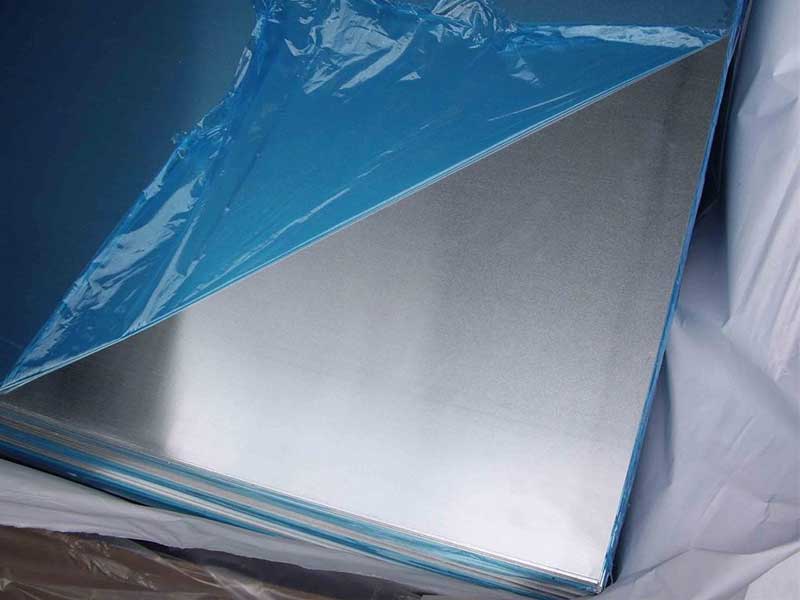

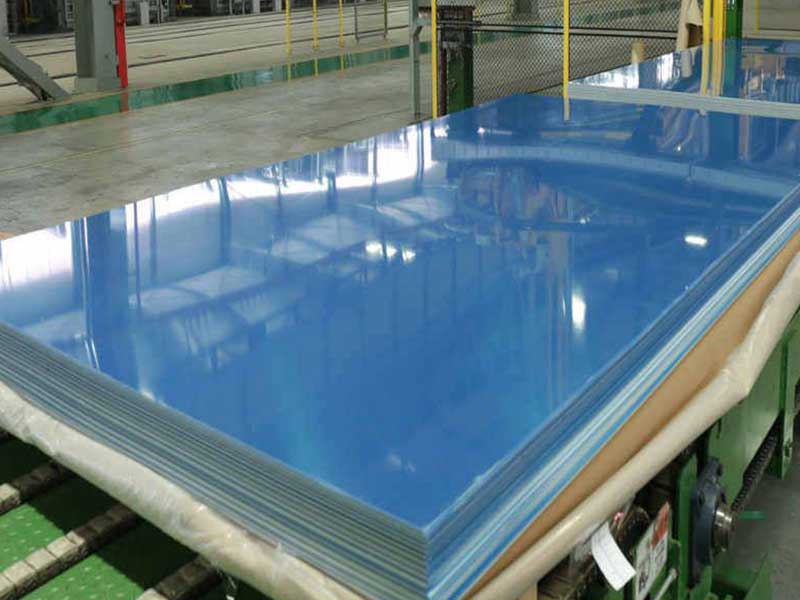

Mill Fish Alloy Anodized Aluminum Plate

Mill Fish Alloy Anodized Aluminum Plate is a high-performance aluminum product engineered for both aesthetic appeal and industrial durability. This particular alloy, treated with a fine anodizing process, inherits superior corrosion resistance, enhanced surface hardness, and distinct visual characteristics that make it a preferred choice in a variety of industries. Combining the mechanical properties of Mill Fish aluminum alloys with the advanced protective capabilities of anodizing, this product delivers longevity and functional advantages for demanding applications.

Alloy Composition and Detailed Properties

The "Mill Fish" alloy typically refers to a specialized aluminum formulation renowned for its optimal strength-to-weight ratio and machining efficiency. While the exact chemical formulation may vary depending on manufacturer specifications, the alloy aligns closely with popular marine- and machinery-grade standards like 5005 or 6061 series aluminum, optimized for anodizing compatibility.

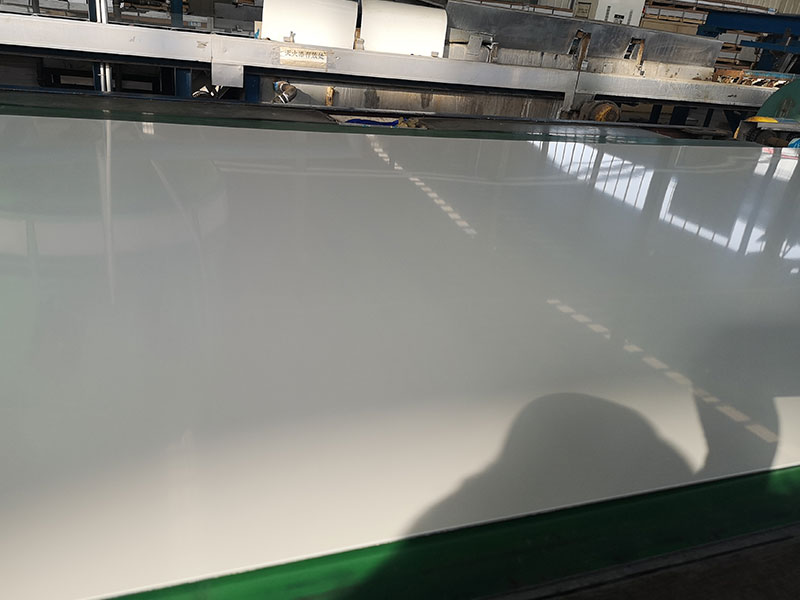

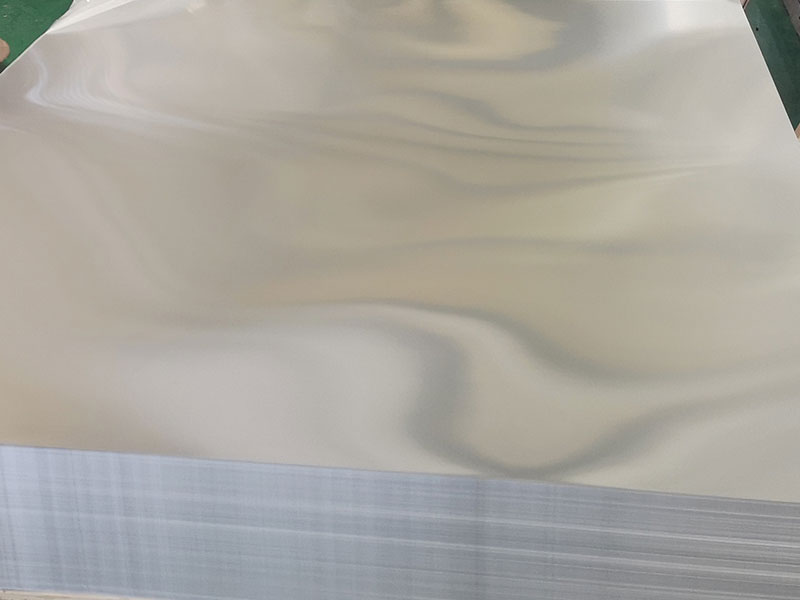

Mill finish alloy anodized aluminum plate presents a unique set of challenges and opportunities compared to other anodized aluminum finishes. The "mill finish" itself, lacking any pre-treatment beyond the initial milling process, means the inherent surface irregularities of the aluminum alloy are fully exposed before anodizing. This can lead to inconsistent dye penetration and a slightly less uniform final color compared to a chemically etched or polished substrate. Furthermore, the varying grain structure inherent in different aluminum alloys impacts the final anodized surface's hardness and wear resistance, demanding careful selection of the alloy and anodizing process parameters for optimal performance. We've found that certain alloys, particularly those with higher silicon content, can be more prone to pitting during anodizing, necessitating stricter quality control measures.

Addressing these challenges often involves pre-anodizing surface treatments tailored to the specific alloy. We might implement a light chemical etching to improve surface uniformity and promote better dye adhesion before the anodizing process. This extra step, while adding to production cost, significantly enhances the final aesthetic quality and durability of the product, particularly crucial for applications requiring a consistently smooth and colorfast finish. Analyzing the final product with advanced surface profilometry allows us to fine-tune our pre-treatment procedures, ensuring a consistent, high-quality mill finish anodized aluminum plate for our clients, regardless of the chosen alloy.

| Alloy Parameter | Typical Content (%) | Purpose |

|---|---|---|

| Aluminum (Al) | Balance | Base metal providing lightweight and corrosion resistance |

| Magnesium (Mg) | 0.7 – 1.2 | Improves strength and anodizing response |

| Silicon (Si) | 0.0 – 0.4 | Enhances castability and surface finish |

| Iron (Fe) | 0.0 – 0.7 | Minor additions from raw material, can affect grain structure |

| Copper (Cu) | ≤ 0.1 | Minimizes corrosion susceptibility |

| Manganese (Mn) | 0.1 – 0.5 | Improves toughness and corrosion resistance |

| Chromium (Cr) | 0.05 – 0.2 | Promotes hardenability and corrosion resistance |

Anodizing is an electrochemical surface treatment that thickens the natural oxide layer on aluminum, significantly enhancing wear resistance, hardness, and corrosion protection. The Mill Fish Alloy Anodized Aluminum Plate undergoes:

- Pre-Cleaning and De-Greasing: Removal of surface contaminants to ensure uniform anodic layers.

- Electrolytic Anodizing: A controlled sulfuric acid bath creates a thickened and porous aluminum oxide film.

- Sealing: The porous anodic oxide layer is sealed to lock in corrosion protection and dye (optional).

Common anodized coatings on Mill Fish Alloy plates measure between 12–25 microns in thickness, providing excellent mechanical durability.

Features

- Enhanced Corrosion Resistance: Anodizing protects the metal from chemical attack and marine atmosphere degradation.

- Improved Surface Hardness: Surface hardness can reach 15–20 times that of untreated aluminum, increasing wear resistance.

- Aesthetic Flexibility: Anodized surface offers a bright, matte finish that can be dyed in variety of colors for design flexibility.

- Lightweight and Strong: Great strength-to-weight appropriate for transportation and structural applications.

- Excellent Fabrication Characteristics: Can undergo bending, cutting, welding, and machining with minimal surface blemishes or warping.

- Anti-Slip Surface Texture: Slight anodized roughness is beneficial in floor and walkway plating, providing enhanced safety.

- Environmentally Friendly: Non-toxic surface coating and recyclable materials make it a sustainable choice.

Mechanical Properties

| Property | Typical Value (Mill Fish Anodized Aluminum) | Units |

|---|---|---|

| Density | 2.70 | g/cm³ |

| Tensile Strength | 200 – 280 | MPa |

| Yield Strength | 120 – 220 | MPa |

| Elongation at Break | 8 – 15 | % |

| Hardness (Surface) | 400 – 600 HV (Vickers, anodized layer) | HV |

| Thermal Conductivity | 130 – 160 | W/m·K |

| Electrical Conductivity | 30 – 40 | % IACS |

Typical Applications

1. Architectural and Interior Design

Mil fish alloy anodized plates are extensively used in modern architecture for decorative panels, façades, elevator interiors, and wall cladding owing to their lasting sheen, resistance to weathering, and option for enriched colors.

2. Marine and Offshore Equipment

With its great corrosion resistance against saltwater, anodized aluminum plates serve well in shipbuilding, boat flooring, decks, and offshore platform components where both mechanical integrity and anti-corrosion coatings are critical.

3. Electrical & Electronic Components

Anodized aluminum’s stable oxide film acts as an electrical insulator and protective layer, perfect for enclosures, heat sinks, and shell casings in electronics.

4. Transportation and Automotive

The combination of low weight and anodized protection offers durability and aesthetic enhancements in bus flooring, rail vehicle components, truck side panels, and related structural elements.

5. Industrial Machinery

Its high hardness and anti-corrosion characteristics make it suitable for manufacturing machine guards, wearable parts, and caching plates.

6. Consumer Goods & Appliances

Anodized aluminum plates appear in PC chassis, consumer product housings, kitchen appliances, and furniture, ensuring both appeal and longevity.

Handling and Maintenance

To maximize the service life of the Mill Fish Alloy Anodized Aluminum Plate:

- Clean routinely using mild detergent and water to remove pollutants.

- Avoid prolonged exposure to strongly acidic or alkaline substances.

- Physical abrasion should be minimized to protect the uninterrupted anodized surface.

- Store sheets in dry, clean environments to prevent premature aging.

The Mill Fish Alloy Anodized Aluminum Plate offers a unique blend of mechanical strength, excellent corrosion resistance, surface hardness, and attractive finishing. Its versatility across architectural, marine, electronics, and transportation sectors testifies to its engineered quality. By electing this anodized plate, customers gain access to a sustainable, durable, and aesthetically customizable aluminum solution engineered for the long term.

For orders, specifications, or samples of Mill Fish Alloy Anodized Aluminum Plates, please contact our technical sales team or visit our website.

Note: Information about specific alloy compositions, anodizing thickness, and mechanical properties may vary depending on producer standards or customer customization. Customers should consult product datasheets before design integration.

https://www.aluminumplate.net/a/mill-fish-alloy-anodized-aluminum-plate.html