1060 H14 H24 Aluminum Sheet

The 1060 H14 H24 Aluminum Sheet is a high-purity aluminum product known for its exceptional corrosion resistance, excellent electrical conductivity, and malleability. Commonly used in applications requiring lightweight and durable sheet metal, the 1060 aluminum alloy is popular across various industries including electrical, packaging, construction, and aesthetic decorative uses.

1060 refers to a commercially pure aluminum alloy with a minimum aluminum content of 99.6%. The designation belongs to the 1xxx series aluminum alloys, recognized primarily for their excellent corrosion resistance, workability, and welding characteristics but relatively lower strength compared to more heavily alloyed aluminum grades.

The temper designations H14 and H24 reflect different degrees of cold working and subsequent hardness and strength levels:

- H14: Partial hard temper with approximately 50% cold working.

- H24: Quarter hard temper with about 25% cold work.

Both tempers retain much of the metal's inherent ductility and corrosion resistance, with H14 being slightly stronger and harder than H24.

Chemical Composition

The chemical composition of the 1060 aluminum sheet alloy covers elemental percentages critical to its purity and overall physical behavior. The alloy's composition must conform to international standards (such as ASTM B209).

| Element | Content (%) Max / Min | Typical Range (%) |

|---|---|---|

| Aluminum (Al) | Balance | 99.60 – 99.85 |

| Copper (Cu) | Max 0.05 | ≤ 0.05 |

| Iron (Fe) | Max 0.35 | 0.10 – 0.30 |

| Manganese (Mn) | Max 0.03 | ≤ 0.03 |

| Silicon (Si) | Max 0.25 | 0.10 – 0.20 |

| Zinc (Zn) | Max 0.03 | ≤ 0.03 |

| Titanium (Ti) | Max 0.03 | ≤ 0.03 |

| Other Elements | each Max 0.03 | ≤ 0.03 |

| Other Elements | total Max 0.10 | ≤ 0.10 |

Note: The "balance" means remainder after accounting for measured impurities is aluminum.

Physical and Mechanical Properties

The following table compares the mechanical and physical properties of 1060 aluminum in H14 and H24 tempers:

| Property | Unit | 1060 H14 | 1060 H24 |

|---|---|---|---|

| Ultimate Tensile Strength | MPa | 100 – 130 | 95 – 115 |

| Yield Strength (0.2% offset) | MPa | 70 – 90 | 65 – 85 |

| Elongation (in 50 mm) | % | ≥ 12 | ≥ 18 |

| Hardness (Brinell) | HB | 30 – 40 | 25 – 35 |

| Density | g/cm³ | 2.71 | 2.71 |

| Electrical Conductivity | % IACS | 58 – 63 | 58 – 63 |

| Thermal Conductivity | W/(m·K) | ~220 | ~220 |

| Melting Point | °C | 645 – 660 | 645 – 660 |

Notes:

- The H14 temper enhances strength by cold working to about 50%, suitable where moderate strength with good formability is required.

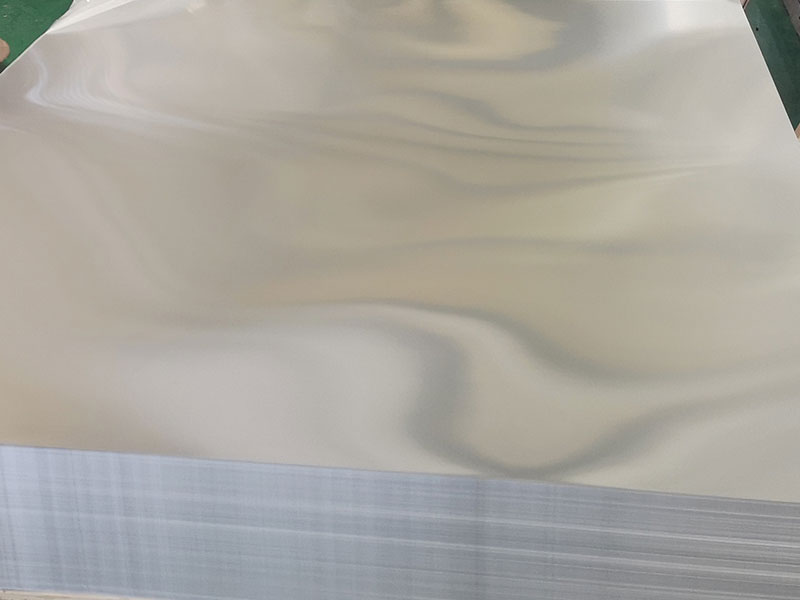

- The H24 temper involves less cold working and retains slightly better ductility, beneficial for bending and shaping operations with good surface finish requirements.

Features of 1060 H14 H24 Aluminum Sheets

- High Purity (≥ 99.6%): Outstanding corrosion resistance critical for exposure to most atmospheres and waters.

- Excellent Workability: Both H14 and H24 sheets possess good formability for bending, deep drawing, and spinning.

- Lightweight: With a density of just 2.71 g/cm³, great for weight-sensitive applications.

- Superior Electrical and Thermal Conductivity: Ideal for electronic and electrical applications.

- Non-Toxic & Eco-Friendly: Smooth anodizing process possible; reusable and recyclable.

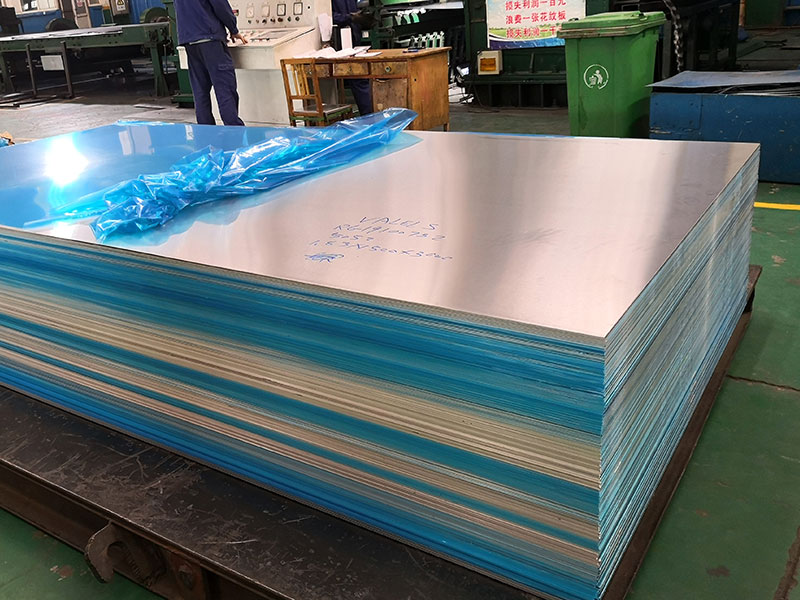

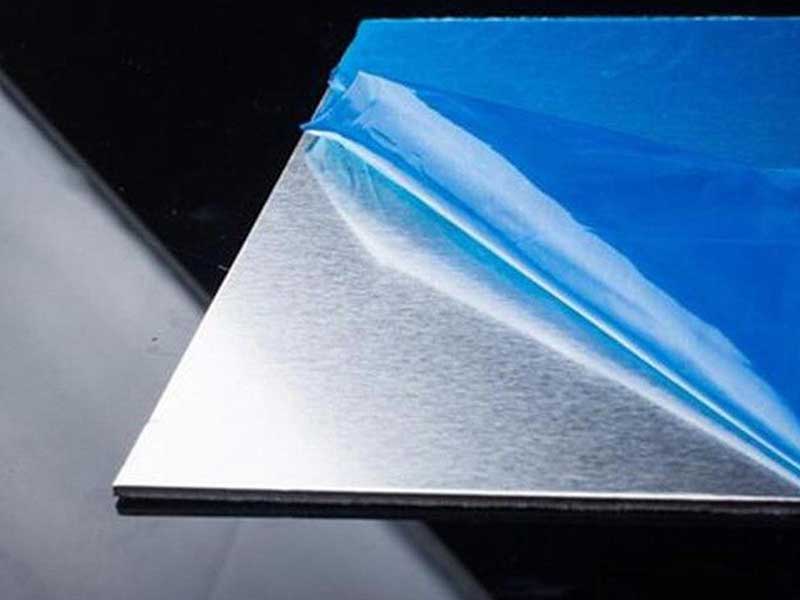

- Surface Quality: Uniform surface with excellent finish, suited for decorative and aesthetic uses.

- Non-Heat Treatable: Strength is improved mainly through cold working instead of heat treatments.

Common Applications of 1060 H14 H24 Aluminum Sheets

| Industry | Application |

|---|---|

| Electrical | Busbars, capacitors foil, wiring fences, heat sinks. |

| Packaging | Aluminum foil, food trays, and tubes (common in foil lamination given high purity and malleability). |

| Architecture & Construction | Cladding materials, roofing rolls, gutter presses for excellent corrosion resistance. |

| Automotive | Decorative trim, heat shields |

| Chemical & Food | Tanks, silos, containers due to non-toxicity and resistance to chemicals. |

| Decorative Uses | Interior decoration, engraved signs, and nameplates with high surface finish. |

| Heat Exchangers | Due to good thermal conductivity, applications in air conditioning and refrigeration components. |

Processing and Fabrication Recommendations

- Cold Working: Both H14 and H24 are obtained through cold rolling processes imparting controlled strain and strength levels.

- Forming: Easy fabrication with stamping, bending, spinning while anodizing yields good appearance and corrosion protection if needed.

- Welding: Weldable by all common methods without strength degradation typical in alloy series despite cold work.

- Anodizing: Both tempers respond well and provide excellent corrosion protection with an aesthetic finish.

The 1060 H14 H24 Aluminum Sheet offers a unique blend of high purity, corrosion resistance, good strength (thanks to multiple temper options), and great ductility supporting a wide array of industrial applications. Whether chosen for electrical applications requiring exceptional conductivity or decorative architectural uses needing aesthetically smooth yet robust sheeting, the 1060 alloy delivers consistent performance, sustainable recyclability, and manufacturing flexibility.

For detailed technical queries, custom sizing requests, or ordering options, please feel free to contact our sales engineers, who specialize in aluminum alloy expertise.

https://www.aluminumplate.net/a/1060-h14-h24-aluminum-sheet.html