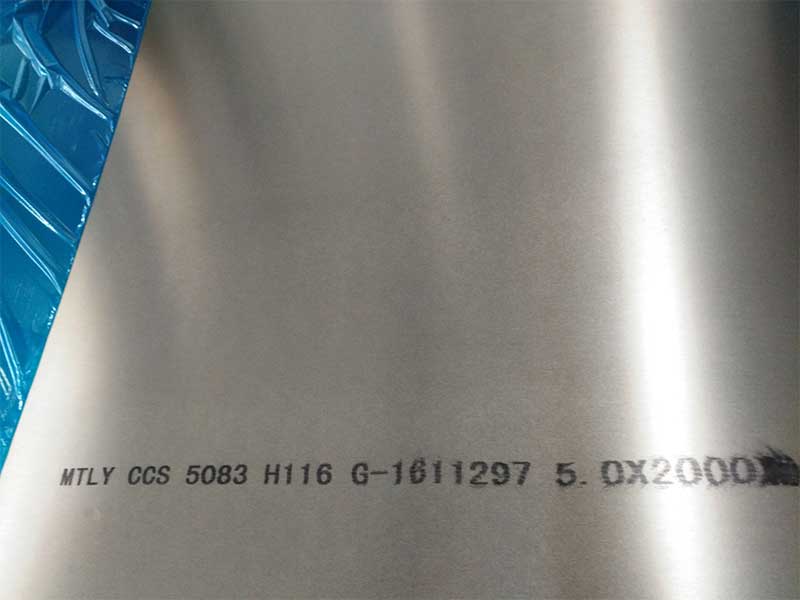

ASTM 5052 5083 Custom Aluminum Alloy Plate

Aluminum alloy plates 5052 and 5083 are non-heat-treatable alloys in the 5xxx series, alloyed primarily with magnesium. They are well known for their excellent corrosion resistance, good weldability, formability, and favorable strength-to-weight ratios. These properties make them suitable for marine, transportation, pressure vessels, architectural, and general fabrication uses.

- ASTM 5052: Often used where formability and moderate strength with excellent corrosion resistance are required (e.g., fuel tanks, marine components, general sheet/plate).

- ASTM 5083: Known for higher strength and superior corrosion resistance in marine environments, commonly used in shipbuilding, offshore structures, and cryogenic applications.

Functions and Advantages

- Excellent corrosion resistance in marine and chemical environments.

- Good weldability with most common welding processes (MIG/GMAW, TIG/GTAW, friction stir welding).

- High strength-to-weight ratio; 5083 has higher strength than 5052.

- Good formability and finishability (especially 5052).

- Good fatigue resistance and crack resistance, particularly in 5083.

- Non-heat-treatable — strength controlled by cold working (strain hardening) and alloy composition.

Typical Applications

- Marine structures: hulls, decks, superstructures (5083 preferred).

- Shipbuilding and boatbuilding components.

- Pressure vessels and cryogenic tanks (5083 used for low-temperature toughness).

- Transportation components: truck bodies, trailers, fuel tanks (5052 commonly used).

- Architectural panels, roofing, and cladding.

- Heat exchangers and chemical handling equipment.

- General fabrication parts requiring good forming and corrosion resistance.

Implementation Standards

Common standards and specifications that govern chemical, mechanical, and dimensional requirements include:

| Standard / Specification | Description |

|---|---|

| ASTM B209 | Aluminum and Aluminum-Alloy Sheet and Plate |

| ASTM B209M | Metric version of B209 |

| ASTM B928 | Standard Specification for Aluminum-Alloy Plate, Sheet, and Strip for Marine Service |

| AMS 4027 / QQ-A-250 | (Where applicable) Additional specialty aerospace/industrial specifications |

| EN 573 / EN 485 | European compositional and mechanical standards (for reference) |

| ISO 6361 | Wrought Aluminium and aluminium alloys — Sheets, strips and plates |

Note: Exact applicable standards may vary by customer requirement, thickness, and end-use; consult the order/spec for precise requirements.

Alloy Chemical Composition

The following tables show typical chemical composition ranges for 5052 and 5083 aluminum alloys (wt.%). These follow commonly accepted limits; refer to the applicable standard (e.g., ASTM B209/B928) for contractual limits.

5052 Chemical Composition (wt.%)

| Element | Typical Range (wt.%) |

|---|---|

| Al | Balance |

| Mg | 2.2 – 2.8 |

| Cr | 0.15 – 0.35 |

| Mn | 0.10 (max) |

| Fe | 0.4 (max) |

| Si | 0.25 (max) |

| Cu | 0.10 (max) |

| Zn | 0.25 (max) |

| Ti | 0.15 (max) |

| Others (each) | 0.05 (max) |

| Others (total) | 0.15 (max) |

5083 Chemical Composition (wt.%)

| Element | Typical Range (wt.%) |

|---|---|

| Al | Balance |

| Mg | 4.0 – 4.9 |

| Mn | 0.40 – 1.0 |

| Cr | 0.05 – 0.25 |

| Fe | 0.4 (max) |

| Si | 0.4 (max) |

| Cu | 0.25 (max) |

| Zn | 0.25 (max) |

| Ti | 0.15 (max) |

| Others (each) | 0.05 (max) |

| Others (total) | 0.15 (max) |

Temper and Heat Treatment Conditions

These alloys are non-heat-treatable; mechanical properties are achieved primarily via cold working (strain hardening). Common temper designations include O (annealed) and H variants (H1x, H3x, H4x) indicating strain hardening and/or controlled thermal treatments.

Common Tempers and Meanings

| Temper | Description |

|---|---|

| O | Annealed (softest, maximum formability) |

| H1 | Strain-hardened only (no thermal treatment) |

| H12 | Quarter hard (approx. H1 but specific degree) |

| H14 | Half hard |

| H16 | Three-quarter hard |

| H18 | Full hard |

| H111 | Slightly strain hardened (permanent set) |

| H116 / H321 / H321 variants | Strain-hardened and stabilized for improved resistance to sensitization (commonly used for 5083 in marine/shipbuilding) |

Note: Specific H-numbers and suffixes can vary by region/standard. 5083-H116 is a frequently specified temper for marine applications for excellent corrosion and mechanical properties.

Mechanical Properties

Mechanical characteristics depend on alloy, temper, and thickness. Below are typical ranges; project specifications must be checked for contractual values.

5052 Typical Mechanical Properties (approx.)

| Property | O Temper | H32 / H34 (example) |

|---|---|---|

| Tensile strength (MPa) | 110 – 135 | 220 – 260 |

| Yield strength (0.2% offset) (MPa) | 30 – 50 | 120 – 180 |

| Elongation (%) | 10 – 25 | 6 – 12 |

| Hardness (Brinell, HB) | ~25 – 40 | ~45 – 70 |

5083 Typical Mechanical Properties (approx.)

| Property | O Temper | H111 / H116 (example) |

|---|---|---|

| Tensile strength (MPa) | 275 – 350 (depending on temper) | 300 – 380 |

| Yield strength (0.2% offset) (MPa) | 125 – 200 | 215 – 305 |

| Elongation (%) | 10 – 20 | 10 – 16 |

| Hardness (Brinell, HB) | ~60 – 90 | ~70 – 100 |

Values above are indicative; confirm with mill certificates and relevant spec for exact figures.

Physical Properties

| Property | 5052 | 5083 |

|---|---|---|

| Density (g/cm³) | 2.68 | 2.66 – 2.7 |

| Thermal conductivity (W/m·K) | ~138 | ~120 – 130 |

| Electrical conductivity (% IACS) | ~33 – 35 | ~28 – 34 |

| Melting point (°C) | ~607 – 660 (alloyed range) | ~590 – 645 (alloyed range) |

Fabrication Characteristics

- Forming: 5052 has excellent formability (especially O temper); 5083 offers good formability but less than 5052 in harder tempers.

- Welding: Both alloys weld well with common fusion and solid-state techniques. Use appropriate filler (e.g., 5356 for 5xxx alloys) to maintain corrosion resistance and strength.

- Machining: Machining is moderate; tooling considerations similar to other aluminum alloys (higher feeds, sharp tools).

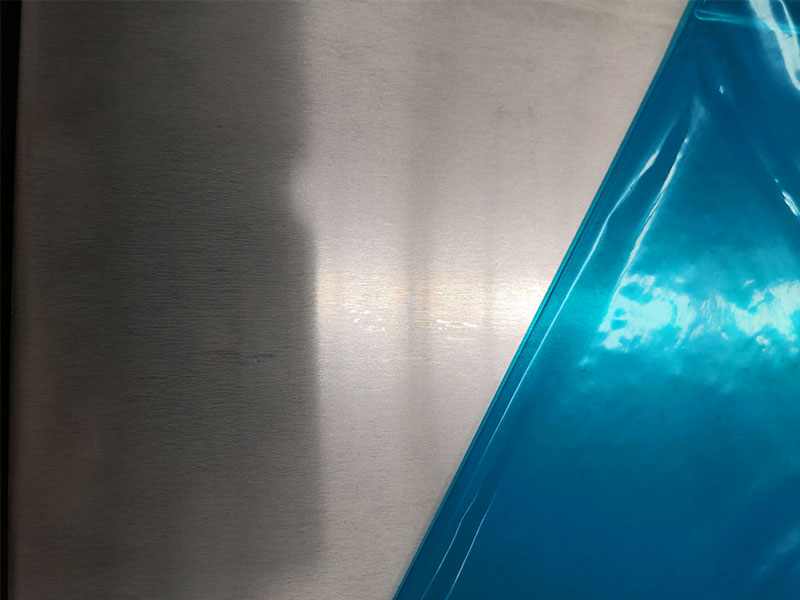

- Surface Finishing: Good for anodizing, painting, and coating; pre-treatment recommended for consistent results.

- Joining: Riveting, adhesive bonding, and mechanical fastening widely used.

Corrosion Resistance and Environmental Performance

- Excellent resistance to seawater and marine atmospheres; 5083 is preferred for harsher marine exposures.

- Good resistance to industrial chemicals and atmospheric corrosion.

- Susceptible to galvanic corrosion when in contact with more noble metals; use insulating materials or compatible fasteners/coatings.

- Sensitization (intergranular corrosion) can occur in 5xxx alloys when exposed to elevated temperatures (~65–200°C) for prolonged periods. Stabilized tempers (e.g., H116, H321 variants) reduce susceptibility.

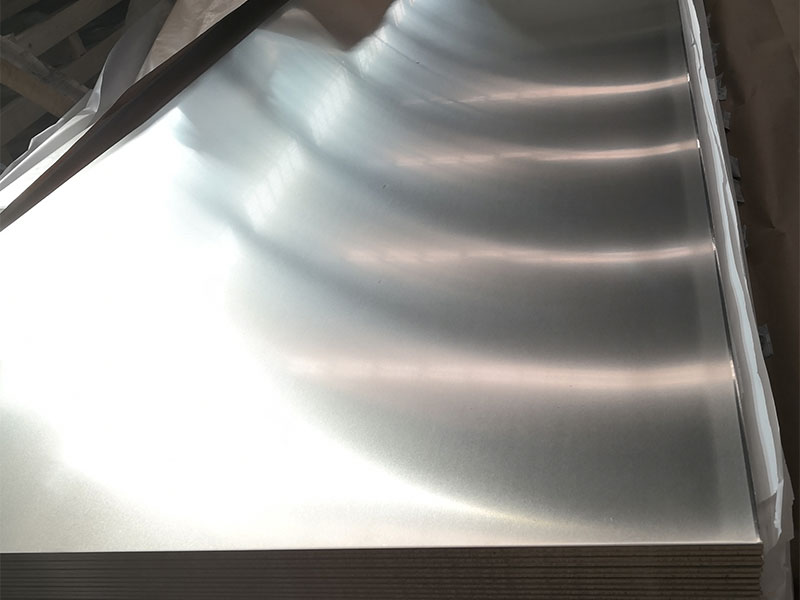

Typical Product Forms, Sizes, and Thickness Ranges

| Product Form | Typical Thickness Range |

|---|---|

| Plate | 3 mm to 200 mm (varies by mill capability) |

| Sheet | 0.2 mm to 6 mm (for thinner 5052) |

| Coils | 0.2 mm to 6 mm (sheet coils) |

| Cut-to-size plates | Custom per order |

Mill-specific limits apply. Standard widths and lengths depend on production processes and customer requirements.

Quality Control and Testing

Common tests and documentation provided:

- Chemical composition analysis (spectrometric)

- Mechanical testing (tensile, yield, elongation)

- Hardness testing (HB)

- Ultrasonic testing or eddy current for internal defects (on request)

- Surface quality inspection and dimensional tolerances

- Mill Test Certificate (MTC) per ASTM or customer spec

- Salt spray and corrosion testing (on request)

Typical Filler Metals and Welding Guidelines

- Recommended filler for welding 5052 and 5083: 5356 (Al-Mg) consumables for filler metal strength and corrosion resistance.

- Preheat is generally not required; avoid excessive heat to reduce risk of sensitization.

- Post-weld heat treatment is generally not used (non-heat-treatable alloys); control welding parameters to minimize distortion.

- Use appropriate backing, purge, and shielding gas for TIG/MIG welding to ensure sound welds.

| Feature | 5052 | 5083 |

|---|---|---|

| Primary use | Formable panels, fuel tanks, general fabrication | Marine hulls, shipbuilding, offshore, cryogenic tanks |

| Mg content | ~2.2–2.8% | ~4.0–4.9% |

| Strength | Moderate | Higher |

| Corrosion resistance | Excellent | Excellent, superior in seawater |

| Formability | Better | Good (tempers affect formability) |

| Weldability | Good | Good (common for structural welding) |

| Common tempers | O, H32, H34, H111 | O, H111, H116 (marine) |

Ordering and Customization Options

- Custom thicknesses, plate sizes, cut-to-length, edge preparation, and surface treatments (bright annealed, mill finish, sanded, anodized).

- Certification: supply MTC per ASTM/EN/ISO or customer-specific testing/certification.

- Packing: seaworthy packing for international shipment, protective films, wooden crates, or palletized bundles.

Notes on Handling and Storage

- Store plates in a clean, dry environment to minimize contamination.

- Use non-ferrous slings or protective pads to avoid scratches and galvanic contact.

- Protect surfaces with interleaving paper, polyethylene film, or VCI (vapor corrosion inhibitors) for long storage or transit.

https://www.aluminumplate.net/a/astm-5052-5083-custom-aluminum-alloy-plate.html