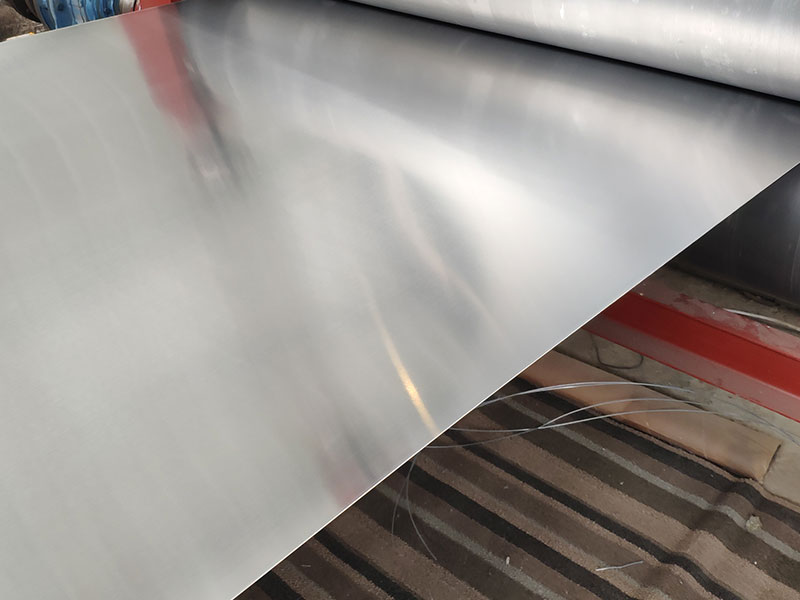

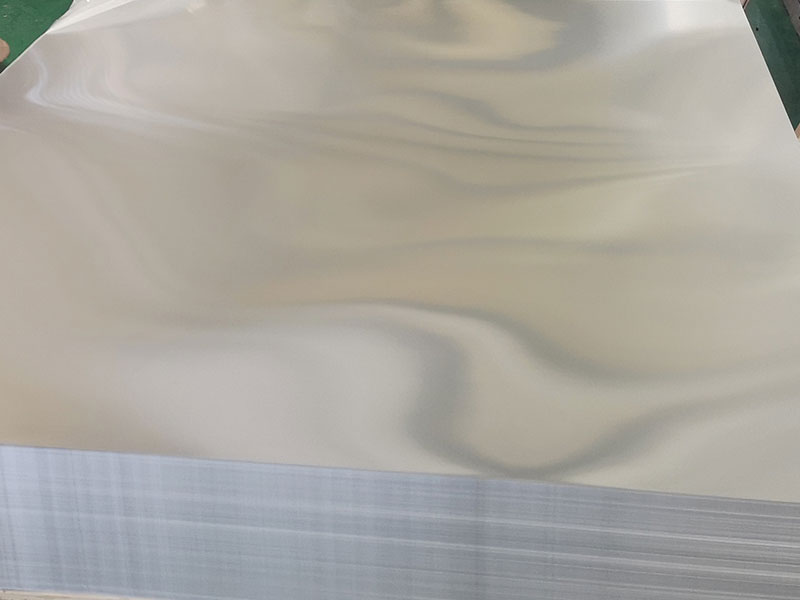

Aluminum sheet 1050 1060 1100 H14 H16 H18

Aluminum sheets are widely used across industries due to their unique combination of light weight, corrosion resistance, and excellent formability. Among the popular extruded alloys 1050, 1060, and 1100, combined with tempers like H14, H16, and H18, offer varied performance based on composition and tempering treatment.

Alloys 1050, 1060, and 1100 belong to the 1xxx series, known for their high purity (minimum 99% aluminum content). Their outstanding corrosion resistance, excellent electrical and thermal conductivity, and superior ductility make them ideal for various applications from packaging to construction.

| Alloy | Classification | Primary Feature |

|---|---|---|

| 1050 | Commercially Pure Aluminum | Excellent corrosion resistance; high formability |

| 1060 | Commercially Pure Aluminum | Higher minimum purity, enhanced electrical conductivity |

| 1100 | Commercially Pure Aluminum, with up to 0.2% Cu | Greater strength than 1050/1060; good corrosion resistance, great workability |

The differences between these alloys lie mainly in their subtle chemical composition variations which affect parameters like strength and conductivity.

Temper Designations: H14, H16, H18

Temper codes indicate the specific processing of the aluminum sheet after rolling to control its mechanical properties:

| Temper | Description | Typical Tensile Strength (MPa) | Effects on Properties |

|---|---|---|---|

| H14 | Strain hardened and partially annealed | Approx. 85-110 | Moderately hard; good strength and forming capability |

| H16 | Strain hardened and quarter hard | Approx. 125-140 | Increased hardness and strength, reduced ductility |

| H18 | Strain hardened and full hard | Approx. 160-180 | Maximum hardness and strength, least ductility |

These tempers offer flexibility to select the right balance between strength and formability, based on intended applications.

Chemical Composition

The purity is a decisive factor for these alloys in applications sensitive to electrical or thermal conductivity or corrosion resistance.

| Element | 1050 (wt%) | 1060 (wt%) | 1100 (wt%) |

|---|---|---|---|

| Aluminum (Al) | ≥ 99.5 | ≥ 99.6 | ≥ 99.0 |

| Copper (Cu) | ≤ 0.05 | ≤ 0.03 | 0.05-0.20 |

| Iron (Fe) | ≤ 0.40 | ≤ 0.35 | ≤ 0.95 |

| Manganese (Mn) | ≤ 0.03 | ≤ 0.03 | ≤ 0.05 |

| Silicon (Si) | ≤ 0.25 | ≤ 0.25 | ≤ 0.95 |

| Zinc (Zn) | ≤ 0.03 | ≤ 0.03 | ≤ 0.10 |

| Others | ≤ 0.03 | ≤ 0.03 | ≤ 0.05 |

This chemical composition makes these alloys appropriate for applications requiring low impurities, high corrosion resistance, and domestic or industrial usage.

Technical Specifications

The mechanical and physical properties differ slightly based on alloys and their temper conditions:

| Parameter | 1050-H14 | 1060-H16 | 1100-H18 |

|---|---|---|---|

| Tensile Strength (MPa) | 85 - 110 | 125 - 140 | 160 - 180 |

| Yield Strength (MPa) | ≥ 35 | ≥ 45 | ≥ 75 |

| Elongation (%) | 20 - 30 | 8 - 15 | 3 - 6 |

| Hardness (Brinell, HB) | ~30 - 40 | ~45 - 60 | ~60 - 90 |

| Density (g/cm³) | 2.71 | 2.71 | 2.71 |

| Thermal Conductivity (W/m·K) | ~220 | ~220 | ~220 |

| Electrical Conductivity (% IACS) | ~62 | ~63 | ~58 |

These specifications guide engineers and fabricators in choosing the alloys and tempers suitable for structural, fire-resistant, or conductive requirements.

Common Applications

Due to their unique characteristics, aluminum sheets of 1050, 1060, and 1100 alloys serve multiple industries with diverse demands.

- 1050 Alloy (e.g., H14 temper): Used broadly in decorative applications, roofing, ceiling panels, chemical equipment masks, and capacitors due to excellent corrosion resistance and moderate strength.

- 1060 Alloy (e.g., H16 temper): Favorite in electrical industries as conductor material, heat exchangers, architectural applications requiring tight tension including light reflectors and street lighting because of slightly better purity and conductivity.

- 1100 Alloy (e.g., H18 temper): Common in food and chemical handling where slightly higher mechanical strength is needed - ideal for kitchen utensils, roofing sheets, siding panels, and transport equipment; often employed where great formability and leak-proof characteristics are essential.

Implementation Standards

To ensure adherence to quality and performance, aluminum sheets 1050, 1060, and 1100 conform to various recognized international standards:

| Standards | Details |

|---|---|

| ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| ISO 6361 | Wrought Aluminum and Aluminum Alloy Sheets, Strips and Plates Pads |

| EN 485-2 | Aluminum and aluminum alloys - Sheet, strip and plate - Mechanical properties |

| JIS H4100 | Aluminum and aluminum alloy rolled products |

Compliance with these standards guarantees mechanical properties, dimensional tolerances, and chemical integrity suited for reliability in industrial application.

https://www.aluminumplate.net/a/aluminum-sheet-1050-1060-1100-h14-h16-h18.html