Alloy aluminum sheet and plate 5052 h32 5083 h112 5754 h32

12/31 2025

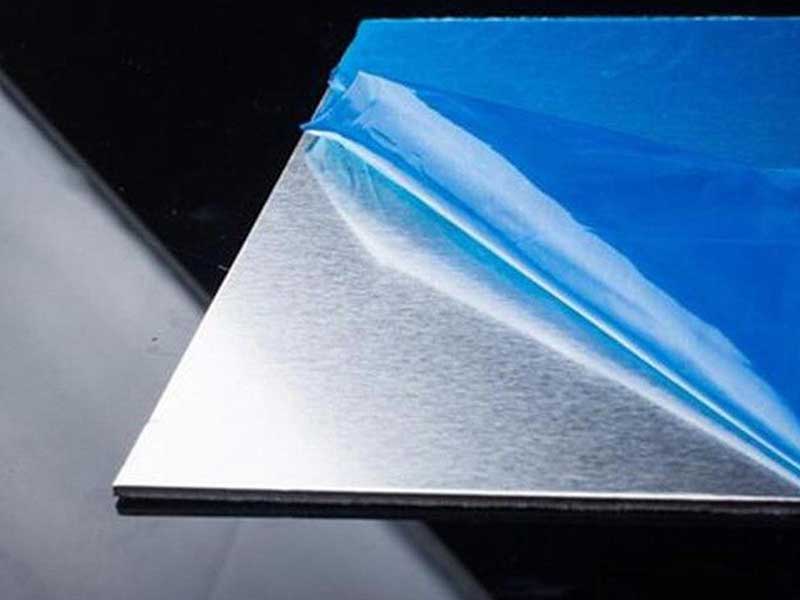

Aluminum–magnesium alloys such as 5052, 5083, and 5754 are among the most widely used non‑heat‑treatable alloys for sheet and plate. They combine medium to high strength with outstanding corrosion resistance and excellent formability, making them ideal for marine, transportation, architectural, and general engineering uses.

| Alloy | Temper | Strength Level | Main Features | Typical Forms |

|---|

| 5052 | H32 | Medium | Excellent formability, good weldability, very good corrosion resistance | Sheet, coil, medium-thickness plate |

| 5083 | H112 | High | High strength, superb marine corrosion resistance, good toughness | Heavy plate, marine plate, structural plate |

| 5754 | H32 | Medium | Good strength, very good corrosion resistance, good surface quality | Sheet, plate for automotive & building |

Chemical Composition

Values are typical ranges in weight percent (%). Actual limits may vary slightly with specification (ASTM, EN, etc.).

5052 H32 Chemical Composition

| Element | Content (%) |

|---|

| Mg | 2.2 – 2.8 |

| Cr | 0.15 – 0.35 |

| Mn | ≤ 0.10 |

| Fe | ≤ 0.40 |

| Si | ≤ 0.25 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.03 |

| Al | Balance |

5083 H112 Chemical Composition

| Element | Content (%) |

|---|

| Mg | 4.0 – 4.9 |

| Mn | 0.40 – 1.0 |

| Cr | 0.05 – 0.25 |

| Fe | ≤ 0.40 |

| Si | ≤ 0.40 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Al | Balance |

5754 H32 Chemical Composition

| Element | Content (%) |

|---|

| Mg | 2.6 – 3.6 |

| Mn | ≤ 0.50 |

| Cr | ≤ 0.30 |

| Fe | ≤ 0.40 |

| Si | ≤ 0.40 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.20 |

| Ti | ≤ 0.15 |

| Al | Balance |

Mechanical Properties & Technical Specifications

Values below are typical room‑temperature properties for common thickness ranges.

5052 H32 Sheet / Plate

| Property | Typical Value |

|---|

| Temper | H32 (strain-hardened, stabilized) |

| Tensile Strength (MPa) | 215 – 260 |

| Yield Strength (0.2% proof, MPa) | ≥ 160 |

| Elongation (A50, %) | 7 – 14 (depending on thickness) |

| Brinell Hardness (HBW) | ~ 60 – 70 |

| Density (g/cm³) | 2.68 |

| Modulus of Elasticity (GPa) | ~ 70 |

| Thermal Conductivity (W/m·K) | ~ 138 |

| Electrical Conductivity (% IACS) | ~ 35 |

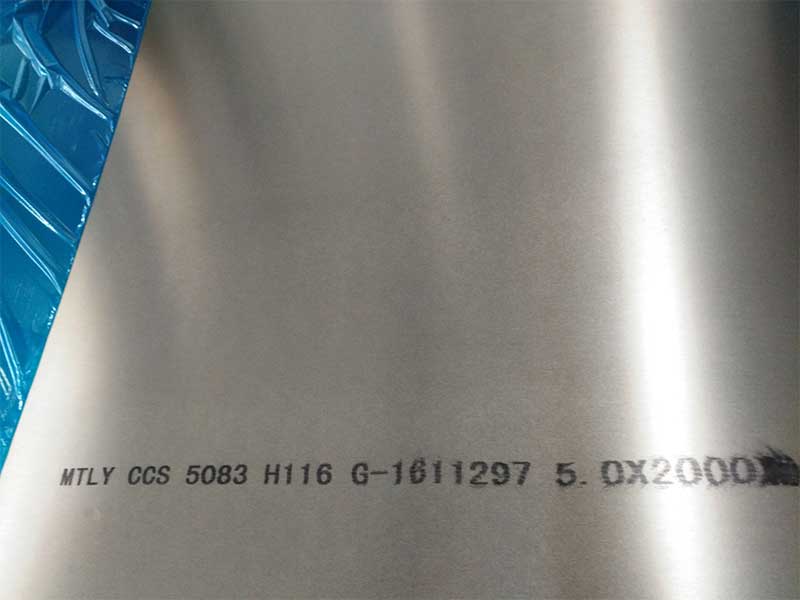

5083 H112 Plate

| Property | Typical Value |

|---|

| Temper | H112 (as-fabricated with slight work) |

| Tensile Strength (MPa) | 275 – 345 |

| Yield Strength (0.2% proof, MPa) | ≥ 125 – 215 (thickness dependent) |

| Elongation (A50, %) | 10 – 17 |

| Brinell Hardness (HBW) | ~ 75 – 90 |

| Density (g/cm³) | 2.66 |

| Modulus of Elasticity (GPa) | ~ 70 |

| Thermal Conductivity (W/m·K) | ~ 121 |

| Electrical Conductivity (% IACS) | ~ 28 |

5754 H32 Sheet / Plate

| Property | Typical Value |

|---|

| Temper | H32 |

| Tensile Strength (MPa) | 190 – 240 |

| Yield Strength (0.2% proof, MPa) | ≥ 130 |

| Elongation (A50, %) | 8 – 15 |

| Brinell Hardness (HBW) | ~ 60 – 70 |

| Density (g/cm³) | 2.67 |

| Modulus of Elasticity (GPa) | ~ 70 |

| Thermal Conductivity (W/m·K) | ~ 130 |

| Electrical Conductivity (% IACS) | ~ 30 |

Features of Each Alloy

5052 H32 – Formable, Weldable, Corrosion‑Resistant

| Feature Category | Description |

|---|

| Corrosion resistance | Very good in marine and industrial atmospheres, good resistance to salt spray |

| Formability | Excellent for bending, deep drawing, and rolling |

| Weldability | Suitable for TIG, MIG, and resistance welding |

| Surface finish | Smooth, suitable for anodizing and coating |

| Weight vs. strength | Good balance for lightweight structures |

5052 H32 is often selected where complex shapes and moderate strength are required, while maintaining resistance to moisture and atmospheric corrosion.

5083 H112 – High‑Strength Marine & Structural Plate

| Feature Category | Description |

|---|

| Strength | Among the highest strength non‑heat‑treatable Al–Mg alloys |

| Corrosion resistance | Outstanding in seawater and marine environments |

| Weldability | Very good, with limited loss of strength in the heat‑affected zone |

| Toughness | Good impact resistance, even at low temperatures |

| Dimensional stability | Suitable for thick plate and large panels |

5083 H112 is the go‑to alloy for high‑load marine structures, tankers, and pressure applications where both strength and corrosion resistance are critical.

5754 H32 – Versatile for Automotive & Architectural Use

| Feature Category | Description |

|---|

| Corrosion resistance | Very good resistance to seawater, industrial pollution, and road salt |

| Formability | Good for moderate forming and profiling |

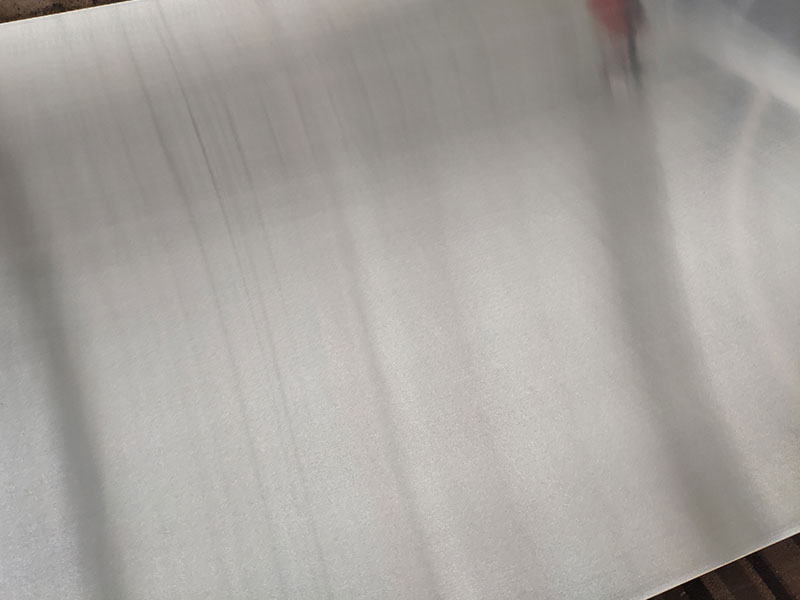

| Surface appearance | Stable, attractive surface quality; suitable for decorative finishes |

| Fatigue performance | Good for dynamically loaded parts |

| Compatibility | Widely used in European automotive and building standards |

5754 H32 is widely used where appearance, corrosion resistance, and moderate strength must be combined with reliable forming behavior.

Dimensional Range & Tolerances

Typical supply capabilities (may vary by mill and order):

| Parameter | 5052 H32 Sheet / Plate | 5083 H112 Plate | 5754 H32 Sheet / Plate |

|---|

| Thickness range (mm) | ~ 0.5 – 12 | ~ 4 – 120+ | ~ 0.7 – 10 |

| Width (mm) | Up to ~ 2000 | Up to ~ 2500 | Up to ~ 2000 |

| Length (mm) | Up to ~ 6000 (cut-to-length or coil) | Up to ~ 12000 for ship plate | Up to ~ 6000 |

| Flatness | As per ASTM/EN tolerances, improved flatness on request |

Comparison of Alloys – Quick Selection Guide

| Requirement / Priority | Recommended Alloy / Temper |

|---|

| Maximum corrosion resistance in seawater | 5083 H112, then 5754 H32 |

| Highest strength (non‑heat‑treatable) | 5083 H112 |

| Best for complex forming and deep drawing | 5052 H32 |

| Balance of strength and surface appearance | 5754 H32 |

| Heavy marine or cryogenic plate | 5083 H112 |

| General purpose, light marine or enclosure panels | 5052 H32, 5754 H32 |

Typical Applications

5052 H32 Applications

| Industry | Typical Uses |

|---|

| Marine | Small boat hulls, deck hardware, cabin panels, tool boxes |

| Transportation | Fuel tanks, truck bodies, bus panels, trailer siding |

| Enclosures | Electrical boxes, control cabinets, instrument panels |

| Consumer products | Kitchen equipment, refrigerators, furniture trim |

| General fabrications | Brackets, covers, signage, protective guards |

5052 H32 is chosen when designers need a medium‑strength alloy that can be bent, punched, and formed without cracking, while resisting everyday corrosion.

5083 H112 Applications

| Industry | Typical Uses |

|---|

| Shipbuilding | Hull plating, decks, bulkheads, superstructures, ramps |

| Offshore & marine | Platforms, gangways, support structures, fender systems |

| Transportation | LNG and chemical tankers, railway tank cars, refrigerated trailers |

| Pressure equipment | Cryogenic vessels, pressure tanks, storage containers |

| Defense | Naval vessels, armored vehicle components (where specified) |

5083 H112 is a reference grade for high‑strength marine and cryogenic structures, often specified in classification society rules for ship and offshore construction.

5754 H32 Applications

| Industry | Typical Uses |

|---|

| Automotive | Inner body panels, floor panels, wheel housings, fuel tanks |

| Rail & bus | Interior linings, steps, flooring, side panels |

| Building & construction | Facades, window frames, roofing sheets, decorative panels |

| Food & chemical | Storage tanks, silos, clean‑room panels |

| General engineering | Platforms, stair treads, patterned (tread) plate bases |

5754 H32 is popular where an attractive surface must withstand outdoor exposure and mechanical use, such as vehicle bodies and architectural elements.

Processing, Fabrication & Surface Treatment

| Process Area | 5052 H32 | 5083 H112 | 5754 H32 |

|---|

| Cutting | Shearing, sawing, laser, waterjet | Sawing, plasma, laser, waterjet | Shearing, sawing, laser, waterjet |

| Forming / bending | Excellent | Good (larger radii on thicker plate) | Good |

| Welding | Very good (MIG/TIG) | Very good (MIG/TIG) | Very good |

| Machining | Fair to good | Fair | Fair to good |

| Anodizing / coating | Good decorative and protective | Mainly protective; appearance less critical | Good decorative and protective |

All three alloys are non‑heat‑treatable; they gain strength by cold working. They can be painted, powder‑coated, or anodized for enhanced appearance and durability.

Why Choose Alloy Aluminum Sheet and Plate 5052 H32 / 5083 H112 / 5754 H32

These three alloys cover a broad spectrum of engineering needs:

- 5052 H32 provides excellent formability and reliable corrosion resistance for general sheet fabrications.

- 5083 H112 delivers high strength and superior marine performance for heavy plate and structural components.

- 5754 H32 offers a balanced solution for automotive and architectural applications where appearance, corrosion resistance, and moderate strength are all important.

By combining these alloys within a single project—using 5083 for primary load‑bearing structures, 5754 for visible panels, and 5052 for formed details—designers can optimize performance, cost, and fabrication efficiency across the entire system.

5052

5083

5754

https://www.aluminumplate.net/a/alloy-aluminum-sheet-and-plate-5052-h32-5083-h112-5754-h32.html