Anodized aluminum sheet 5005 5052 5083

Anodized aluminum sheets are widely used across various industries due to their enhanced corrosion resistance, aesthetically appealing surface finish, and improved durability. Sheet alloys such as 5005, 5052, and 5083 are three commonly used grades for anodizing, each with unique chemical compositions and mechanical properties catering to specific industrial requirements.

What is Anodized Aluminum Sheet?

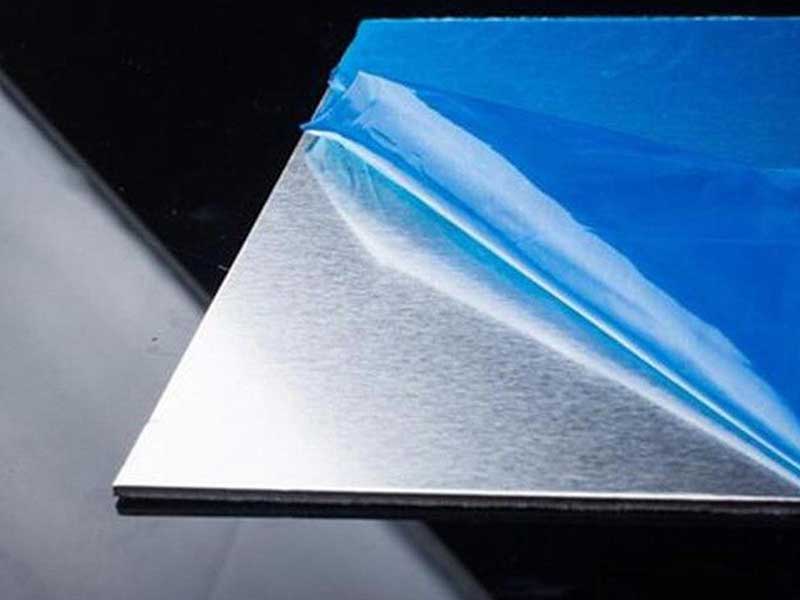

Anodizing is an electrochemical process that converts the aluminum surface into a durable, corrosion-resistant, anodic oxide finish. This oxide surface is non-conductive, hard, and can be color-treated or left transparent, making it ideal for applications requiring both mechanical strength and superior visual aesthetics.

Working with 5005, 5052, and 5083 anodized aluminum sheets daily, I've come to appreciate their subtle differences beyond the specs. 5005, with its higher manganese content, feels noticeably stiffer during handling, making it a better choice for applications demanding structural integrity. The anodizing process itself – whether it's a clear coat or a colored finish – dramatically alters the feel; the clear anodize gives a slightly smoother, almost glassy surface compared to the slightly more textured feel you get with colored anodizing. I've noticed that the 5052, while slightly less strong, often boasts a superior surface finish after anodizing, making it preferable for applications requiring a consistently flawless aesthetic. This often translates to higher demand from our clientele making specific aesthetic requirements.

Beyond the material properties, I've observed interesting quirks during production. For example, achieving a uniform anodize on sheets of differing thicknesses within the same batch can be tricky, requiring careful adjustment of the anodizing parameters. Similarly, the different alloys react slightly differently to the dye penetration during colored anodizing; 5083, with its higher magnesium content, sometimes requires a slight tweak in the dyeing process to achieve the desired color saturation. These nuances are often overlooked in technical manuals but become second nature through hands-on experience, allowing us to fine-tune our processes and minimize

Alloy Composition & Chemical Properties

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Others (%) | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|

| 5005 | 0.3 max | 0.7 max | 0.1 max | 0.2-0.7 | 0.5-1.1 | 0.2 max | 0.1 max | 0.1 max Al+Cr | Bal |

| 5052 | 0.25 max | 0.4 max | 0.1 max | 0.1 max | 2.2-2.8 | 0.1 max | 0.15 max | 0.1 max | Bal |

| 5083 | 0.4 max | 0.4 max | 0.1 max | 0.4-1.0 | 4.0-4.9 | 0.25 max | 0.15 max | 0.05 max | Bal |

Mechanical Properties (Typical for Annealed Condition (O Temp))

| Property | 5005-O | 5052-O | 5083-H116 |

|---|---|---|---|

| Tensile Strength (MPa) | 140-190 | 210-275 | 290-340 |

| Yield Strength (MPa) | 65-110 | 150-220 | 230-270 |

| Elongation (%) | 8-12 | 10-16 | 12-18 |

| Hardness (HB) | 40-50 | 50-70 | 70-90 |

Temper Designations and their Impact

- O (Annealed): Softest temper with maximum ductility and corrosion resistance. Ideal for bending and forming before anodizing.

- H1X (Strain Hardened): Increases hardness and strength through mechanical work like rolling.

- H116 (Improved Corrosion Properties): Used specifically for alloys like 5083, enhancing corrosion resistance without overstressing material.

- H34/H36: Often used for specific mechanical strength requirements in industry.

Temper must be chosen carefully because the anodizing process is sensitive, and over-hardened aluminum will behave differently under anodization.

Anodizing Process Standards Related to 5005, 5052, and 5083 Grades

- MIL-A-8625F Type II / Type III: The US Military specification defining sulfuric acid anodizing, ensuring corrosion-resistant coatings.

- BS EN ISO 7599: Electrochemical anodizing of aluminum and aluminum alloys.

- AAMA 611: Voluntary specification for Anodized Architectural Aluminum.

These standards dictate thickness, adhesion, hardness, and corrosion resistances ensuring that anodized sheets meet application reliability levels.

Advantages of Anodized Aluminum Sheets

| Advantage | Explanation |

|---|---|

| Corrosion Resistance | Thick oxide layer protects aluminum substrate in harsh environments |

| Enhanced Aesthetic Appeal | Variety of natural or dyed colors enhance visual property without paint or coating |

| Increased Surface Durability | Hard anodized layers resist wear, scratching, and weather effects |

| Environmentally Friendly | 100% recyclable material with zero emissions during anodizing process |

| Electrical Insulation | Anodized layer provides superior insulation, useful in electronics applications |

Applications of Anodized 5005, 5052, and 5083 Sheets

| Alloy | Typical Use Case |

|---|---|

| 5005 | Decorative panels, ceilings, roadside signage, solar reflectors where aesthetics are crucial |

| 5052 | Marine equipment, chemical tanks, boats due to good corrosion resistance and formability |

| 5083 | Heavy-duty structural components in marine vessels, aerospace & defense, cryogenic containers |

| Alloy | Core Benefit | Suitability for Anodizing |

|---|---|---|

| 5005 | High finish quality and corrosion resistance | Excellent |

| 5052 | Superior corrosion resistance and moderate strength | Good |

| 5083 | High strength alloy for severe environments | Good but requires careful process control |

https://www.aluminumplate.net/a/anodized-aluminum-sheet-5005-5052-5083.html