Mirror Color Coated Aluminium Coil

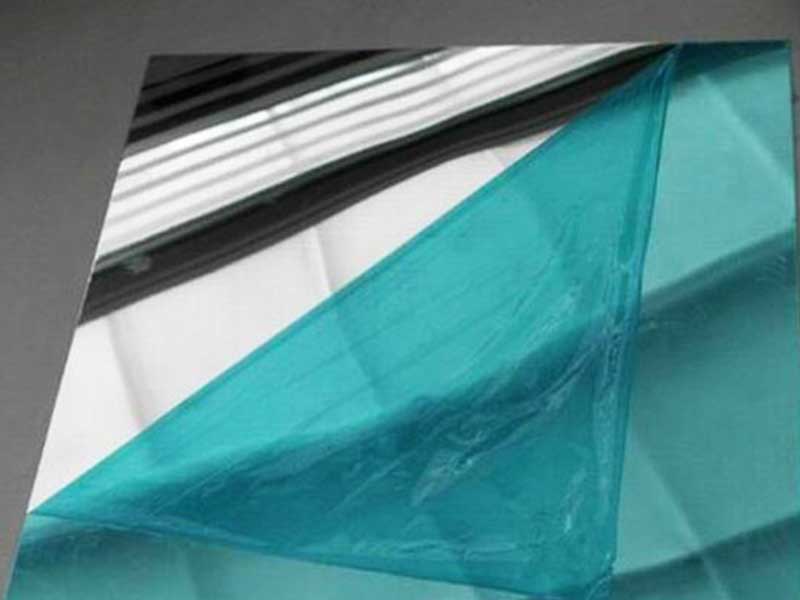

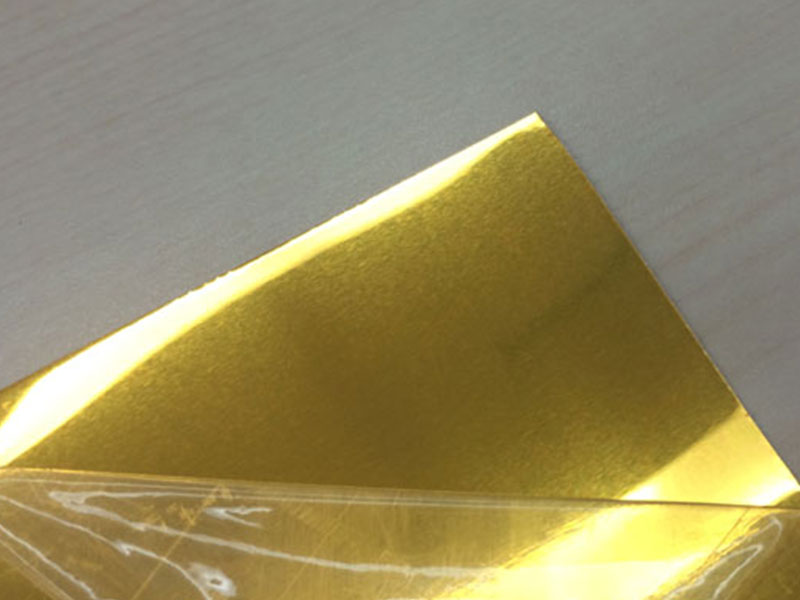

Mirror Color Coated Aluminium Coil is an advanced product that combines the advantages of both surface finish and color presentation in aluminum materials. Known for its aesthetically pleasing appearance and high-quality production standards, this material is widely used across various industries.

Features

- Aesthetic Appeal: The mirror finish provides a strikingly reflective surface, allowing for innovative design applications, particularly in architecture and interior design.

- Color Variety: Available in multiple colors through the color coating process, which can match various design needs and climates.

- Durability: Offers excellent corrosion resistance and weatherability, ensuring longevity in a variety of environmental conditions.

- Lightweight: Being aluminum, it maintains a low weight to strength ratio, making it an outstanding computation against traditional materials like steel.

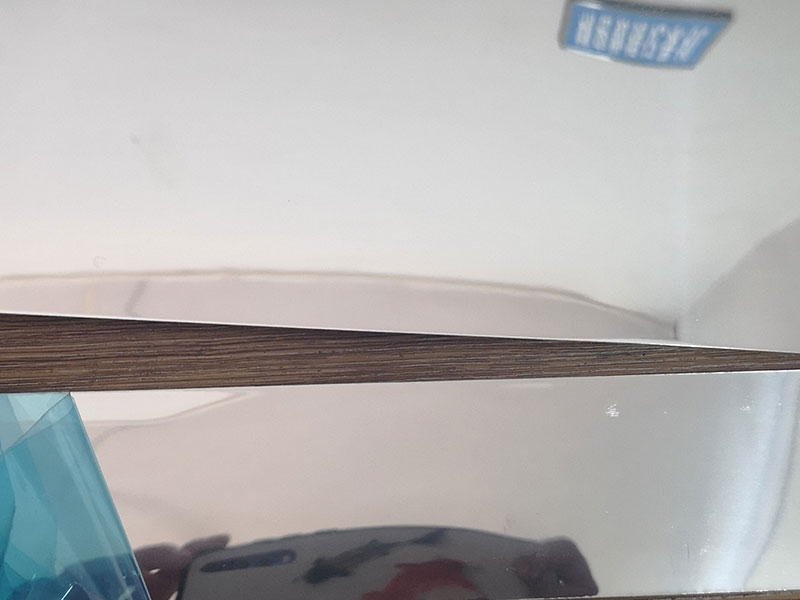

- Easy Fabrication: Can be processed in various ways, enabling customization in terms of size and thickness.

Applications

Mirror Color Coated Aluminium Coil finds its utility in several industries, including but not limited to:

- Architecture: Best for facade cladding, ceilings, and interior finishes.

- Decorative Items: Ideal for creating home decor products, mirrors, arts, and crafts.

- Automotive: Used for lightweight vehicle body parts to enhance aesthetics.

- Consumer Goods: Widely used in electronics and appliances that require a modern aesthetic.

- Signage: Effective for creating high-impact visual signage due to its reflection property.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Aluminum alloy (usually series 1xxx/3xxx/5xxx) |

| Temper | H14, H16, H18, H24 as per requirement |

| Width Range | 10 mm to 2000 mm |

| Thickness Range | 0.2 mm to 3 mm |

| Surface Finishing | Mirror finish with color coating |

| Color Options | RAL color standards available |

Chemical Composition

the chemical properties of typical alloys used in Mirror Color Coated Aluminium Coils is crucial. The table below lists typical chemical compositions for predominant aluminum grades:

| Alloy | Mg (Magnesium) | Si (Silicon) | Fe (Iron) | Cu (Copper) | Mn (Manganese) | Zn (Zinc) | Al (Aluminum) |

|---|---|---|---|---|---|---|---|

| 1060 | 0.03 max | 0.25 max | 0.4 max | 0.1 max | 0.05 max | 0.1 max | >99.60 |

| 3003 | 1.0 - 1.5 | 0.6 max | 0.7 max | 0.1 max | 0.05 - 0.20 | 0.10 max | Balance |

| 5052 | 2.2 - 2.8 | 0.25 max | 0.4 max | 0.1 max | 0.1 - 0.2 | 0.10 max | Balance |

Alloy Tempering Conditions

The different tempering states allow effects on the mechanical quoted standards for practical creation use:

| Temper | Condition | Typical Applications |

|---|---|---|

| H14 | Work-hardened but not annealed. Realizes moderate strength. | Lightweight industry products |

| H16 | Work-hardened by cold working; thus offers higher strength. | Durable industrial designs |

| H18 | Higher gauge highlights benefit by more stress; improved appearance. | End products demanding layered structures or tones |

https://www.aluminumplate.net/a/mirror-color-coated-aluminium-coil.html