Aluminum bottle caps

10/09 2025

Aluminum bottle caps are a prominent choice for sealing beverages and various other liquid products due to their exceptional performance, durability, and sustainability.

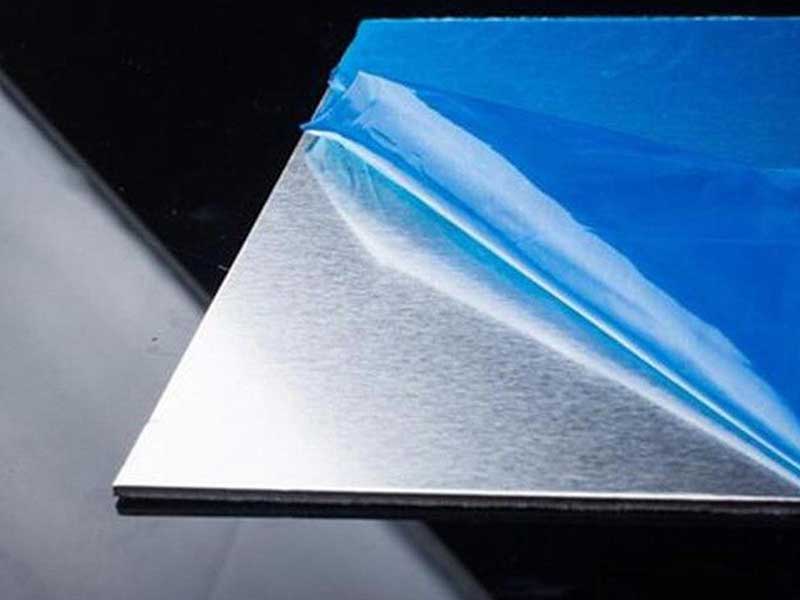

Aluminum bottle caps are closures made primarily from aluminum alloys, specifically engineered to protect the container’s contents from contamination, leakage, and oxidation while ensuring easy opening and resealing in many cases. The use of aluminum offers several benefits, including lightweight, corrosion resistance, ease of manufacturing, and recyclability.

2. Features

| Feature | Description |

|---|

| Material | High-grade aluminum alloys suitable for food and beverage sealing |

| Corrosion resistance | Strong resistance to corrosion, protecting the integrity of the container and product |

| Lightweight | Minimizes overall packaging weight, aiding transport efficiency |

| Formability | Excellent for shaping into precise lathe-turned or stamped components |

| Recyclability | 100% recyclable, supporting sustainability efforts |

| Barrier properties | Good seal that prevents oxygen and moisture ingress, maintaining product freshness |

| Customizability | Can be embossed, printed, or colored to meet branding requirements |

| Safety Features | Designed to prevent tampering with and secure sealing |

3. Chemical Composition

Aluminum bottle caps are generally manufactured from alloys primarily in the 1000, 3000, or 5000 series due to their striking balance between strength, corrosion resistance, and workability. Below is a representative chemical composition of a standard aluminum alloy used for bottle caps, commonly Alloy 3105-H19:

| Element | Percentage (%) | Remark |

|---|

| Aluminum (Al) | Balance (~96.8–97.8) | Base metal |

| Manganese (Mn) | 0.5 – 1.0 | Improves corrosion resistance and strength |

| Iron (Fe) | Up to 0.7 | Impurity |

| Silicon (Si) | Up to 0.3 | Increased strength |

| Copper (Cu) | Up to 0.1 | Strength and workability component |

| Zinc (Zn) | Up to 0.2 | Impurity |

| Titanium (Ti) | Up to 0.03 | Grain refinement |

| Others | Trace | |

4. Mechanical Properties

| Property | Typical Values | Standard Test Method |

|---|

| Tensile Strength | 130 – 160 MPa | ASTM B209 |

| Yield Strength | 55 – 110 MPa | ASTM B209 |

| Elongation (%) | 12 – 22 % | ASTM E8 |

| Hardness (Brinell) | 40 – 60 HB | ASTM E10 |

| Density | ~2.7 g/cm³ | ASTM B311 |

5. Technical Specifications

| Parameter | Typical Values | Notes |

|---|

| Cap Diameter | 26 – 44 mm | Standard sizes for beverages |

| Thickness | 0.15 – 0.30 mm | Depending on required mechanical strength |

| Coating | Food-safe lacquers | To prevent metal interaction with liquids |

| Sealing Type | Liner-based or cold form seals | Guarantees airtight and moisture-proof seal |

| Operating Temperature Range | -40°C to 90°C | Suitable for refrigerated and room temperature storage |

| Opening Torque | 0.5 – 4 Nm | Varies based on cap design and application |

6. Performance Characteristics

- Sealability: Aluminum bottle caps deliver exceptional sealing properties essential for beverages such as carbonated drinks, juices, wine, and distilled spirits, ensuring product longevity and safety.

- Corrosion Resistance: Their resistance prevents collapse or contamination when exposed to acidic or alkaline solutions within bottles.

- Lightweight Design: Helps reduce shipping costs and the carbon footprint.

- Thermal Resistance: Performs well under temperature variations during storage and pasteurization.

- Custom Branding: Thanks to excellent malleability and surface treatment, caps can carry logos, inscriptions, or safety information for consumer recognition.

7. Applications

| Industry | Use Case | Typical Containers |

|---|

| Beverage | Sealing for soda, water, juices, alcohols | Glass and plastic bottles |

| Pharmaceutical | Sealing solutions and syrups where hygiene is paramount | Medicine and health supplement bottles |

| Food | Bottled sauces, oils, and condiments | Glass bottles and jars |

| Cosmetics | Perfumes, essential oils, and lotions | Small glass and plastic containers |

| Chemical industry | Specialty chemicals requiring sealed containers | Small packaging bottles |

- Enhanced Product Protection: Maintains the original flavor and bio-properties of beverages and consumables.

- Environmentally Friendly: Fully recyclable and competitively energy efficient to produce.

- Cost Effective: Reduced material costs with superior mechanical performance.

- Branding & Customization: Opportunities to improve market identity with customized cap finishes.

- User Convenience: Easy twisting or pressing motion for consumers to open.

https://www.aluminumplate.net/a/aluminum-bottle-caps.html

Related Products

Related Blog