Embossed aluminium sheet 3003

When it comes to choosing materials for architectural designs, construction, or manufacturing, aluminum sheets is know for their versatility and durability. Among the various alloys available, the embossed aluminum sheet 3003 has gained favor for its enhanced aesthetic appeal and functional benefits.

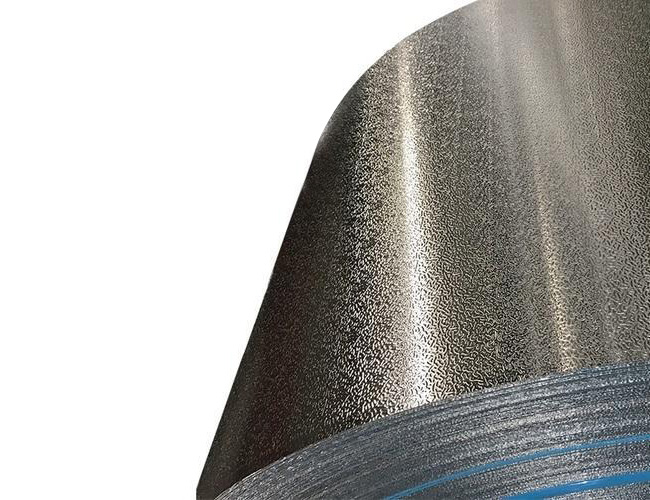

What is Embossed Aluminum Sheet 3003?

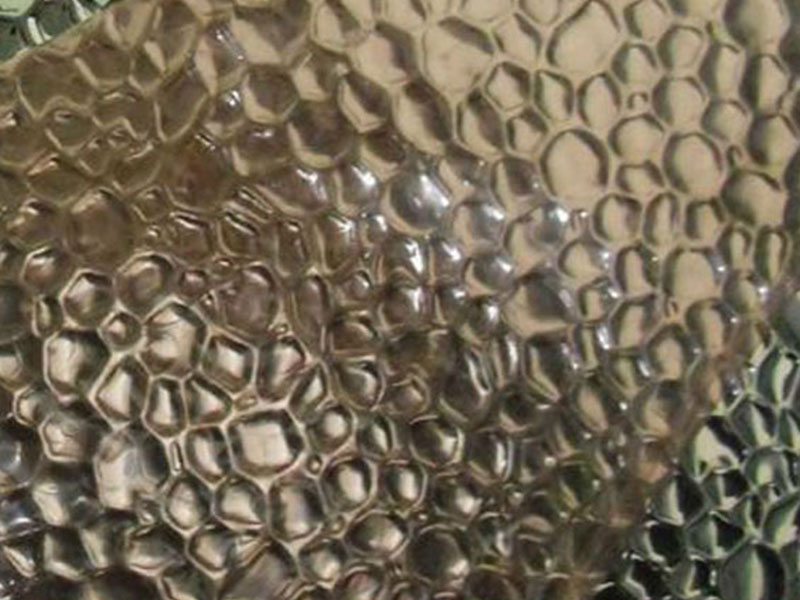

Embossed aluminum sheets are distinguished by surface textures created through a process of deformation that yields raised designs. The grade 3003, containing 1.2% to 1.5% manganese, is part of the 3000 series of aluminum alloys and has been a dependable choice for many applications due to its excellent corrosion resistance and sufficient strength. While unembossed aluminum sheets are popular, adding an embossed texture not only enhances aesthetic appeal but also improves functional properties such as rigidity, slip-resistance, and less susceptibility to scratches or wear.

Properties and Advantages

Let’s dive into some of the critical attributes that underscore the infrastructure robustness of embossed aluminum sheets, particularly in the 3003 alloy:

Chemical Composition:| Element | Composition (%) ||---------------|---------------------|| Aluminum (Al) | Balance (minimum 98%)|| Manganese (Mn)| 1.0 – 1.5 || Silicon (Si) | 0.3 || Iron (Fe) | 0.7 || Copper (Cu) | 0.2 || Magnesium (Mg)| 0.1 || Zinc (Zn) | 0.1 || Titanium (Ti) | 0.1 || Others | See applicable standards|

Physical Properties:

- Density: Approximately 2.73 g/cm³, perfect for lightweight structural needs.

- Melting Point: Around 655-660°C, making it suitable for moderate temperature applications.

Mechanical Properties:

- Tensile Strength: Ranges from 170 to 240 MPa, which underlines a reliable resistance to deformation.

- Yield Strength: Approximated at 120-150 MPa, denoting its robustness under stress.

- Elongation: Around 20-25% — a noteworthy feature heading towards considering shaping and forming parts.

Alloy Tempering:

- The most common temper for 3003 aluminum is H14, conveying that it has undergone strain hardening without over-aging. This military-grade temper improves its hardness, balance, and deformation by convincing ductility along with enhancing its mug-like force memory.

Implementation Standards

For businesses looking to integrate embossed aluminum sheet 3003 into their projects, there are several industry standards that come into play culminating in high-quality craftsmanship. Important certifications like ASTM B209 and the Aluminium Association standards ensure uniformity and quality across materials used in construction and manufacturing. such standards allows for better quality assurance and regulation compliance, which also significantly impacts safety levels.

Ideal Applications

From an architect’s point of view, embossed aluminum sheet 3003 shines as an excellent choice for structural elements, commercial facades, etc. Here are a few vital applications categorized critically:

- Architectural: Used in cladding, ceiling panels, decorative covers, and internal wall lining.

- Retail: Enhances visual merchandising materials; signage utilizing vibrant embossed designs capture shopper attention effortlessly.

- Automotive: Designed for inner decorative uses, ensure lightweight attributes don't compromise on strength.

- Food Services: Notably, this material is corrosion-resistant; hence ideal for food-safe environments, including kitchen ceilings and equipment requiring a clean finish.

So, what is the larger narrative when considering embossed aluminum sheet 3003? On the surface, this material offers aesthetics; however, it serves as a story about resilience and adaptability. Unlike traditional materials which can rust or dent under pressure, 3003 embodies a modern-era opportunity for oneself whether for constructing, remodeling, or commercial displays.

https://www.aluminumplate.net/a/embossed-aluminium-sheet-3003.html