Mirror Anodizing 3004 H14 Aluminum Sheet

Mirror anodizing transforms a functional aluminum sheet into a precision surface—bright, reflective, corrosion‑resistant, and easy to clean. When this process is applied to 3004 H14 aluminum sheet, the result is a material that balances visual impact with structural reliability. This combination is especially attractive for customers who need both appearance and performance in one product.

Below is a practical, customer‑oriented look at mirror anodized 3004 H14 aluminum: how it is made, what makes it different, and which technical parameters you should actually pay attention to when choosing it.

What makes 3004 H14 special for mirror anodizing?

The 3004 alloy belongs to the 3xxx series aluminum–manganese family. It is non‑heat‑treatable and strengthened mainly by work hardening. For mirror anodizing, the alloy’s chemistry and temper work together in important ways:

- The manganese content gives 3004 better strength than pure aluminum, while keeping good ductility. This is useful if your reflective panels need light forming, bending or shallow drawing.

- The magnesium addition (compared with 3003) improves strength and slightly boosts work‑hardening response.

- The low copper content helps improve corrosion resistance and gives a more stable anodized surface.

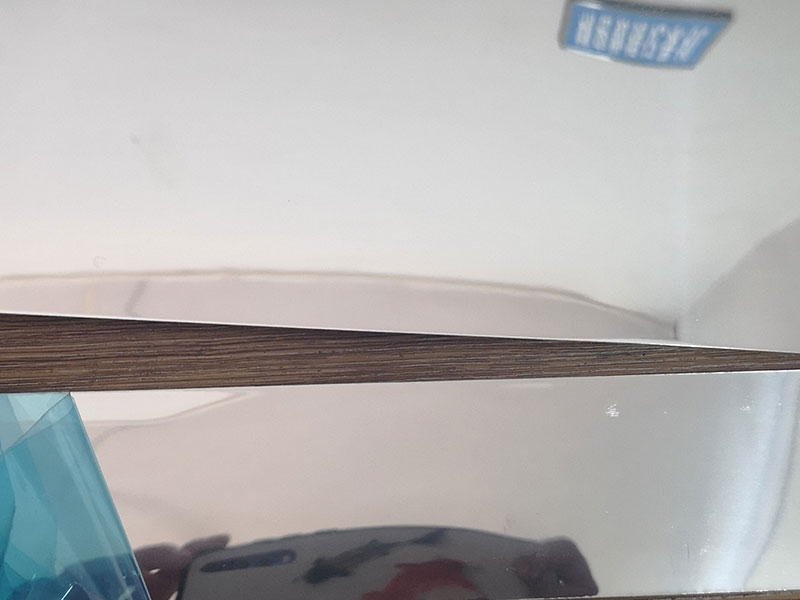

The H14 temper means “half‑hard,” obtained through cold working. In practical terms, H14 offers a sweet spot: stiff enough to handle and install without denting too easily, but still formable for common fabrication processes such as bending, punching, or light embossing.

For mirror anodizing, this balance is crucial. A sheet that is too soft deforms during polishing and handling; a sheet that is too hard can crack during forming or show stress marks in the reflective surface.

What exactly is mirror anodizing?

Mirror anodizing is not a single step, but a controlled sequence of surface preparation, mechanical or chemical polishing, and anodic oxidation. The goal is to turn the aluminum sheet into a clear, bright, specular surface while building a protective anodic film.

From a materials viewpoint, there are three stages:

Surface leveling and polishing

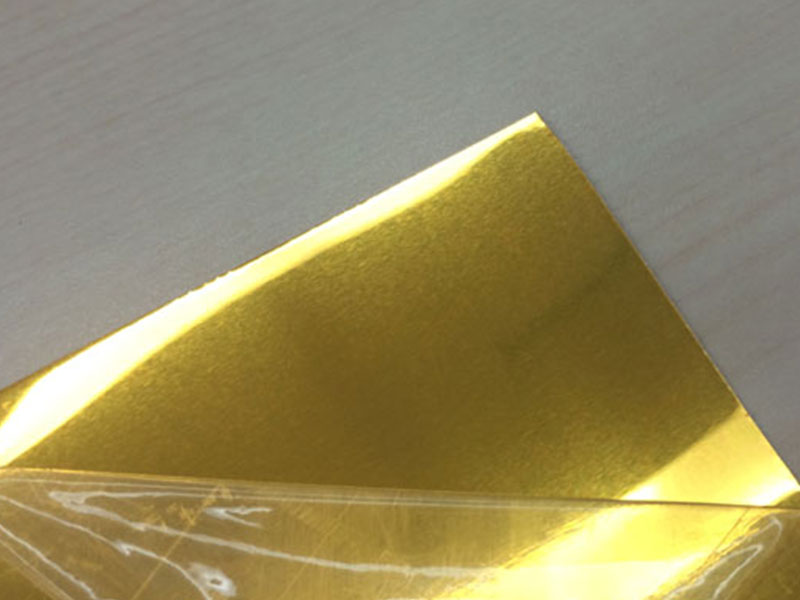

The 3004 H14 sheet is first rolled and finished to a very smooth base. It may be mechanically polished, chemically brightened, or electro‑polished. This step determines how “mirror‑like” the sheet will look. Anodizing alone does not create gloss; it preserves and enhances the finish underneath.Anodic oxidation

The sheet is immersed in an acidic electrolyte (commonly sulfuric acid) and connected as the anode in an electric circuit. A controlled oxide layer grows from the aluminum surface. For mirror applications, this layer is usually thin to medium thickness, keeping high transparency and brightness.Sealing

After anodizing, the pores of the oxide layer are sealed, commonly in hot deionized water or with nickel‑based sealing solutions. This step locks in the appearance and improves corrosion and stain resistance.

When all three are tuned for 3004 H14, you get a bright, even reflection, with consistent color tone and good resistance to fingerprints, weathering and mild chemicals.

Why choose 3004 H14 over other mirror aluminum?

The market offers mirror finishes on several alloys; 1050, 1100 and 3003 are typical. 3004 H14 stands out in a few situations:

- Higher strength for the same thickness, reducing the risk of “oil canning” or waviness in large panels.

- Better formability than harder alloys used in some decorative systems, especially where light structural performance is needed.

- More stable anodized color tone compared with alloys containing higher copper or silicon.

In architectural ceilings, interior wall cladding, lighting reflectors or decorative appliance panels, this alloy‑temper combination often performs better when panels are large, or when moderate forming is required without sacrificing the mirror surface.

Typical product parameters for mirror anodized 3004 H14 sheet

Exact values depend on manufacturer and specification, but the following ranges are common in commercial mirror anodized 3004 H14 products:

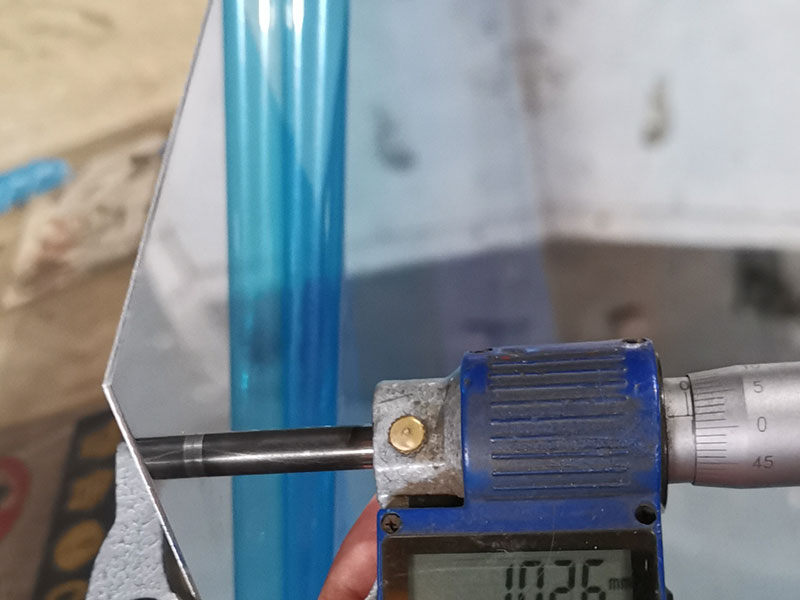

- Thickness range: often from 0.25 mm to about 3.0 mm

- Common widths: 1000 mm, 1200 mm, 1250 mm, 1500 mm (custom widths available by coil)

- Length: cut‑to‑length sheets or continuous coils

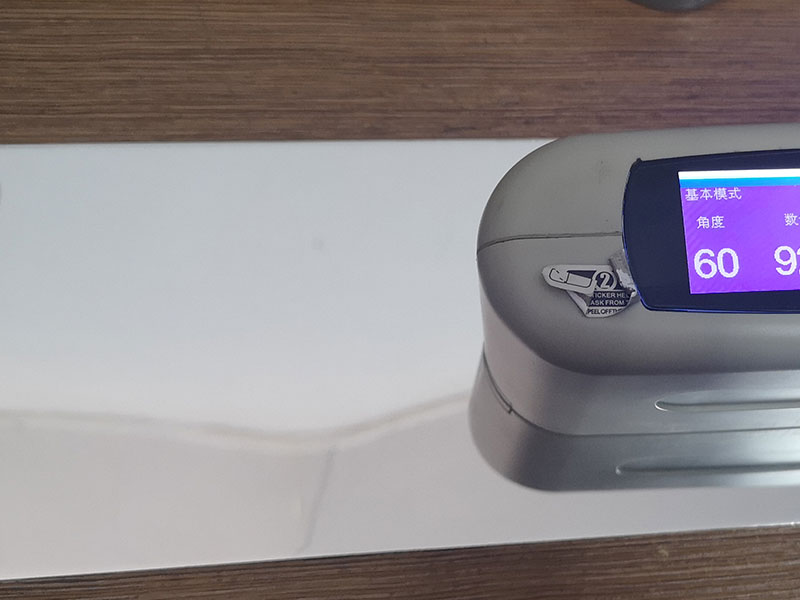

- Surface brightness: specular reflectance often in the range of 80–90% depending on finish grade

- Anodized layer thickness: usually 5–15 μm for indoor decorative use; 10–25 μm for exterior or higher‑demand environments

- Surface finishes: mirror bright, high gloss, or directional reflective finishes; some suppliers offer colored anodized mirror surfaces (silver, champagne, bronze, black)

If you specify a project, it is useful to define not only thickness and size, but also anodic layer thickness and reflectivity level, especially when matching existing installations or lighting requirements.

Implementation standards and quality references

Mirror anodized 3004 H14 aluminum sheets are generally produced under a combination of alloy, mechanical property, and anodizing standards. Depending on region and application, typical references include:

Alloy and temper

- ASTM B209 for aluminum and aluminum‑alloy sheet and plate

- EN 573‑3 for chemical composition of wrought aluminum alloys

- EN 485 series for mechanical properties and tolerances

Anodizing quality

- ISO 7599 for anodizing of aluminum and its alloys – general specifications for anodic oxidation coatings

- ISO 2360 or ISO 2376 for measuring anodic coating thickness

- EN 12373 series (where applicable) for anodic oxidation requirements

In many projects, customers define their own internal appearance standards, including gloss level, color tolerance (for example, ΔE in CIELAB color space), and inspection angles for mirror quality.

Values may vary slightly by producer and thickness; the ranges below are typical reference levels for specification comparison:

- Tensile strength (Rm): approximately 190–240 MPa

- Yield strength (Rp0.2): approximately 120–160 MPa

- Elongation (A50): typically 8–15% for standard thickness range

- Modulus of elasticity: about 70 GPa

- Density: about 2.73 g/cm³

This set of properties explains why 3004 H14 is often chosen for lightweight construction, ceiling and facade systems, and reflective panels that need both stiffness and manageable weight.

Chemical composition table for 3004 alloy

Typical composition limits for 3004 aluminum (mass percentage, wt.%):

| Element | Typical Range (wt.%) |

|---|---|

| Si | ≤ 0.30 |

| Fe | ≤ 0.70 |

| Cu | ≤ 0.25 |

| Mn | 1.0 – 1.5 |

| Mg | 0.8 – 1.3 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Other, each | ≤ 0.05 |

| Other, total | ≤ 0.15 |

| Al | Balance |

This chemistry supports good anodizing behavior. Low copper and controlled iron help avoid discoloration or uneven oxide films. Manganese and magnesium deliver the desired strength without severely compromising corrosion resistance.

Where mirror anodized 3004 H14 works best

The value of this material emerges most clearly in real applications, where both appearance and performance matter:

- Interior and semi‑exterior architectural elements: ceiling panels, column covers, decorative wall panels, elevator surrounds, display backdrops.

- Lighting and optical uses: reflector bodies, light guides, retail lighting systems, signage backplates.

- Appliance and furniture fields: front panels, trim, control panels, door frames that require scratch‑resistant, high‑gloss metal surfaces.

- Transportation interiors: decorative trims, panels and covers where weight reduction and brightness are important.

In these uses, the mirror anodic layer not only reflects light and creates a high‑end visual effect, but also protects the underlying 3004 alloy from fingerprints, mild abrasion, moisture and daily contamination.

Practical selection tips

When specifying mirror anodized 3004 H14 aluminum sheet, a few practical considerations make a big difference:

- Define the application environment: indoor, outdoor, or high‑humidity areas, then choose an appropriate anodic film thickness.

- Consider forming requirements before choosing thickness and hardness; H14 is versatile, but heavy forming may require process trials.

- Ask for sample panels under your lighting conditions; mirror appearance changes with viewing angle and light source.

- Ensure that all batches for a single project come from consistent production parameters to avoid visible tone or gloss differences.

Mirror anodized 3004 H14 aluminum sheet brings together the visual clarity of a mirror finish with the structural reliability of a mid‑strength alloy. For customers seeking a reflective surface that is more than just decorative, it offers a durable, corrosion‑resistant and formable solution that fits modern architectural, lighting and industrial design needs.

https://www.aluminumplate.net/a/mirror-anodizing-3004-h14-aluminum-sheet.html