Anodized aluminum plate 25um

When considering aluminum alloys for a multitude of applications—from industrial components to architectural elements—one term recurring in discussions is “anodized aluminum,” often accompanied by thickness specifications. Among these, the “25µm anodized aluminum plate” stands out, not merely as a technical detail but as a layered story of functional performance and aesthetic appeal.

The Significance of a 25µm Thickness: More Than a Numerical Figure

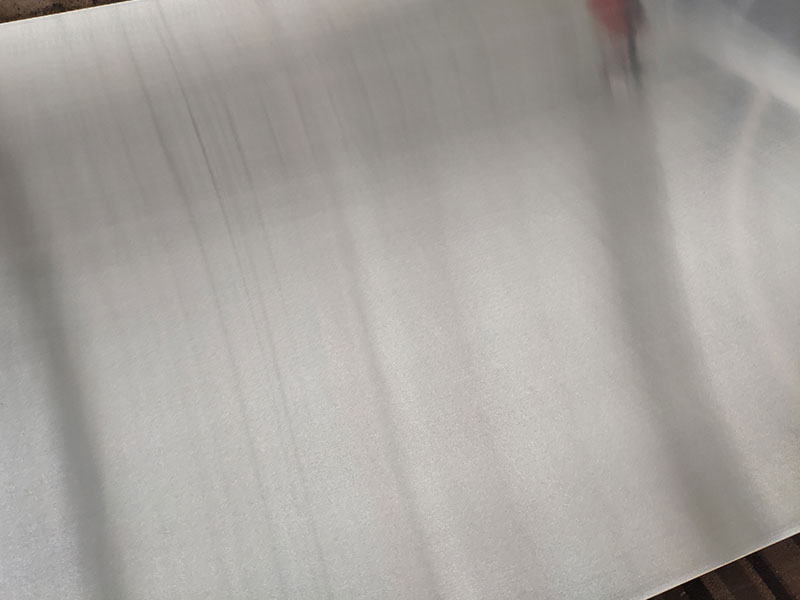

At first glance, 25 micrometers (µm) might seem a minute measurement—roughly 1/40th of a human hair thick. However, in the context of anodized aluminum plates, this modest layer performs a dramatically crucial function. It’s a carefully engineered barrier that enhances corrosion resistance, wearability, and surface hardness, making this specific anodic thickness an optimal choice for applications demanding longevity and visual appeal.

This particular thickness strikes an effective balance: thin enough to preserve the aluminum’s intrinsic light weight and thermal conductivity, yet substantial enough to provide measurable improvements in surface durability. Unlike thinner coatings, which might degrade quickly, or thicker layers, which could impair where weight is a concern, 25µm offers a pragmatic middle ground suitable for a broad range of demanding environments.

Beyond Aesthetics—The Layer’s Functionality from a Durability Standpoint

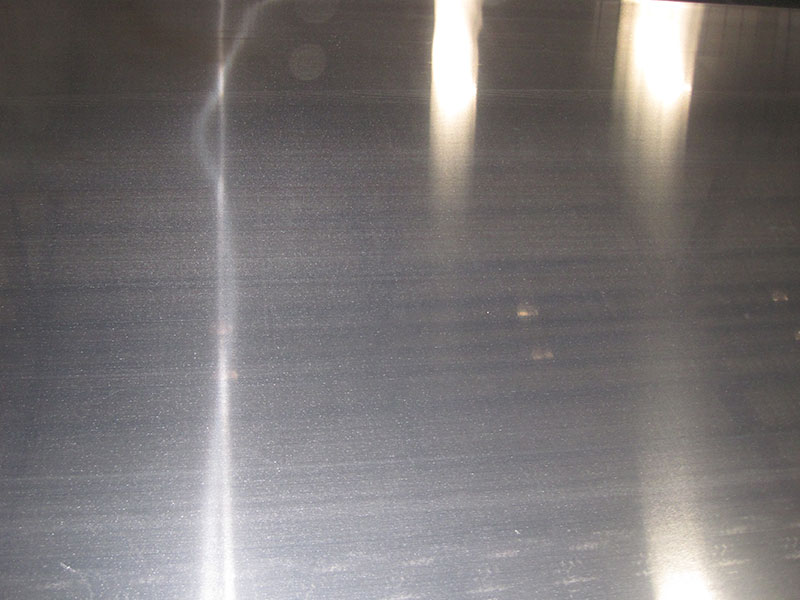

From a firewall against corrosive agents such as moisture, salts, and pollutants, a 25µm anodized film provides a robust defense—especially vital in outdoor or marine settings. The anodized layer is essentially aluminum oxide formed through electrochemical processes that transform the surface, resulting in a crystalline, tightly adherent film.

In practical terms, this oxide layer not only houses a protective barrier but also significantly boosts surface hardness. This translates into increased resistance to scratches and abrasion—a consideration in environments where aluminum components are subjected to frequent handling, cleaning, or mechanical stress. For instance, rooftop panels, decorative architectural facades, or high-touch consumer products benefit immensely from this enhanced durability.

The Role in Aesthetic Versatility: Keeping the Visual Edge Intact

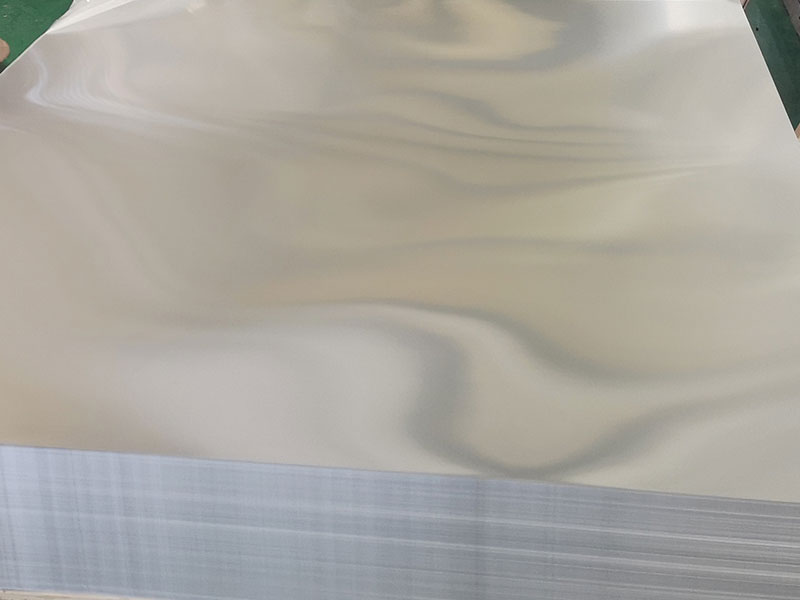

A less obvious, yet equally vital dimension of 25µm anodized aluminum plates lies in their visual appeal. These layers are integral to dyeing, coloring, or achieving matte and glossy finishes, making anodized aluminum highly customizable for aesthetic demands.

From a distinctive reflective sheen to matte textures, anodization at this controlled thickness ensures color consistency and depth, while also shielding the dyed surface against fading caused by UV exposure. For architects and designers, this translates to intricate finishing options where aesthetics must walk hand in hand with resilience.

Environmental and Sustainable Considerations

Modern manufacturing increasingly emphasizes sustainability. Anodized aluminum plates, particularly those with precise 25µm layers, resonate with eco-conscious initiatives because the process is environmentally friendlier compared to other coatings. Anodization involves electrochemical processes with minimal volatile emissions, and the resultant oxide layer enhances aluminum's natural corrosion resistance, often eliminating the need for additional paint or coating layers that might carry environmental drawbacks.

Customization, Challenges, and Quality Control

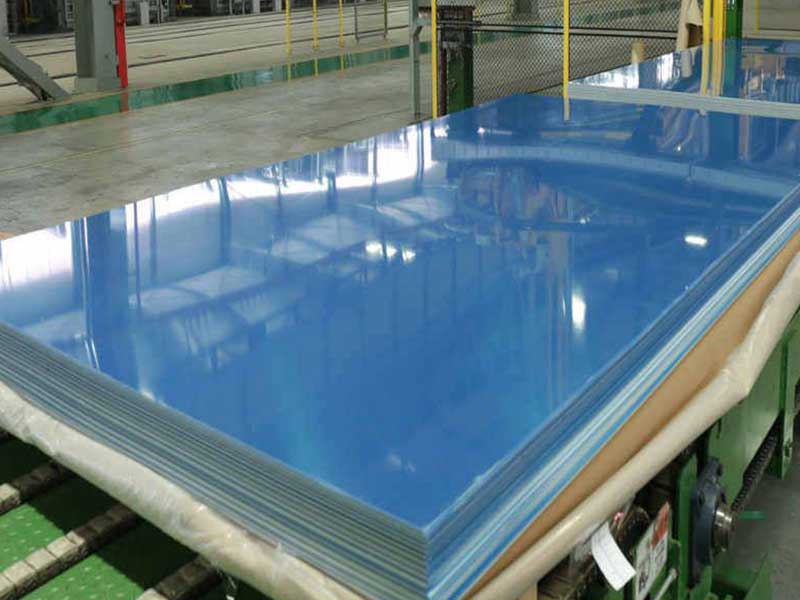

While the standard thickness of 25µm exemplifies consistency, customized applications might require tailoring for specific performance outcomes. Achieving uniform thickness—particularly at 25µm—demands high-precision control within manufacturing.

Quality control processes such as visual inspections, thickness measurements via eddy current or microscopic analysis, and durability testing ensure that each batch delivers consistent, predictable performance. This thoroughness culminates in aluminum plates that professionals can rely upon for critical applications.

Final Thoughts

The “anodized aluminum plate 25µm” isn’t simply a component with a specified coating thickness; it represents a synergy of science and design—delivering an optimal union of strength, beauty, and sustainability. Its absorbable, resilient film supports modern needs where metals must serve dual roles: withstand harsh environments and contribute to innovative aesthetics.

Choosing a 25µm anodized aluminum plate means committing to a versatile, durable, and eco-friendly solution that confidently elevates projects—be it in architecture, engineering, or consumer goods. From a distinct perspective, it's clear that this micro-layer plays a macro role in shaping durable designs for a sustainable future.

https://www.aluminumplate.net/a/anodized-aluminum-plate-25um.html