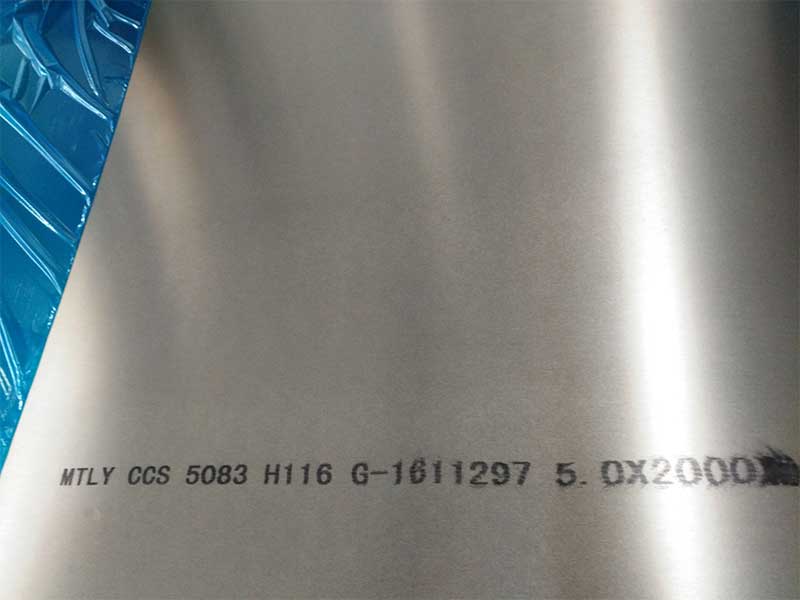

Anodized polished mill finish aluminum alloy plate 5086

When considering aluminum alloy plates for your projects, Alloy 5086 often stands out—particularly in its anodized polished mill finish form. While many materials offer strength or aesthetics, 5086 achieves a unique balance, making it an exceptional choice.

Why 5086? The Alloy’s Intrinsic Strength

5086 belongs to the 5xxx series aluminum alloys, prized for excellent corrosion resistance and robust mechanical properties. Unlike heat-treatable alloys, 5086 gains strength through strain hardening, translating to reliable toughness without compromising formability. This strength is crucial in demanding environments such as marine, transportation, and architectural applications.

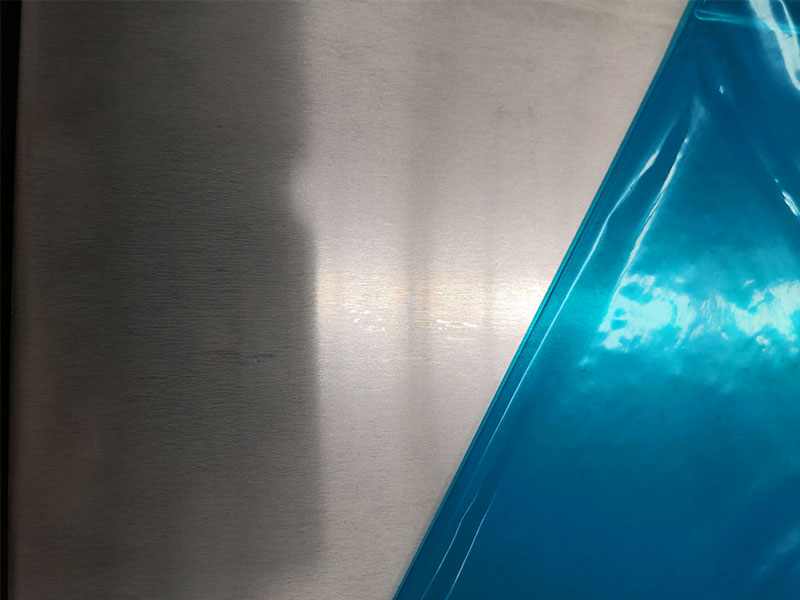

Polished Mill Finish: More Than Just Looks

The term "mill finish" typically implies a raw surface after rolling, often dull and marked. However, when polished, the mill finish transforms dramatically: fine abrasion and grinding produce a subtly bright, smooth texture that showcases the alloy’s natural luster while retaining micro-textural integrity. This finish not only enhances aesthetic appeal but also prepares the surface for superior anodizing.

Anodizing: Amplifying Durability and Visual Appeal

Anodizing is an electrochemical process that thickens the aluminum oxide layer on the surface, creating a hard, wear-resistant, and non-conductive barrier. Combining anodizing with polished mill finish delivers unexpected synergy:

- Enhanced Corrosion Resistance: Ideal for harsh environments, such as saltwater exposure, anodized 5086 significantly reduces oxidation and pitting, extending the service life.

- Aesthetic Appeal with Functional Toughness: The anodized surface maintains the polished shine with added matte subtleties, avoiding the glare of glossy metals while resisting fingerprints, stains, and scratches.

- Low Maintenance: The natural oxide layer repels dirt and debris, simplifying cleaning and reducing maintenance intervals.

Distinct Applications: Beyond Ordinary Uses

From a viewpoint often overlooked, anodized polished mill finish 5086 plates have enormous appeal in custom applications:

- Architectural Panels: Offering an elegant yet resilient surface for modern building facades subject to weather, pollution, and mechanical contact.

- Marine Equipment: Balancing enduring corrosion resistance with sleek finishes for equipment exposed to seawater spray and mechanical wear.

- Decorative Automotive Components: Providing lightweight structural strength along with a visually striking finish that withstands road conditions and environmental stress.

Buying Tips for Customers

- Confirm that the polished mill finish matches your design expectations—request surface samples.

- Specify anodizing thickness based on environmental needs; typical ranges from 15-25 microns for general protection, higher for extreme conditions.

- Verify temper and mechanical specs; for example, H32 tempered 5086 offers increased strength while retaining formability.

- Communicate application specifics with your supplier to ensure optimized finishes and alloy selections.

https://www.aluminumplate.net/a/anodized-polished-mill-finish-aluminum-alloy-plate-5086.html