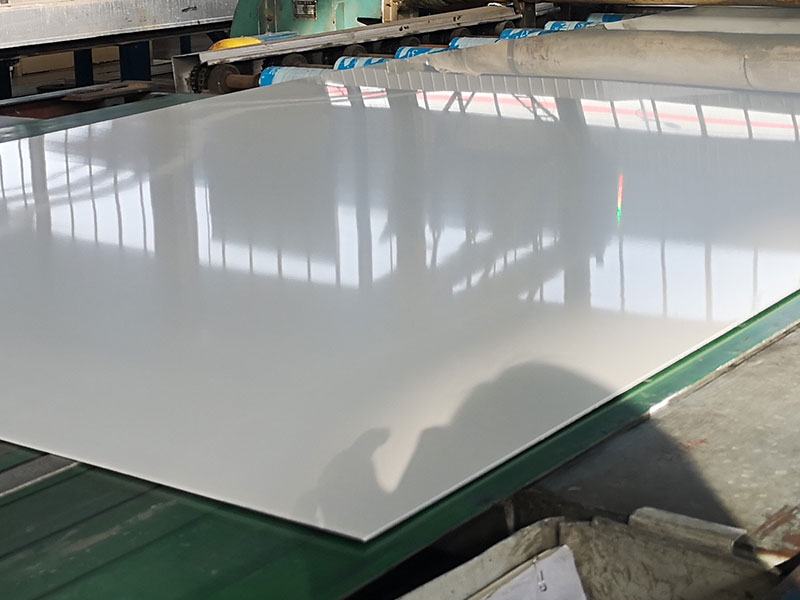

16 gauge aluminum aluminium plate

Aluminum plates have become indispensable in various industries thanks to their versatility, corrosion resistance, and lightweight properties. Among them, the 16 gauge aluminum plate stands out as a preferred choice for numerous applications due to its balanced strength, thickness, and workability.

16 Gauge Aluminum Plate

The term "16 gauge" refers to the thickness of the aluminum plate. Gauge measurement systems vary, but generally, a 16 gauge aluminum sheet has a thickness of 0.0508 inches (1.29 mm). Choosing the right gauge means balancing durability, weight, and flexibility—and 16 gauge aluminum strikes that middle ground efficiently.

Functions and Features

- Durability with Light Weight: The 16 gauge thickness offers solid strength to withstand moderate impacts and stresses while maintaining aluminum's lightweight advantage.

- Corrosion Resistance: Aluminum forms a natural protective oxide layer resisting weather and chemical attacks, important for outdoor exposure or corrosive environments.

- Workability: The plate is easy to cut, weld, form, and machine, allowing custom fabrication in various applications.

- Non-magnetic and Non-sparking: This makes it ideal in environments where magnetic interference or sparks can cause safety hazards.

- Thermal and Electrical Conductivity: Keeps this plates useful in heat exchange or electrical enclosure contexts.

Common Applications

Due to these properties, 16 gauge aluminum plates are widely used in sectors such as automotive, aerospace, construction, food processing, marine, and electronics. You commonly find it employed for:

- Structural components in machinery and equipment

- Architectural paneling and exterior building facades

- Fabricated parts such as frames, brackets, and housings

- Transportation industry parts including trailers, boats, and vehicle body panels

- Storage tanks, chemical processing equipment, and heat exchangers

- Kitchen appliances and food processing equipment

| Parameter | Value |

|---|---|

| Thickness | 0.0508 inches (1.29 mm) |

| Width | Commonly 48–60 inches (varies) |

| Length | Custom cut (up to 144 inches+) |

| Density | 2.7 g/cm³ |

| Typical Alloy Series | 1000, 3003, 5052, 6061 |

| Surface Finish | Mill polish, brushed, anodized |

| Formability | Excellent (depending on temper) |

The exact sizes and finishes can vary according to customer requirements and processing methods.

Common Alloy Types and Temper Conditions

The choice of alloy and associated temper hardening affect mechanical properties substantially:

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Description |

|---|---|---|---|---|---|

| 3003 | H14 | 130 – 145 | 110 – 130 | 12 – 20 | Good corrosion resistance, excellent forming |

| 5052 | H32 | 228 – 275 | 193 – 228 | 10 – 15 | Higher strength, excellent corrosion resistance |

| 6061 | T6 | 310 – 350 | 275 – 310 | 10 – 17 | Strong, excellent mechanical properties |

| 1100 | O | 90 – 115 | 34 – 69 | 35 – 45 | Highly ductile, commonly used as commercial grade |

Chemical Composition (Representative Examples)

the chemical makeup helps assess suitability for specific conditions or compliance with standards:

| Element | 3003 (%) | 5052 (%) | 6061 (%) |

|---|---|---|---|

| Aluminum (Al) | Balance (~96.8) | Balance (~97.25) | Balance (~97.9) |

| Copper (Cu) | 0.05 – 0.20 | 0.10 max | 0.15 – 0.40 |

| Magnesium (Mg) | 1.0 – 1.5 | 2.2 – 2.8 | 0.8 – 1.2 |

| Manganese (Mn) | 1.0 – 1.5 | 0.10 max | 0.15 max |

| Silicon (Si) | 0.6 max | 0.4 max | 0.4 – 0.8 |

| Iron (Fe) | 0.7 max | 0.4 max | 0.7 max |

| Zinc (Zn) | 0.10 max | 0.25 max | 0.25 max |

Industry Standards and Quality Control

Manufacture and supply of 16 gauge aluminum plates generally comply with international standards to ensure uniform quality and dimensional accuracy:

| Standard | Description |

|---|---|

| ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| EN 485 | Aluminum and aluminum alloys: Sheet, strip and plate specification |

| AMS 4012 / AMS 4018 | Aerospace material specifications for plating and mechanical properties |

| ISO 6361 | Wrought aluminium and aluminium alloy sheets, strips, and plate technical delivery conditions |

Compliance with such standards ensures competitive performance with guaranteed mechanical and chemical properties suitable for crucial applications.

The 16 gauge aluminum plate is an ideal material choice combining great strength, corrosion resistance, and machinability. Established standards and common alloy/temper options offer vendor and buyer certainty. Its adaptability across transportation, architecture, and manufacturing sectors means these plates fulfill vital engineering demands. Embedded with numerous usability benefits and backed by comprehensive technical data, 16 gauge aluminum plates continue to support ongoing innovation and efficiency for quality-driven industries worldwide.

Enquire with your material supplier today for custom cuts, choice of alloy, temper options, and finishes designed to best meet your particular project requirements.

https://www.aluminumplate.net/a/16-gauge-aluminum-aluminium-plate.html