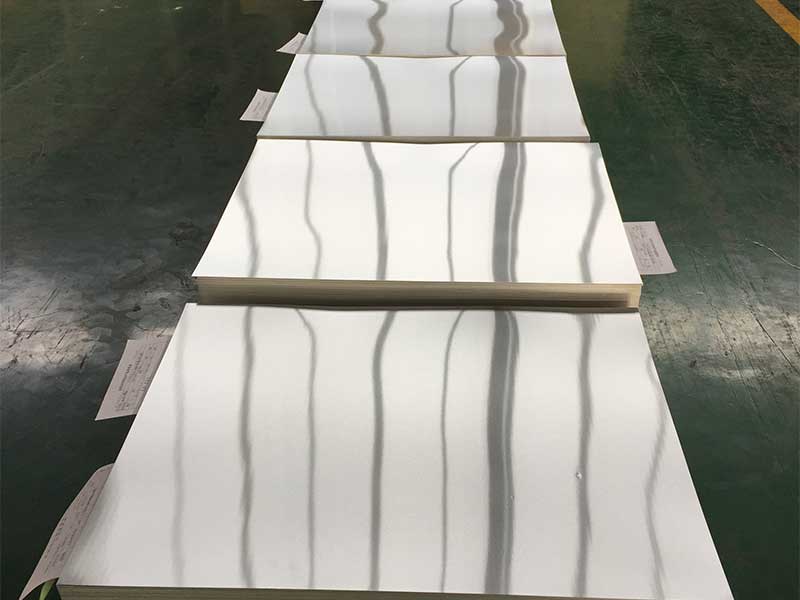

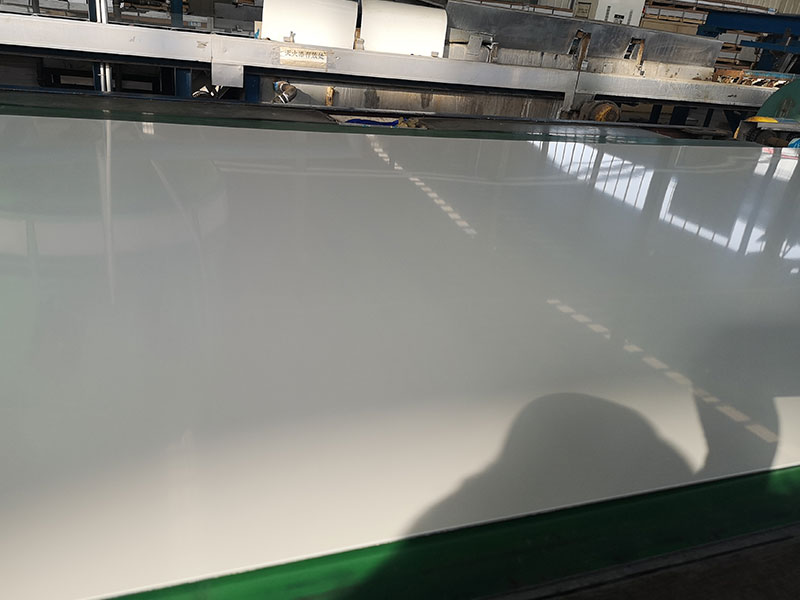

T4 T6 T651 6061 aluminum sheet plate

T4 T6 T651 6061 aluminum sheet plate is a high-strength, heat-treatable alloy widely used in aerospace, transportation, mold making, and structural components. It offers an excellent balance of strength, weldability, machinability, and corrosion resistance. Available in T4, T6, and T651 tempers, 6061 plate can be tailored for bending, precision machining, or high-load structural use.

6061 aluminum is a precipitation-hardened alloy based on the Al–Mg–Si system. It is one of the most widely used structural alloys due to its:

- High specific strength

- Good corrosion resistance

- Excellent machinability in heat-treated tempers

- Reliable weldability and formability

The tempers T4, T6, and T651 represent different stages of solution heat treatment and artificial aging, allowing you to choose between better formability (T4) and maximum mechanical strength and stability (T6, T651).

Chemical Composition of 6061 Aluminum

Typical composition according to common international standards (mass fraction):

| Element | Typical Range (%) |

|---|---|

| Silicon (Si) | 0.40 – 0.80 |

| Magnesium (Mg) | 0.80 – 1.20 |

| Copper (Cu) | 0.15 – 0.40 |

| Chromium (Cr) | 0.04 – 0.35 |

| Iron (Fe) | ≤ 0.70 |

| Manganese (Mn) | ≤ 0.15 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminum (Al) | Balance |

This Al–Mg–Si–Cu composition delivers a strong precipitation-hardening response while maintaining good corrosion resistance and weldability.

Temper Designations: T4 vs T6 vs T651

Temper Description

| Temper | Treatment Route | Main Characteristics | Typical Use Focus |

|---|---|---|---|

| T4 | Solution heat treated, naturally aged | Medium strength, excellent formability and bendability | Complex forming, deep bending |

| T6 | Solution heat treated, artificially aged | High strength, good machinability, fair formability | Structural parts, machined components |

| T651 | Solution heat treated, stress-relieved by stretching, artificially aged | High strength with reduced residual stress, excellent dimensional stability | Precision machining, molds, tooling |

T651 is essentially T6 that has been mechanically stress-relieved, making it the preferred choice for thick plates and tight-tolerance machined parts where distortion must be minimized.

Features and Performance Advantages

Mechanical and Processing Features

| Feature | Description |

|---|---|

| Strength-to-weight ratio | Significantly higher than many non-heat-treatable alloys |

| Machinability | Very good in T6/T651; produces clean chips and stable cutting |

| Weldability | Readily weldable by TIG/MIG; good post-weld strength with proper procedure |

| Formability | Best in T4; moderate in T6 for larger radii bends |

| Dimensional stability | T651 minimizes warping during heavy machining |

| Surface finish | Suitable for anodizing, powder coating, and mechanical polishing |

| Corrosion resistance | Good in most atmospheric and industrial environments |

Comparison of Tempers for Common Needs

| Requirement | Recommended Temper | Reason |

|---|---|---|

| Tight-tolerance machining | T651 | Stress relief reduces distortion and residual stresses |

| Deep bending or complex forming | T4 | Higher ductility and elongation |

| High static load structural use | T6 or T651 | Maximum yield and tensile strength |

| General welded structures | T6 (locally softened at weld) | Good overall balance after welding |

Mechanical Properties (Typical Values)

Typical room temperature properties for 6061 plate (approximate, for reference only; check actual MTC for guaranteed values):

| Property | Unit | 6061‑T4 | 6061‑T6 | 6061‑T651 |

|---|---|---|---|---|

| Tensile strength (Rm) | MPa | 180 – 240 | 260 – 310 | 260 – 310 |

| Yield strength (Rp0.2) | MPa | 110 – 160 | 240 – 280 | 240 – 280 |

| Elongation (A50) | % | 12 – 20 | 8 – 12 | 8 – 12 |

| Brinell hardness | HBW | 60 – 75 | 85 – 100 | 85 – 100 |

| Modulus of elasticity | GPa | ~69 | ~69 | ~69 |

| Density | g/cm³ | 2.70 | 2.70 | 2.70 |

| Thermal conductivity | W/m·K | ~170 | ~170 | ~170 |

| Coefficient of thermal expansion | µm/m·K | 23 – 24 | 23 – 24 | 23 – 24 |

Standard Sizes, Thickness Range, and Tolerances

Actual availability may vary; the table below gives common commercial ranges:

| Parameter | Typical Range / Note |

|---|---|

| Thickness (sheet) | 0.5 – 6.0 mm |

| Thickness (medium plate) | 6 – 25 mm |

| Thickness (heavy plate) | 25 – 200+ mm (mainly T6/T651) |

| Standard widths | 1000 mm, 1220 mm, 1500 mm, up to 2000 mm |

| Standard lengths | 2000 mm, 2440 mm, 3000 mm, 4000 mm or cut-to-length |

| Thickness tolerance | Typically ±0.1 – ±0.5 mm, depending on gauge and standard |

| Flatness (plate) | Controlled especially in T651 for machining applications |

For CNC machining, T651 plates are often ordered in customized cut-to-size blocks to reduce waste and machining time.

Applications of T4 T6 T651 6061 Aluminum Sheet Plate

Structural and Mechanical Components

| Industry / Area | Typical 6061 Plate Uses |

|---|---|

| Aerospace & aviation | Fixtures, brackets, tooling plates, non-critical structural parts |

| Transportation | Truck bodies, trailers, bus floors, ship deck plates |

| Machinery & equipment | Machine bases, frames, jigs, robot arms, precision fixtures |

| Construction | Roof panels, curtain wall frames, handrails, walkways |

High-Precision and Mold Uses

| Segment | Application Details |

|---|---|

| Mold making | Plastic molds, blow molds, casting patterns (commonly T651) |

| CNC machining | Tooling plates, base plates, electronic equipment housings |

| Automation | Linear guide bases, positioning plates, component carriers |

General Fabrication & Consumer Products

| Segment | Typical Products |

|---|---|

| Sporting & leisure | Bicycle frames (parts), camera rigs, accessories |

| Marine & outdoor | Small boat components, gangways, platforms |

| Electronics & hardware | Enclosures, heat-dissipating structural parts |

T4 is preferred for parts that need complex bending first and are then aged to near‑T6 strength, while T6/T651 are chosen for finished plates that will go straight into cutting and machining.

Forming, Welding, and Machining

Forming and Bending

| Temper | Bending Performance | Notes |

|---|---|---|

| T4 | Excellent | Recommended for tight radii and deep forming |

| T6 | Moderate | Use larger bend radii, avoid sharp corners |

| T651 | Similar to T6 | Mainly used where bending is limited or minor |

For critical bend operations, many users specify 6061‑T4 for forming, then perform artificial aging to reach T6-level properties after shaping.

Welding

| Attribute | Description |

|---|---|

| Weldability | Good by MIG/TIG with suitable filler (e.g., 4043, 5356) |

| Post-weld strength | Reduced in heat-affected zone compared to base T6/T651 |

| Corrosion behavior | Generally good; consider post-weld cleaning and coating |

When high post-weld strength is essential, design allowances or post-weld heat treatment may be necessary.

Machining

| Temper | Machinability Rating | Remarks |

|---|---|---|

| T4 | Fair | Softer, may produce more built-up edge |

| T6 | Very good | Clean cutting, good chip breaking |

| T651 | Excellent | Best for tight tolerances and flatness-critical parts |

Using T651 plates significantly reduces distortion in large pocketed or thin-wall machined components.

Corrosion Resistance and Surface Treatment

6061 aluminum exhibits good resistance to atmospheric and marine environments, especially when properly finished.

| Aspect | Performance / Option |

|---|---|

| Atmospheric corrosion | Good in urban and industrial conditions |

| Marine splash zone | Good with appropriate paint or anodizing |

| Anodizing | Suitable for decorative and hard anodizing |

| Painting & coating | Accepts powder coating, liquid painting, and conversion coatings |

For outdoor and marine applications, a combination of 6061 plate plus anodizing or coating extends service life and maintains appearance.

How to Select the Right 6061 Temper

| Design Priority | Suggested Choice | Reason |

|---|---|---|

| Maximum strength, general use | 6061‑T6 | Established standard for strong structural parts |

| High strength + minimal distortion | 6061‑T651 | Stress relief for machining-intensive components |

| Tight bends / deep drawing | 6061‑T4 | Higher ductility and formability |

| Welded structures with machining | 6061‑T6 / T651 | Good balance of weldability and post-weld machining |

https://www.aluminumplate.net/a/t4-t6-t651-6061-aluminum-sheet-plate.html