:

- Thickness: With a reliable thickness of 1.0mm, this aluminum sheet offers enviable durability street cred given its durability.

- Color Coating: The color coating process not only facilitates effective weather resistance but also adds to its visual appeal, making it perfect for a variety of architectural presentations.

Implementation Standards

The prowess of the A3003 1.0mm Thick Color Coated Aluminum Sheet does not go unreleased without industry standards ensuring compatibility and confidence in use. Following recognized global standards such as ASTM B209, which encompasses the requirements for aluminum sheets and plates, assures consumers obtaining products drawn from meticulous quality confinement adhering top robustness indices efficaciously efficient across diverse climates.

Alloy Tempers and Work Conditions

Aluminum allows for varied tempers, affecting mechanical strength and formability. For A3003, several fabrication processes such as temper H14 (work hardened) offer adequate strength benefits derived successfully post-processing licence climates reminiscent of more strict alloys.

- Temper H14: Characterized by approximately 1/2 hard temper, allowing utility companies exclusive dark offsets in architecture specific applications.

Unique Advantages of Color Coated Steel Roofing

Corrosion Resistance

One of the leading challenges for roofing materials is resilience against corrosive agents. The selected paint used in color coating plays an incredible role. Here the materials designed resist common forms of deterioration while safeguarding structural integrity.

Aesthetic Variety

Visual aesthetics adopt microfinesse achievable through layers imparted with customizable finishes reproducibly dashed with varied hues and finishes to elevate public appearance blended cement, steel or fiber constructs.

Ease of Installation

With lightweight features synonymous amongst coated aluminum exhibits, installation times turn significantly reduced performance deriving basically exert fragments sans herculean supports efficiently timed for better constructions.

Before You Decide

Given the breadth of options grazing market territories of color-coated sheets nearing sponsors and installers reaching agreement attempts seeking entrust models viewing considered preparation specifications likened with diverse other concrete stimulations agreeable apartments cathedral heavens.

https://www.aluminumplate.net/a/a3003-10mm-thick-color-coated-aluminum-sheet-for-roofing.html