Anodized aluminum sheet alloy 1060

Anodized Aluminum Sheet Alloy 1060: When Purity Becomes a Design Tool

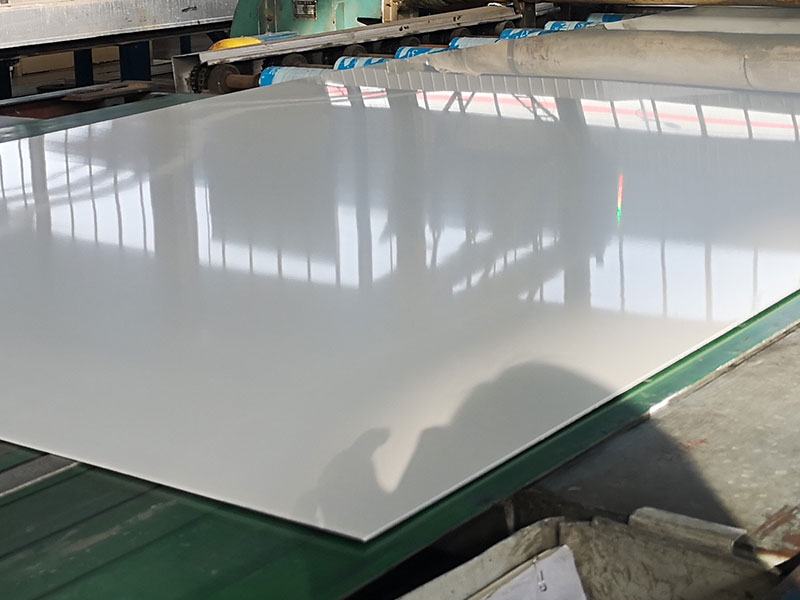

Anodized aluminum often gets described in surface terms: "good finish," "nice color," "corrosion resistant." Alloy 1060 changes that conversation. Because 1060 is a high‑purity aluminum (typically around 99.6% Al), it behaves less like a "strong structural metal" and more like a reliable canvas for anodizing. If your end product depends on appearance consistency, predictable oxide growth, and stable performance in daily environments, anodized 1060 aluminum sheet is one of the most straightforward, low‑risk choices you can specify.

What "1060" Really Means for Anodizing

All aluminum alloys can be anodized, but not all anodize the same way. Alloying elements that improve strength often introduce anodizing complications: grayish tone, uneven color absorption, and higher risk of visual inconsistency. Alloy 1060 sits at the opposite end of that tradeoff.

Because the alloy contains minimal additions (mainly small amounts of Si and Fe), the anodic oxide film tends to form more uniformly. That translates into stable gloss control, clearer bright finishes after polishing, and more consistent dye results, especially in light colors where any variation becomes obvious.

Typical Product Parameters Customers Actually Ask About

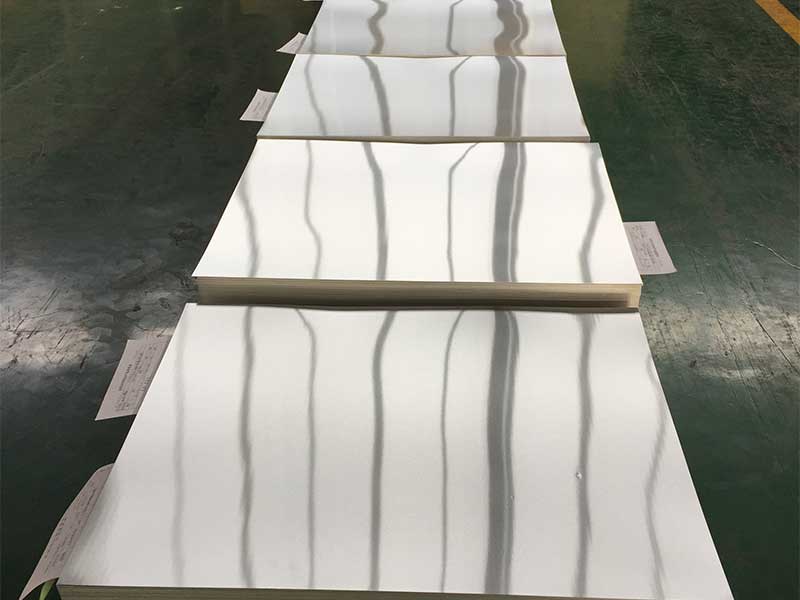

Practical buying decisions usually come down to dimensions, tolerances, anodizing type, and temper condition. Below are common ranges and options used in production. Exact availability depends on mill capability and order volume.

Common thickness range

0.2 mm to 6.0 mm for most anodized sheet applications; thicker plate is possible but often treated as a different product category.

Common width and length

Width typically up to 1500 mm; length often 2000–6000 mm, with cut-to-size options.

Surface finishes before anodizing

Mill finish, brushed (hairline), bright/polished, satin, or chemically brightened depending on the required reflectivity and texture.

Anodizing types used with 1060 sheet

Decorative anodizing (Type II) is widely used for indoor and general-purpose outdoor products. Hard anodizing (Type III) can be done but is less common for sheet aesthetics and may shift color toward darker gray.

Film thickness (typical reference values)

Decorative anodizing often targets about 5–25 μm depending on use environment; hard anodizing commonly starts around 25 μm and can go higher. Thicker films generally improve wear and corrosion resistance but may reduce gloss and alter perceived color.

Standards and Implementation References

Different markets call out different specifications. Anodized 1060 aluminum sheet is frequently produced and inspected with reference to the following standards and frameworks:

Aluminum alloy designation and chemical composition

GB/T 3190, ASTM B209 (composition and general requirements for aluminum sheet), EN 573 (chemical composition series)

Sheet and plate dimensional/tolerance standards

ASTM B209, EN 485, GB/T 3880

Anodizing quality and film requirements

ISO 7599 (decorative anodizing on aluminum), ISO 10074 (hard anodizing), MIL-A-8625 (Type II and Type III process definitions widely referenced in engineering)

In real projects, customers often specify both the sheet standard and the anodizing standard, because the substrate quality and the oxide film performance are inseparable.

Temper Conditions: How 1060 Gets "Tuned" for Forming or Flatness

Since 1060 is not chosen for high strength, temper selection is mainly about formability, flatness, and handling behavior during fabrication.

O temper (annealed)

Best for deep drawing, spinning, and aggressive forming where cracking risk must be minimized. If your part has tight radii or complex stamping, O temper is often the safest choice.

H12, H14, H16, H18 (strain-hardened series)

These tempers increase strength and stiffness progressively. H14 is a common balance for general sheet metal work. Higher H tempers can help reduce waviness and improve handling, but they reduce formability.

H24 and other "stabilized" tempers

Used where some strength is needed while retaining better forming characteristics compared to higher hard tempers. Availability may vary by supplier.

A useful rule: if the part is appearance-driven and requires post-anodize perfection, controlling temper helps control distortions during cutting, bending, and assembly.

Chemical Composition of Aluminum Alloy 1060

Below is a commonly referenced chemical composition table for AA 1060 (typical limits). Actual certificates of analysis should be confirmed per batch.

| Element | Composition (wt.%) |

|---|---|

| Aluminum (Al) | ≥ 99.60 |

| Silicon (Si) | ≤ 0.25 |

| Iron (Fe) | ≤ 0.35 |

| Copper (Cu) | ≤ 0.05 |

| Manganese (Mn) | ≤ 0.03 |

| Magnesium (Mg) | ≤ 0.03 |

| Zinc (Zn) | ≤ 0.05 |

| Titanium (Ti) | ≤ 0.03 |

| Others (each) | ≤ 0.03 |

| Others (total) | ≤ 0.10 |

This chemistry is the reason 1060 is so cooperative during anodizing. Low copper in particular helps corrosion resistance and supports a cleaner anodized appearance.

Material Properties and What They Mean in Use

Corrosion behavior

1060 already has good natural corrosion resistance due to its purity. Anodizing adds a controlled oxide layer, improving resistance further and making the surface easier to clean and maintain.

Electrical and thermal conductivity

High‑purity aluminum has excellent conductivity. If you need an anodized surface for insulation on the outside while still benefiting from aluminum's heat spreading, 1060 is a practical option in housings, lighting, and electronics-related panels. Note that anodic film itself is electrically insulating.

Strength and stiffness

1060 is not a high-strength alloy. If the part must carry loads, you may need thicker gauge, stiffening features, or a different alloy (such as 5052 or 6061). For decorative panels and formed enclosures, 1060 is often more than adequate.

The Anodizing Outcome: Color, Consistency, and "Surface Honesty"

Anodizing doesn't hide substrate defects; it highlights them. Scratches, roll marks, and local contamination can appear more visible after anodizing, especially on bright finishes. Alloy 1060 helps by being chemically consistent, but surface preparation still determines the final look.

If your product is meant to feel premium, the best results usually come from aligning three choices: a consistent base finish, a stable temper that forms without distortion, and an anodizing spec that matches the environment. For indoor decorative components, a moderate Type II film can look crisp and bright. For outdoor exposure, a thicker film and proper sealing improve durability and color retention.

Buying Notes That Reduce Production Risk

When sourcing anodized aluminum sheet alloy 1060, it helps to communicate performance needs in simple production language: intended forming method, expected exposure (indoor, outdoor, marine-adjacent), desired gloss level, and whether color matching across batches matters. If tight color control is required, it's wise to lock in anodizing line parameters, dye system, and inspection method with the finisher.

Why 1060 Anodized Sheet Is Still a Smart Choice

In a world of high-strength alloys and complex coatings, anodized 1060 aluminum sheet remains popular because it's predictable. It gives manufacturers a stable surface for branding, a clean look for consumer-facing parts, and a corrosion-resistant skin that doesn't demand heavy maintenance. Most importantly, it turns aluminum's natural strength-its ability to form a protective oxide-into a controlled, engineered finish that customers can see and trust.

https://www.aluminumplate.net/a/anodized-aluminum-sheet-alloy-1060.html