How to choose the aluminium sheet for ps plate

When selecting an aluminium sheet for photostatic (PS) plate applications, it's essential to understand the variety of features and performance metrics that influence the final product's suitability and effectiveness. This guide will provide an analysis of characteristics, performance information, applications, and benefits associated with aluminium sheets specifically tailored for this purpose.

Features

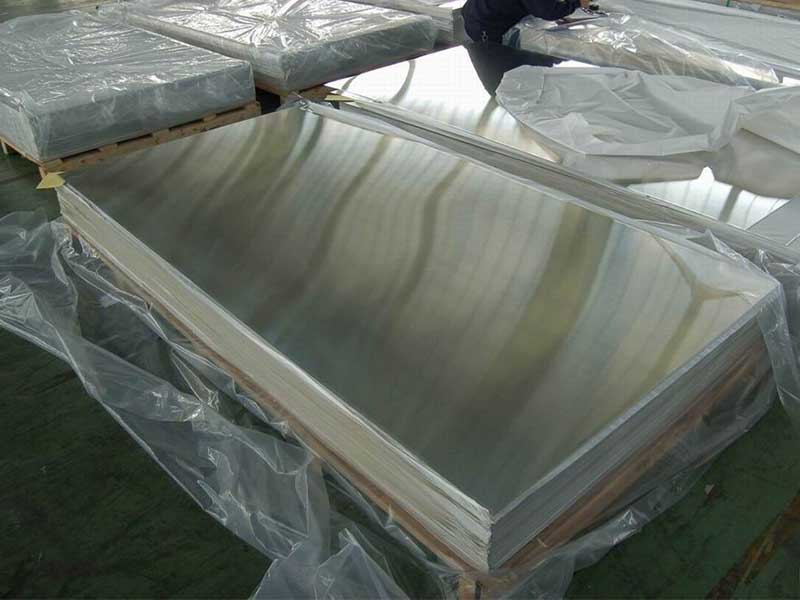

Aluminium's unique qualities—such as lightweight, corrosion resistance, formability, thermal conductivity, and strength—make it an excellent choice for PS plates. The most relevant features to consider include:

- Thickness: Ranges typically from 0.3 mm to 5.0 mm depending on specific applications.

- Aluminium Alloys: Oftentimes using alloys such as 1100, 1050, 1350, or 3003.

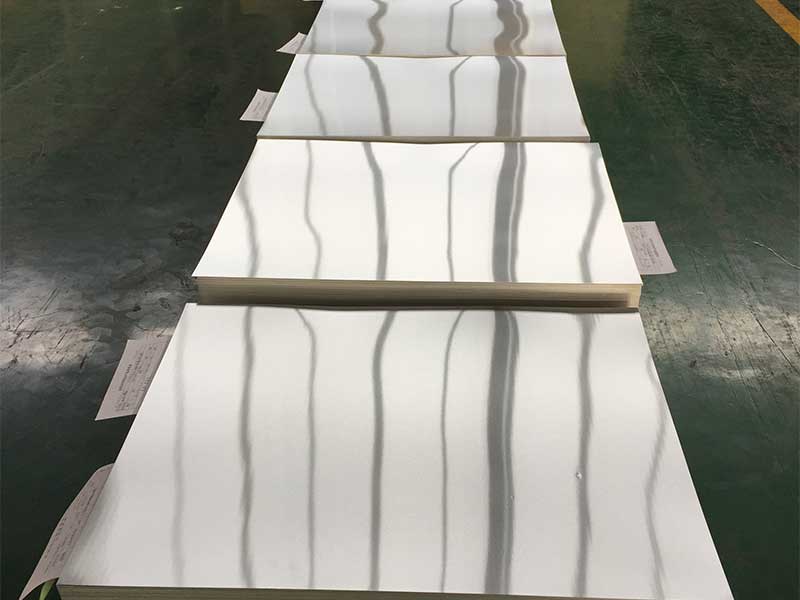

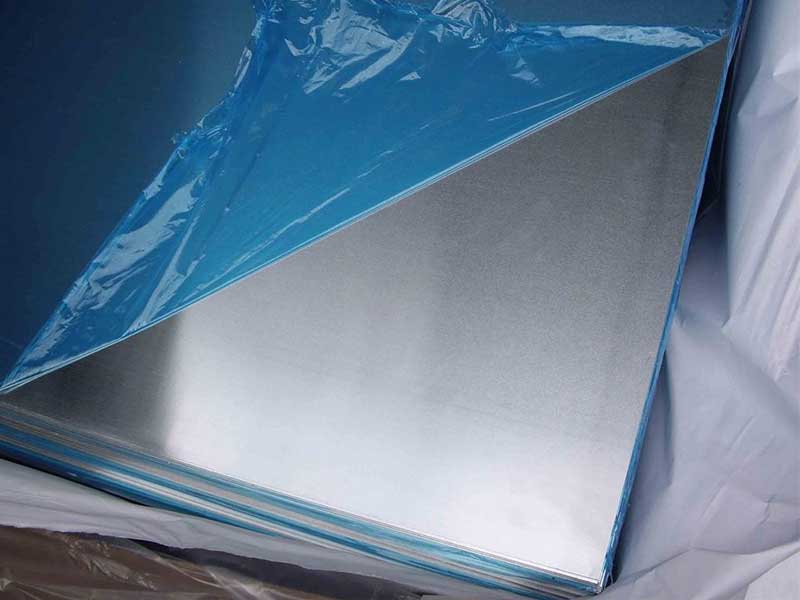

- Surface Texture: Smoothness of the surface is vital for the clarity and quality of the printed image.

- Temper: Indicates the level of tempering, typically H14 for semi-hard tempers.

Technical Specifications

| Parameter | Specifications |

|---|---|

| Thickness | 0.3 – 5.0 mm |

| Alloy Type | 1050, 1100, 1350, or 3003 |

| Temper | H14 (semi-hard) |

| Surface Finish | Anodized, Coated, or Plain |

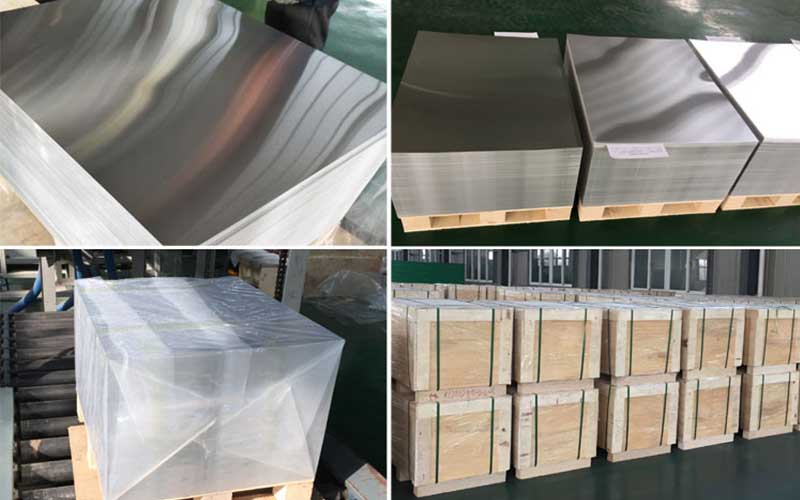

| Coil Width | Standard widths up to 1500 mm |

| Coil Weight | Up to 3 tons |

| Standard | ASTM B209 or EN AW-1050, 1100 |

Chemical Composition

The specific requirements for the chemical makeup are fundamental in determining the performance of the aluminium sheet. The most common compositions used are shown below.

| Alloy | Al (% min) | Si (% max) | Fe (% max) | Cu (% max) | Mg (% max) | Mn (% max) | Zn (% max) | Ti (% max) |

|---|---|---|---|---|---|---|---|---|

| 1050 | 99.5 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.1 |

| 1100 | 99.0 | 0.95 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.15 |

| 1350 | 99.4 | 0.3 | 0.5 | 0.02 | 0.05 | 0.2 | 0.03 | - |

| 3003 | 98.5 | 0.6 | 0.25 | 0.1 | 0.05 | 1.0 | 0.1 | - |

Performance Metrics

Performance metrics serve as the leading indicators of how well the aluminium sheet will perform in external and internal environments. attributes include:

- Electrical Conductivity: Relevant for applications where electrical portability is required.

- Corrosion Resistance: Excellent due to a natural anodized layer that helps protect against elements.

- The effect of Chemical Composition on Ductility: Varios features administering to ductility based on cobalt proportions.

Assured performance parameters for a prudently chosen aluminium sheet can include:

| Performance Metric | Values |

|---|---|

| Electrical Conductivity (% IACS) | 60 – 65 for 1050 & 1100 |

| Density (g/cm³) | 2.7 |

| Yield Strength (MPa) | 120 - 150 for temper H14 |

| Ultimate Tensile Strength (MPa) | 180 - 210 for temper H14 |

| Elongation (%) | 15% – 20% |

Applications

Aluminium sheets utilized in PS plates serve numerous functional purposes across various industries, including:

- Printing Industry: for plates used in commercial and digital printing.

- Advertising Materials: these sheets can serve as lightweight backings that support vinyl or other types of printed graphics.

- Manufacturing Components: commonly used in durable grills, finishes shielding devices essential for electrical sectors.

Benefits

The benefits of opting for aluminium sheets in PS plate applications includes:

- Light Weight: Makes handling and installation easier striving for ergonometric ports of mounting.

- High Resistance: Their sturdiness provides great longevity, essential in high-volume production environments where durability is tested.

- Easy Fabrication: The capability to be cut, shaped, riveted or adhesive-bonded offers complex developments positively affecting production speed.

- Environmentally Friendlier Option: Unlike some plastic alternatives, aluminium is 100% recyclable without loss of quality.

https://www.aluminumplate.net/a/how-to-choose-the-aluminium-sheet-for-ps-plate.html