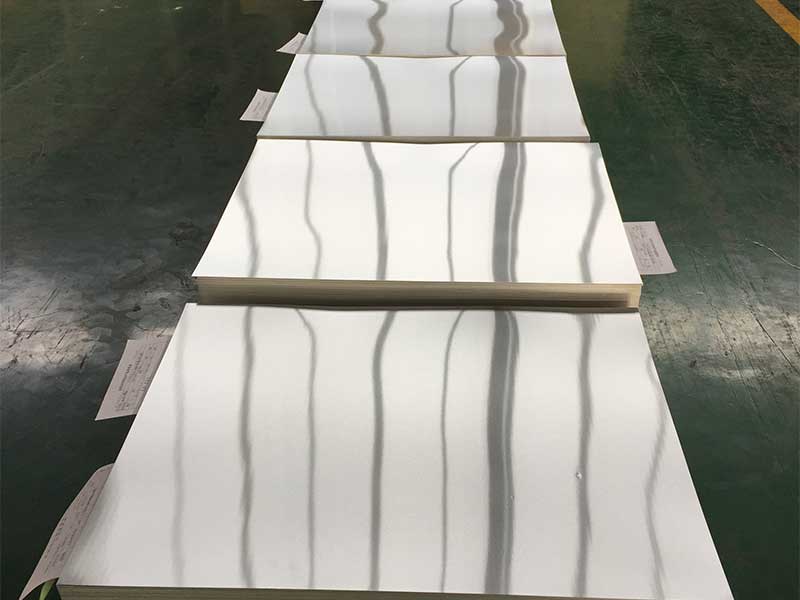

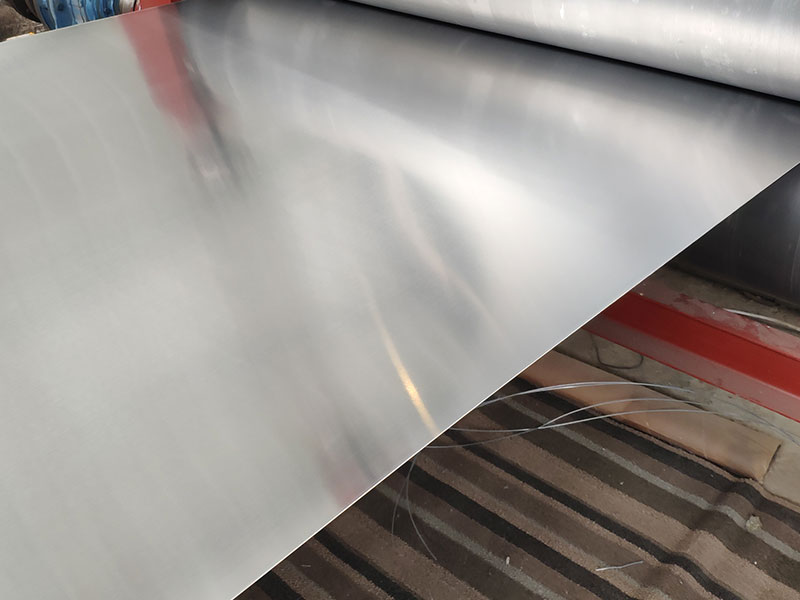

1050 h14 aluminium plate

The 1050 H14 aluminium plate is a widely used material characterized by its excellent corrosion resistance, high thermal and electrical conductivity, and lightweight property. This product is especially noted for its significant workability, making it ideal for various applications in a range of industries.

Features

- High Purity (99.5% Aluminium): The chemical purity lends itself to excellent thermal and electrical conductivities.

- Corrosion Resistance: The alloy exhibits excellent resistance to marine conditions and atmospheric environments, highlighting its suitability for outdoor applications.

- General Machinability: 1050 H14 is machinable and can easily be formed into complex shapes without compromising the physical properties of the material.

- Thermal Efficiency: Exceptional thermal conductivity makes it an ideal choice for heat exchange applications.

Applications

Given its advantageous attributes, 1050 H14 aluminium plate finds vast applications across numerous domains, particularly in:

- Manufacturing Processes: Components such as transformer housings and conductive plates where conductive cooling is required.

- Food and Chemical Industries: Hydroforming options enable the plate finding safe applications in food and liquid storage devices due to hygiene compliance.

- Architectural Applications: Its visual appeal and long-term durability make it suitable for decorative trim pieces and stylish façades.

- Electrical Applications: Power distribution equipment and electronic enclosures that exploit the conductive advantage.

Technical Specifications

| Property | Description |

|---|---|

| Alloy Designation | 1050 |

| Temper Designation | H14 |

| Thickness Range | 0.2 mm to 100 mm |

| Width Range | 1.000 mm to 2.500 mm |

| Length Range | Up to 6.000 mm |

Chemical Composition

The material's chemical composition crucially influences performance and adaptability. The table below showcases the standard chemical properties of the 1050 H14 aluminium plate:

| Element | Percentage (%) |

|---|---|

| Aluminium (Al) | ≥ 99.50 |

| Iron (Fe) | ≤ 0.4 |

| Copper (Cu) | ≤ 0.05 |

| Magnesium (Mg) | ≤ 0.03 |

| Manganese (Mn) | ≤ 0.05 |

| Silicon (Si) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.05 |

| Other Elements | Total ≤ 0.15 |

Alloy Tempering Conditions

The temper designation for the 1050 H14 aluminium plate describes the recovery and strengthening of the alloy through processes ensuring enhanced mechanical performance after cold working:

| Temper | Description |

|---|---|

| H14 | Work-hardened and partially annealed, resulting in increased Yield Strength (high fatigue resistance) |

Mechanical Properties

The mechanical in variables define how the aluminium plate fits in specific management of designs and loads. Below is a typical variability function for the H14 condition:

| Property | Metric Units | Recognized Values |

|---|---|---|

| Ultimate Tensile Strength (UTS) | MPa (N/mm²) | 130-200 |

| Yield Strength | MPa (N/mm²) | 90-155 |

| Elongation at Break | % | 10-20% |

| Density | g/cm³ | 2.70 |

By focusing on higher-quality compositions, extensive potential application areas, and significant resistance to corrosion, the 1050 H14 aluminium plate continues to stand as an essential material well adapted for contemporary needs in multiple industries.

https://www.aluminumplate.net/a/1050-h14-aluminium-plate.html