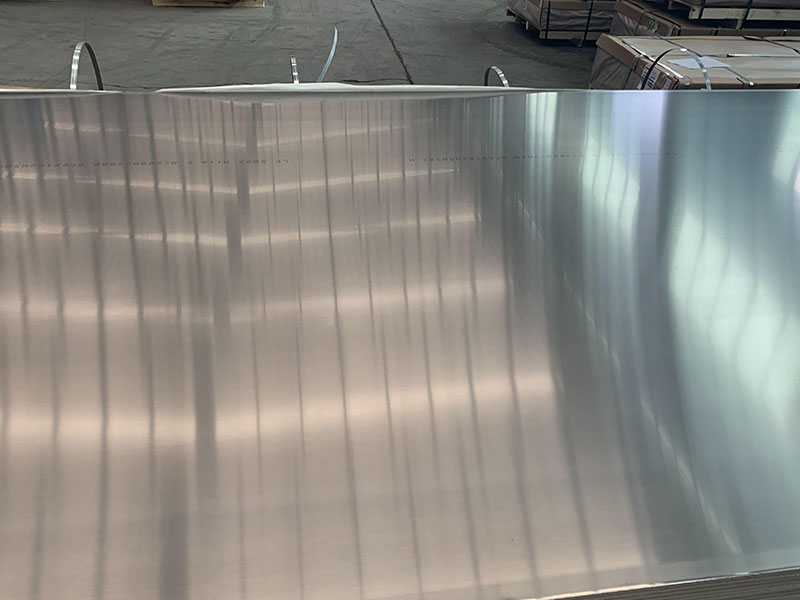

Aluminum plate for boat

Aluminum plates are rapidly becoming a preferred choice in the boating industry due to their lightweight, strength, corrosion resistance, and ease of fabrication.

Functions of Aluminum Plates in Boating

Aluminum plates serve several critical functions in the design and manufacture of boats:

- Structural Integrity: Aluminum's high strength-to-weight ratio provides the backbone for various boat structural components, ensuring that the craft can withstand pressure and impact.

- Corrosion Resistance: Marine-grade aluminum is resistant to the effects of seawater, which helps prolong the lifespan of vessels.

- Weight Reduction: The lightweight nature of aluminum significantly reduces a boat's overall weight, enhancing speed and fuel efficiency.

- Ease of Fabrication: Aluminum plates can be easily bent, shaped, and welded, providing considerable flexibility in design processes.

Applications of Aluminum Plates in Boating

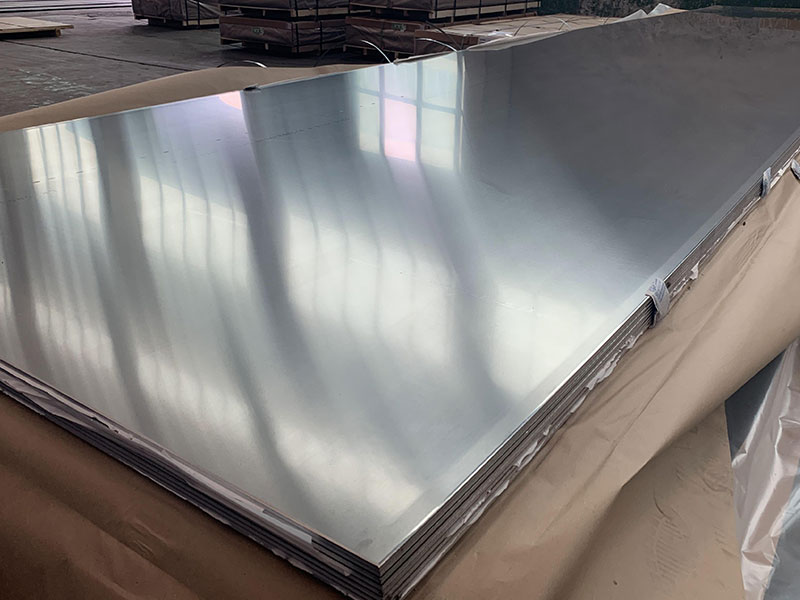

Aluminum plates are used widely in a variety of applications, such as:

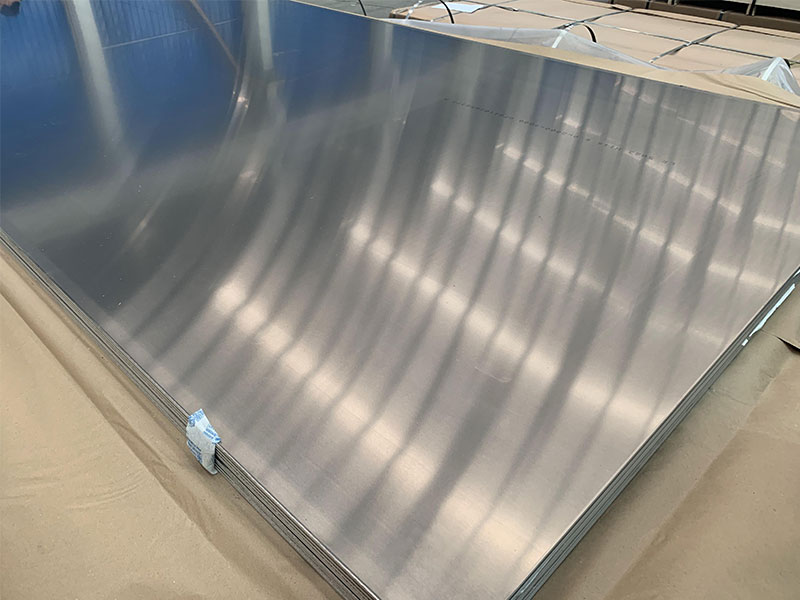

- Hull Manufacturing: Aluminum boats' hull elements utilize thick plates for reinforced stability and strength.

- Decks and Transoms: Combined materials often include aluminum for deck fittings, lockers, and to reinforce load applications on transoms.

- Vessel Components: Supports aesthetic and functional components like handrails, T-tops, and cabin structures.

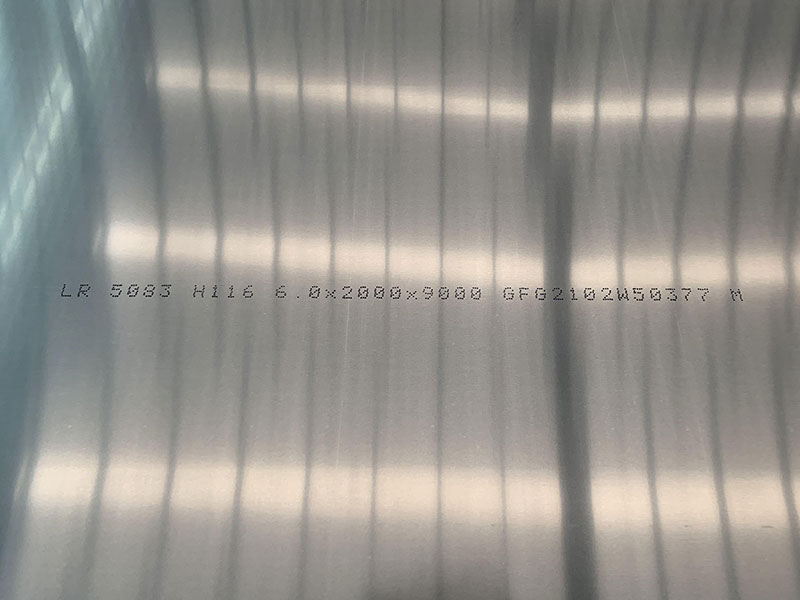

Technical Details

the technical specifications of aluminum plates for marine applications is essential for making informed decisions.

Parameters

Various parameters define the effectiveness and appropriateness of aluminum plates in the marine industry:

| Property | Value |

|---|---|

| Weight | Approx. 2.7 g/cm³ |

| Tensile Strength | 310 - 690 MPa |

| Yield Strength | 145 - 420 MPa |

| Elongation | Varies with temper |

Implementation Standards

For aluminum plates that cater to the marine industry, adherence to specific standards is crucial. The American Bureau of Shipping (ABS) and International Maritime Organization (IMO) provide guidelines regarding material properties, and several specifications can be utilized:

| Standard | Description |

|---|---|

| ASTM B928 | Standard Specification for Aluminum Alloy |

| AISI 6061 | Alloy Type commonly used in hulls / structures |

| ASTM D709 | Specification for aluminum marine structures |

Alloy Tempering Conditions

Aluminum plates come in various alloy temperings, each impacting attributes like strength, resistance, and formability. Below are some common alloys and their corresponding tempering conditions:

| Alloy | Excellent Feature | Typical Tempers |

|---|---|---|

| 5052 | High corrosion resistance | H32, H34 |

| 6061 | Good weldability and medium strength | T6, T651 Reducing loss stability |

| 7075 | High strength and roof structures | T73 Very high-strength applications |

Chemical Properties

The chemical composition significantly influences the behavior of aluminum plates under varying environmental conditions. elements and their effectiveness include:

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|---|

| 6061 | 0.4 Max | 0.7 Max | 0.15-0.40 | 0.15 Max | 0.8-1.2 | 0.04-0.35 | 0.25 Max | 0.15 Max |

| 5052 | 0.25 Max | 0.4 Max | Mature with Lesser (Cu effect via alloys) | 0.1 Max | 2.2-2.8 | 0.15 Max | 0.1 Max | 0.1 Max |

https://www.aluminumplate.net/a/aluminum-plate-for-boat.html