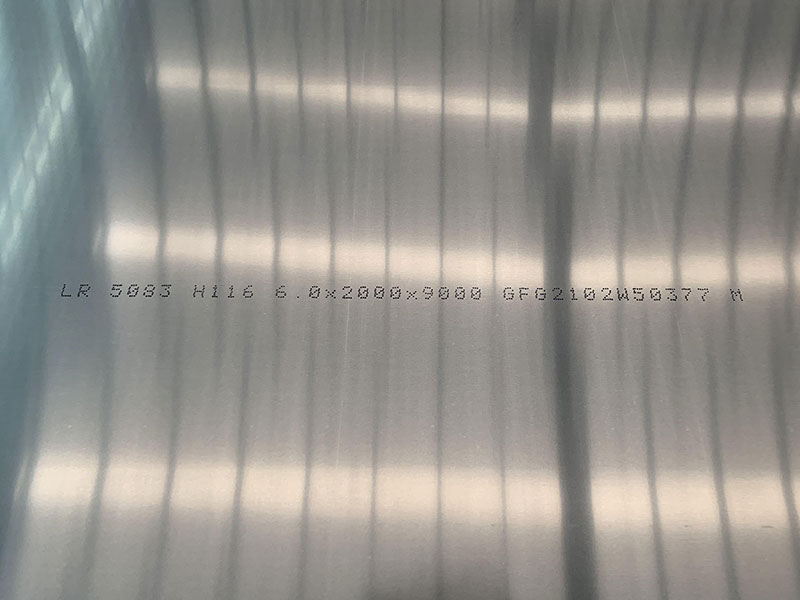

Marine Aluminum Sheet A5052 H32 H34 H36

Marine Aluminum Sheet A5052 is widely regarded as one of the best materials for marine environments due to its excellent corrosion resistance, outstanding mechanical strength, and good weldability. Manufactured primarily from aluminum, magnesium, and chromium, this alloy offers a reliable solution for a range of demanding applications—especially in marine and industrial settings.

A5052 is an aluminum-magnesium alloy known for its resilience against seawater corrosion. It is favored in settings where lightweight but durable materials are critical. Marine sheet qualities involve good workability, a long service life in wet and saline conditions, and substantial tensile strength.

Each temper state – H32, H34, and H36 – describes a level of strain hardening and thermal equilibrium to optimize physical properties suited for various load-bearing maritime applications.

Temper Designations: H32, H34, and H36

| Temper | Description | Typical Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| H32 | Strain hardened and stabilized, moderate hardness | 215 - 260 | 10 - 12 |

| H34 | Strain hardened and stabilized, higher hardness | 235 - 280 | 8 - 10 |

| H36 | Strain hardened and partially annealed | 260 - 300 | 6 - 8 |

- H32 supplies a good balance between stiffness and formability, commonly used in moderately stressed structures.

- H34 suits applications where enhanced strength with some ductility is desired.

- H36 is preferred in more rigid components, maximizing tensile strength with moderate flexibility.

Functional Characteristics

Marine Aluminum A5052 exhibits multiple properties specifically tuned for amphibiological challenges:

- Excellent Corrosion Resistance: The magnesium content increases resistance to seawater and industrial atmospheres.

- High Cracking and Surface Strength: Ideal for sustained tension and demanding environmental stress.

- Superior Weldability & Formability: Can be welded using TIG or MIG with ease, expanded into complex shapes or bent without surface defects.

- Anti-Oxidizing Element Composition: Chromium addition significantly reduces surface oxidation during operations.

Chemical Composition

| Element | Min (%) | Max (%) |

|---|---|---|

| Aluminum (Al) | Balance | - |

| Magnesium (Mg) | 2.2 | 2.8 |

| Chromium (Cr) | 0.15 | 0.35 |

| Iron (Fe) | - | 0.4 |

| Copper (Cu) | - | 0.1 |

| Manganese (Mn) | - | 0.1 |

| Silicon (Si) | - | 0.25 |

| Zinc (Zn) | - | 0.1 |

The strictly controlled composition maintains a consistent resistance to corrosion while preserving structural integrity and weld compatibility.

Technical Specifications

| Parameter | A5052 H32 | A5052 H34 | A5052 H36 | Unit |

|---|---|---|---|---|

| Ultimate Tensile Strength | 215 – 260 | 235 – 280 | 260 – 300 | MPa |

| Yield Strength (0.2% offset) | 140 – 190 | 155 – 205 | 180 – 225 | MPa |

| Elongation | 10 – 12 | 8 – 10 | 6 – 8 | % |

| Hardness (Brinell) | 75 – 90 | 85 – 100 | 90 – 105 | HB |

| Density | 2.68 | 2.68 | 2.68 | g/cm³ |

| Thermal Conductivity | 138 | 138 | 138 | W/m·K |

| Melting Point | 607 – 649 | 607 – 649 | 607 – 649 | °C |

Common Applications in Marine and Other Industries

Marine Aluminum A5052 sheets service a vital role across applications where corrosive exposure and mechanical stresses occur:

- Shipbuilding and Boats: Lightweight hulls, decks, superstructures, and bulkheads maximize fuel efficiency and sustain ocean saltwater.

- Marine Tanks and Pipelines: Resistant to seawater and chemical storage tank erosions, ensuring project longevity.

- Offshore Equipment: Durable and corrosion-resistant frames, platforms, and joint fittings withstand harsh offshore drilling conditions.

- Automotive Industry: Body panels, truck fuel tanks, and trailers employ this sheet for reduced weight and enhanced durability.

- Civil and Architectural: Decorative panels, roofing, and curtain walls exposed to coastal environments benefit from its corrosion resistance.

- Food and Chemical Processing: The chemical inertness suits tanks and machinery diverse from food-grade aluminum containers to chemically aggressive environments.

By selecting different temper options such as H32 through H36, users optimize strength and ductility according to fabrication and use-case requirements.

Implementation Standards

Manufacturing of A5052 marine aluminum sheets follows these widely accepted standards ensuring quality and interoperability internationally:

| Standard | Description |

|---|---|

| ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| AMS-4015 | Castings, Aluminum Alloy (A 4XX.X Series) |

| EN 485-2 | Aluminum and Aluminum Alloys - Sheet, Strip, and Plate - Part 2: Mechanical properties |

| ISO 6361 | Wrought aluminum and aluminum alloy sheets, strips, and plates |

These specifications ensure the chemical uniformity, mechanical consistency, and compliance with marine-grade durability.

How to Choose the Right Temper Grade

- If your project demands formability combined with decent strength and corrosion resistance, H32 is a reliable choice.

- For components requiring a completion balance of tighter mechanical strength without sacrificing bending capability, H34 fits most use cases.

- When stiffness and maximum strength take precedence—for example in structural supports and stress-intensive fittings—H36 is suitable.

Consult with material engineers to ensure correct temper selection aligns with welding, forging, or machining needed.

Final Thoughts

Marine Aluminum Sheet A5052 in H32, H34, and H36 tempers remains a top contender for high-performance material applications subjected to harsh marine conditions. Its corrosion resistance, alloy stability, and mechanical strength fulfill contemporary engineering needs, from naval architecture to offshore infrastructures.

When considering longevity, reduced maintenance, and environmental endurance, investing in A5052 sheets offers superior value. Equip your fleet or project with this proven material and leverage the comprehensive strengths of each available temper to meet your operational goals precisely.

https://www.aluminumplate.net/a/marine-aluminum-sheet-a5052-h32-h34-h36.html