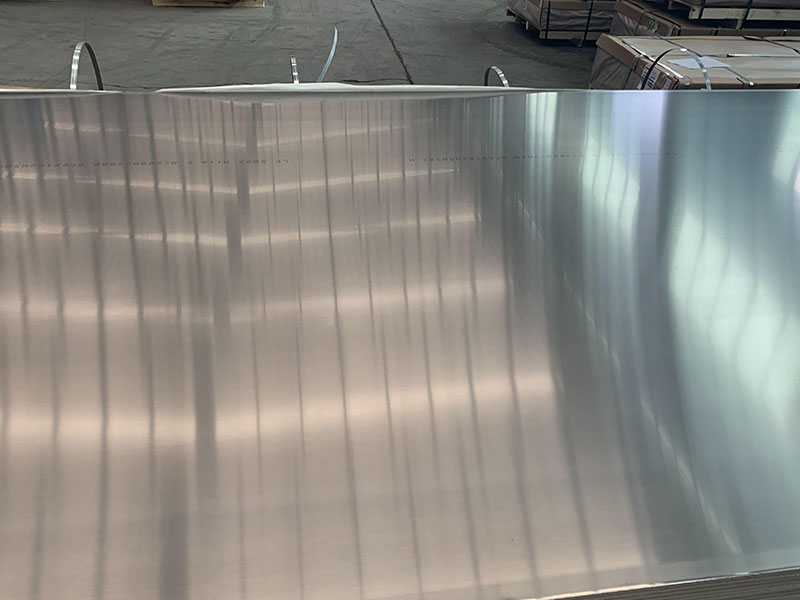

Marine grade 5083 aluminum plate

The Unsung Hero of Marine Engineering: A Fresh Look at Marine Grade 5083 Aluminum Plate

When we think about challenges faced in marine engineering, corrosion and structural integrity take center stage. Among the plethora of materials available, the marine grade 5083 aluminum plate distinctly stands out—not just as a metal sheet but as a pivotal solution born from a deep of marine environments.

What Sets 5083 Aluminum Plate Apart in Marine Applications?

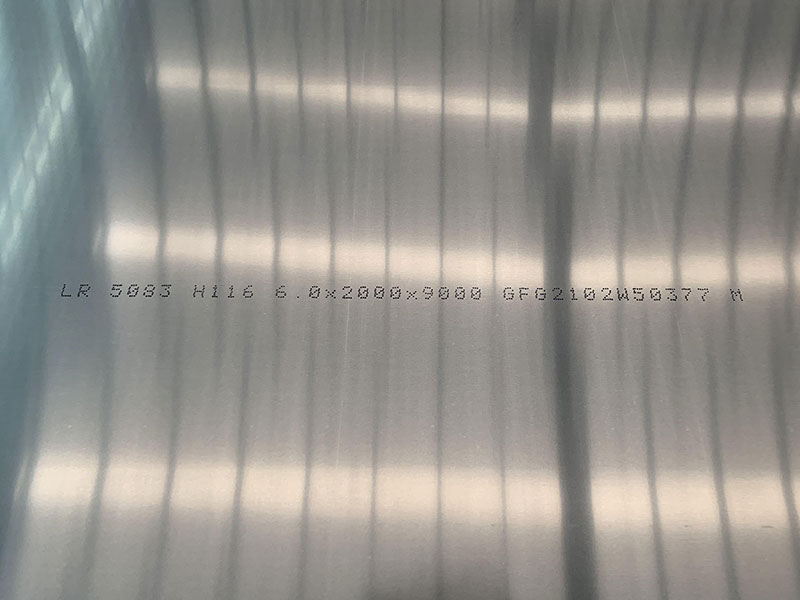

At its core, marine grade 5083 aluminum is an alloy composition optimized to withstand some of the harshest oceanic conditions. Unlike generic aluminum plates, it boasts a unique chemical makeup — primarily magnesium (4.0-4.9%) combined with traces of manganese and chromium — that imparts superior resistance to corrosion in saltwater environments. In day-to-day language, think of it as aluminum that's been engineered with a natural armor against the relentless assault of sea water and maritime chemicals.

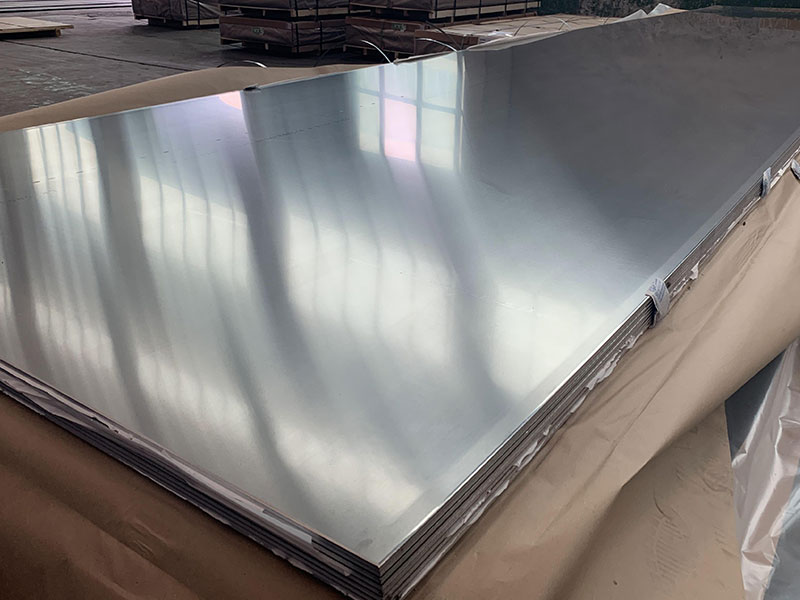

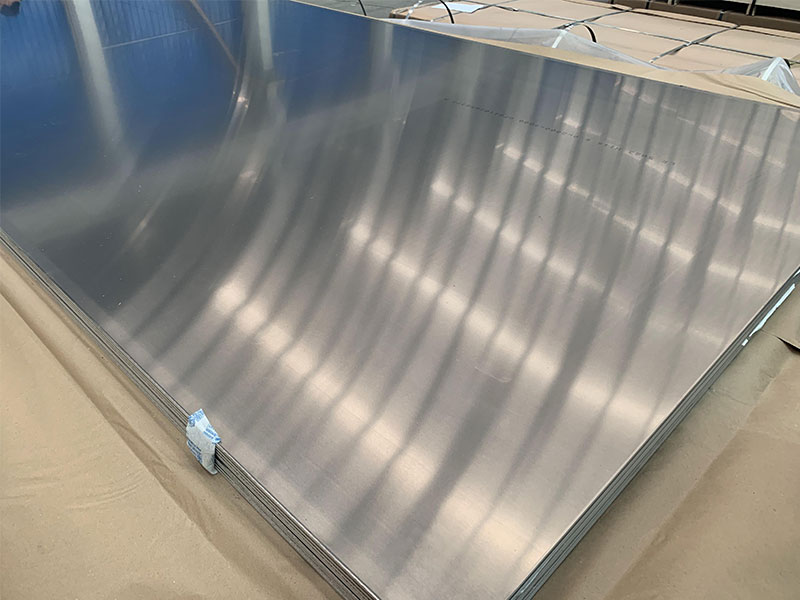

But it’s not just about resisting corrosion. The 5083 aluminum plate is known for its extraordinary strength-to-weight ratio. Lightweight yet robust, it makes the ideal structural choice for marine vessels, including hulls, decks, and superstructures. Meaning? Builders can design vessels that are faster, more fuel-efficient, and longer-lasting – all while keeping crew safety at the forefront.

Technical Insights: The Role of Magnesium and Manufacturing Processes

The secret sauce lies in magnesium flushing through the alloy, strengthening it via solid solution strengthening. This combination grants the 5083 aluminum grade its excellent mechanical attributes—yield strength ~193 MPa (near matching mild steels) without the weight penalty of steel. Moreover, its fatigue resistance ensures it weathers repetitive stresses caused by ocean waves over long periods.

Manufacturing technologies employed to produce the 5083 marine aluminum plate — such as rolling and heat treatment during the T3 tempering process — finely control the microstructure. This results in a plate that harmonizes malleability with toughness, simplifying fabrication processes like welding and forming into complex ship components.

Why Not Steel or Other Alloys?

While steel might seem a traditional go-to in shipbuilding, 5083 aluminum effortlessly overcomes steel’s drawbacks when operating in marine atmospheres. Steel requires heavy anti-corrosive paints and frequent maintenance against rust, adding to operational costs and weight. By contrast, 5083 aluminum minimises upkeep and enables innovative design scalability.

Furthermore, compared to other aluminum alloys — 5083 uniquely balances corrosion resistance and strength, outperforming options like 6061 or 5052 in seawater endurance. This helps naval architects invest with confidence in durable structures without over-specifying weight or material thickness.

Real-Life Impact: Sustainability and Operational Efficiency

Adopting marine grade 5083 aluminum plate also advances sustainability agendas within marine industries. Its corrosion resistance leads to extended vessel lifespans and less material wastage over cycles of remodeling. In lighter ship builds, fuel consumption drops, subsequently lowering carbon emissions linked with marine transport.

The story of marine grade 5083 aluminum plate paints the narrative of a deceptively simple metal—transforming ocean challenges into lasting opportunity. As demands for safer, smarter, and environmentally conscious watercraft increase, embracing 5083 aluminum is truly sailing towards the perfect material choice.

https://www.aluminumplate.net/a/marine-grade-5083-aluminum-plate.html