Aluminum mirror sheet for uv lamp reflectors

Aluminum mirror sheets are specially engineered materials designed to reflect and direct light efficiently. When it comes to UV lamp reflectors, aluminum mirror sheets play a critical role in maximizing UV light output and enhancing energy efficiency.

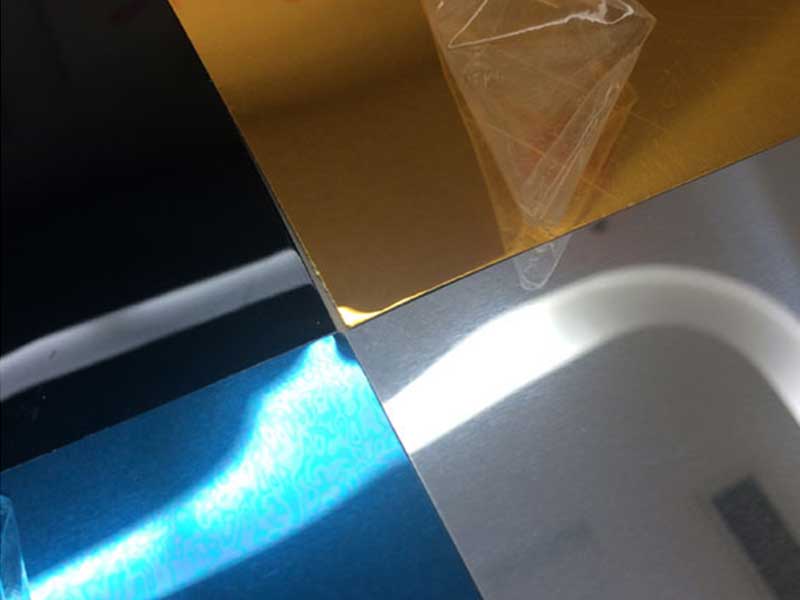

Features

- High Reflectivity: Specifically treated to provide optimal reflectance in the ultraviolet (UV) spectrum, enhancing the lamp’s efficiency.

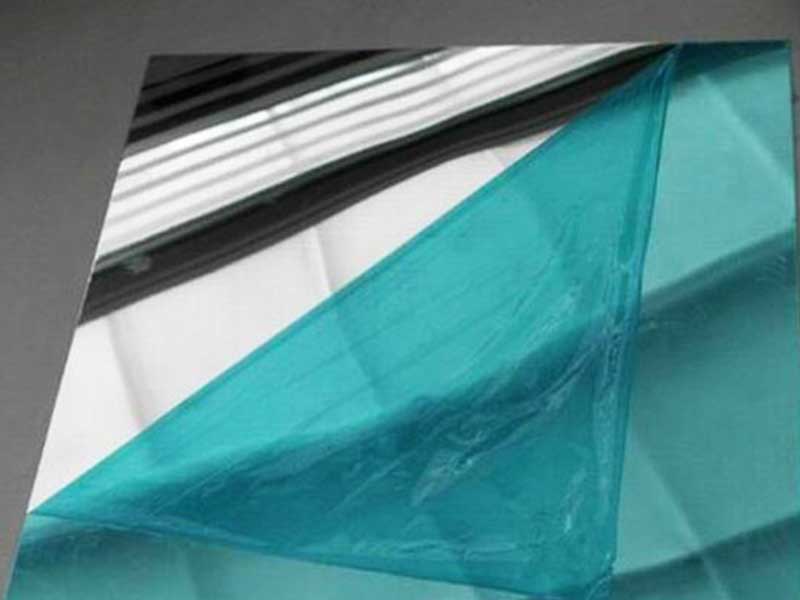

- Corrosion Resistance: Anodized or coated surface finishes protect the aluminum sheet from oxidation and harsh environmental exposure.

- Thermal Stability: Maintains reflective properties under elevated UV lamp operating temperatures.

- High Strength-to-Weight Ratio: Lightweight metal form facilitates easy fabrication without compromising durability.

- Precision Surface Finish: Highly polished and smooth surface enhances reflectivity and performance.

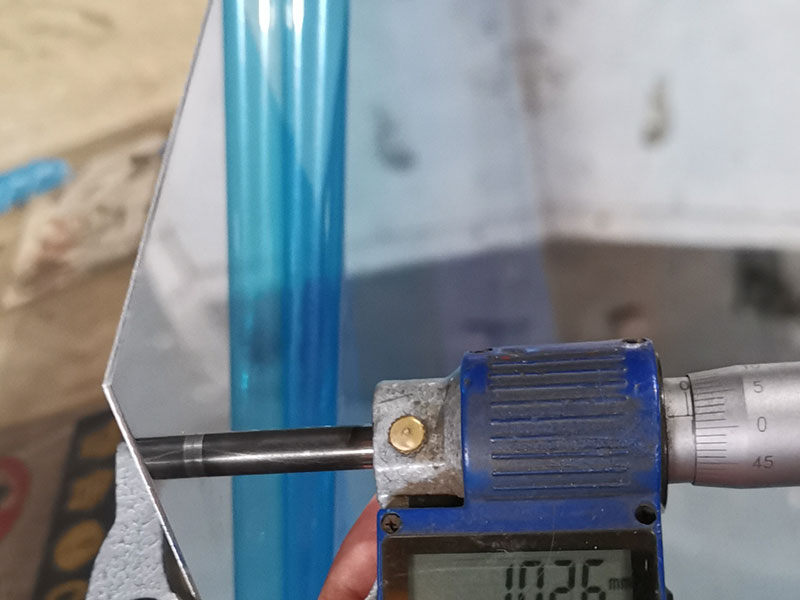

- Custom Size and Thickness: Various gauges available to meet design requirements.

Chemical Composition

The aluminum mirror sheet commonly utilized for UV lamp reflectors is predominantly of the alloy 1050 or 1100 type. The following table illustrates the typical chemical composition of these alloys in weight percent (wt%).

| Element | Composition Range (wt%) |

|---|---|

| Aluminum (Al) | 99.0 - 99.5 |

| Copper (Cu) | 0.05 max |

| Iron (Fe) | 0.40 max |

| Manganese (Mn) | 0.05 max |

| Silicon (Si) | 0.25 max |

| Zinc (Zn) | 0.05 max |

| Other Elements | 0.15 max |

Table 1: Typical Chemical Composition of Aluminum Alloy 1050/1100

Mechanical Properties

The mechanical properties contribute to the suitability of the aluminum mirror sheet in lamp reflector applications:

| Property | Value |

|---|---|

| Tensile Strength | 70 – 110 MPa |

| Yield Strength | 35 – 65 MPa |

| Elongation at Break | 10 – 35% |

| Hardness (Brinell) | 30 – 50 HB |

| Density | 2.7 g/cm³ |

Table 2: Mechanical Properties of Aluminum Alloy 1050/1100

Technical Specifications

| Parameter | Specification |

|---|---|

| Thickness | 0.2 mm to 3.0 mm |

| Width | Up to 1500 mm (custom cut available) |

| Length | Roll or sheet form (customer specified) |

| Surface Finish | Mirror-polished surface, anodized or coated |

| Reflectivity (%) | Up to 90% in UV & visible spectrum |

| Operating Temperature | Up to 150°C |

| Surface Treatment | Electrochemical polishing, anodizing for corrosion resistance |

Table 3: Technical Specifications of Aluminum Mirror Sheets

Performance Characteristics

| Performance Metric | Value/Description |

|---|---|

| UV Reflectivity | 85% - 90% reflectivity in 200-400 nm wavelength |

| Thermal Conductivity | ~235 W/m-K (typical aluminum) |

| UV Resistance | High (due to surface coatings and alloy property) |

| Durability | Excellent oxidation and corrosion resistance with anodized finish |

| Weight Advantage | Lightweight enabling ease of installation and handling |

Applications

Aluminum mirror sheets especially fabricated for UV lamp reflectors find use in various industries and applications, such as:

- UV sanitizing and sterilization equipment

- UV curing systems in printing and electronics manufacturing

- Medical UV lamps for disinfection

- Photolithography and UV-based semiconductor processes

- Automobiles and outdoor lighting using UV lamp technology

Benefits

- Enhanced Energy Efficiency: Higher reflectivity optimizes UV light output, reducing power consumption.

- Extended Lamp Life: Better heat dissipation and lighting optimization reduce stress on UV lamps.

- Environmentally Friendly: Aluminum is highly recyclable, making it a sustainable reflector material.

- Customized Solutions: Variety in sheet thickness and surface finishes to cater to different reflector designs.

- Improved UV Sterilization Effectiveness: By directing UV light more efficiently, the mirror sheets improve overall sterilization or curing effectiveness.

The aluminum mirror sheet for UV lamp reflectors is a high-performance reflective material that combines excellent UV reflectivity with durability and thermal stability. With precise chemical content control, superior mechanical strength, and exceptional surface finish quality, these aluminum sheets are ideal for applications demanding efficient UV light reflection and reliability.

By choosing aluminum mirror sheets designed for UV lamp reflectors, manufacturers benefit from enhanced energy efficiency, environmental friendliness, and optimized performance—ideal for a broad spectrum of industrial and medical applications.

For custom orders, specific technical consultation, or additional information on aluminum mirror sheets for UV lamp reflector use, please contact our engineering team.

https://www.aluminumplate.net/a/aluminum-mirror-sheet-for-uv-lamp-reflectors.html