Hard Anodized coated Aluminum Sheet 1.2mm thick

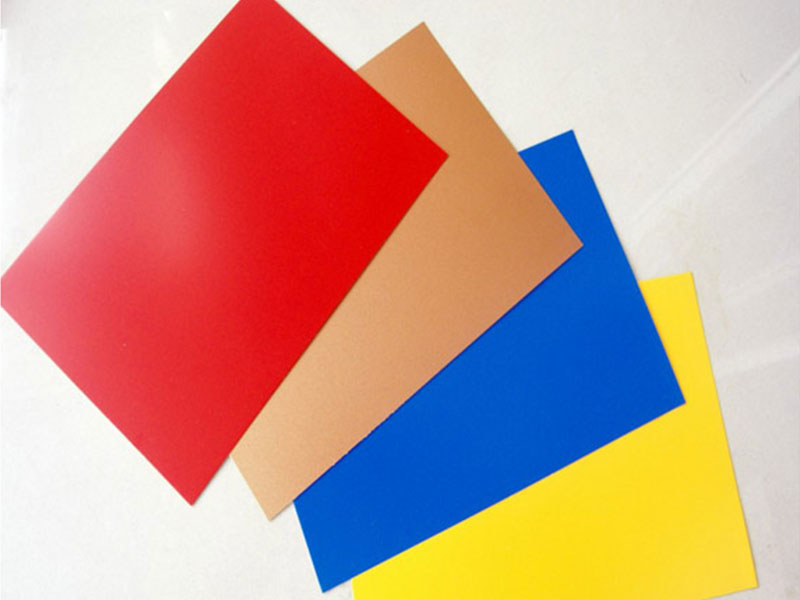

Aluminum has long been celebrated for its lightweight yet durable characteristics, making it a go-to material in various industries—from aerospace to automotive, and even civil engineering. Among the numerous treatments used to enhance aluminum's natural strengths, hard anodizing stands out for its remarkable ability to provide improved durability and corrosion resistance.

Hard Anodizing

Hard anodizing is an electrochemical process that thickens the natural oxide layer on the surface of aluminum, creating a hard, protective coating that is significantly tougher than regular anodizing. This enhancement not only boosts the dielectrical resistance of the aluminum but also plays a crucial role in protecting it against wear and corrosion.

Parameters and Limitations

| Property | Parameters |

|---|---|

| Thickness | 1.2mm |

| Coating Thickness | Typically 25-150 microns |

| Corrosion Resistance | Excellent (tested against various chemicals) |

| Wear Resistance | High (able to withstand abrasive forces) |

| Surface Finish | Matte or Brushed |

| Hardness | Between 250 and 450 Vickers Hardness |

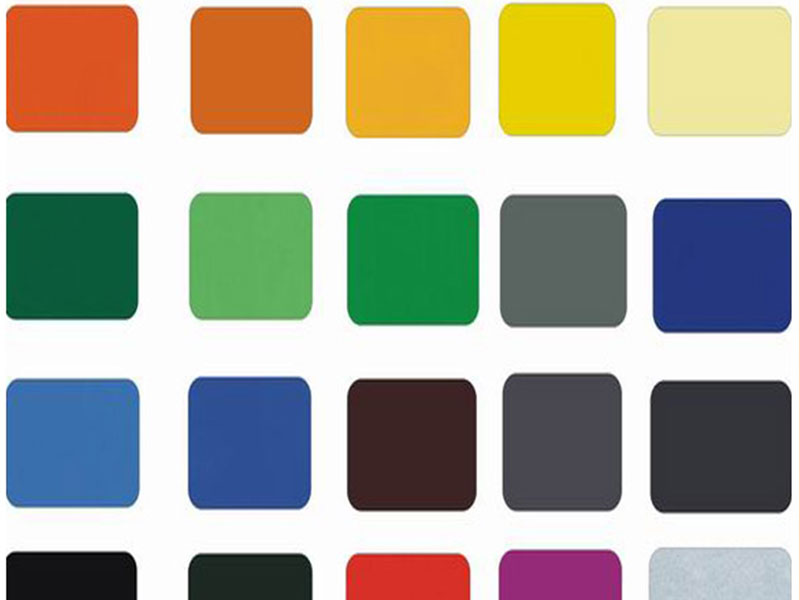

| Color Options | Customizable (black, grey, bronze) |

Implementation Standards

The implementation of hard anodizing is detailed in various standards designed to enhance quality and consistency. Here are some notable ones:

ASTM B580: This standard governs the specification for hard anodic coatings on aluminum for engineering applications, ensuring a high degree of melt purity and quality.

MIL-A-8625: This military specification outlines various requirements for anodic coatings, which is especially significant for parts used in harsh or demanding environments.

ISO 10090: Around the globe, this standard prescribes the criteria for hydrocarbon and organic coating finishes on aluminum surfaces.

these guidelines helps to inform manufacturers and clients about what is necessary to achieve cost-effective and dependable results.

Unique Benefits of 1.2mm Hard Anodized Aluminum Sheets

1. Durability

Although aluminum is naturally sturdy, hard anodized coatings take durability to an entirely new level. The coating not only protects against scratches but also significantly reduces wear against abrasive materials. This is especially beneficial in industries like manufacturing and construction where intrusive environments are commonplace.

2. Corrosion Resistance

Every aluminum user dreads corrosion, which can severely impact product longevity and integrity. Implementing a hard anodized layer means that the sheet will stand up against moisture and corrosive elements, extending the sheet's lifecycle and decreasing maintenance needs.

3. Aesthetic Versatility

From factories to homes, the visual appeal of aluminum cannot be overlooked. Available in a variety of colors, including muted shades that fit well into industrial designs or decorative shades for aesthetic applications, the hard anodizing process also ensures that these colors remain vibrant over time, preventing fading or wear.

4. Eco-Friendly Option

Amidst rising concerns about environmental limitations, hard anodized aluminum sheets claim an eco-friendly block. The process is non-toxic and can be easily recycled later on in the material lifecycle.

Applications that Gain from 1.2mm Hard Anodized Aluminum Sheets

The cornerstone of versatile usage, these sheets are finding popularity in different domains, namely:

- Architectural Features: Designing facades that not only entice visually but also stand the test of nature’s elements.

- Automotive Parts: Lightweight components that require strength and longevity.

- Kitchen Equipment: Utensils and fixtures demanding hygienic surface coatings easy to maintain.

- Marine Applications: Boat parts needing both resilience against saltwater and light-weight integrity.

Final Thoughts

Hard anodized coated aluminum sheets with a thickness of just 1.2mm offer an intersection of beauty, resilience, and performance unmatched by many alternatives. With customizable thickness, color, and usability, these sheets position themselves as quintessential engineering and design solutions. So, whether you're ingraining creativity into a design or solidifying functionality in an engineering need, hard anodized aluminum is undeniably a worthy investment. Replacing simpler materials with such a robust option fosters long-term benefits both functionally and aesthetically.

Harness the remarkable combination of longevity and elegance with hard anodized coated aluminum sheets—where realistic applications unite with cutting-edge material durability.

https://www.aluminumplate.net/a/hard-anodized-coated-aluminum-sheet-12mm-thick.html