Aluminum Plate for Boat Building 5086 2mm 3mm 4mm

The Allure of Aluminum Plate 5086: A Shipbuilder's Perspective on the 2mm, 3mm, and 4mm Variants

The marine environment is one of the most demanding for materials, thanks to the juxtaposition of water, salt, and varying weather conditions. Among the materials prized for construction in this unforgiving arena, aluminum alloy, particularly the 5086 grade, stands out for its formidable capabilities and versatility.

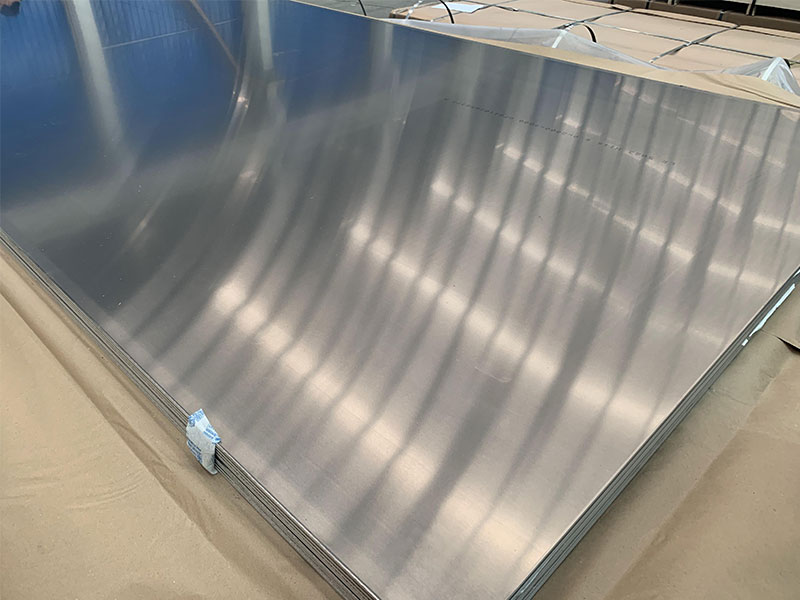

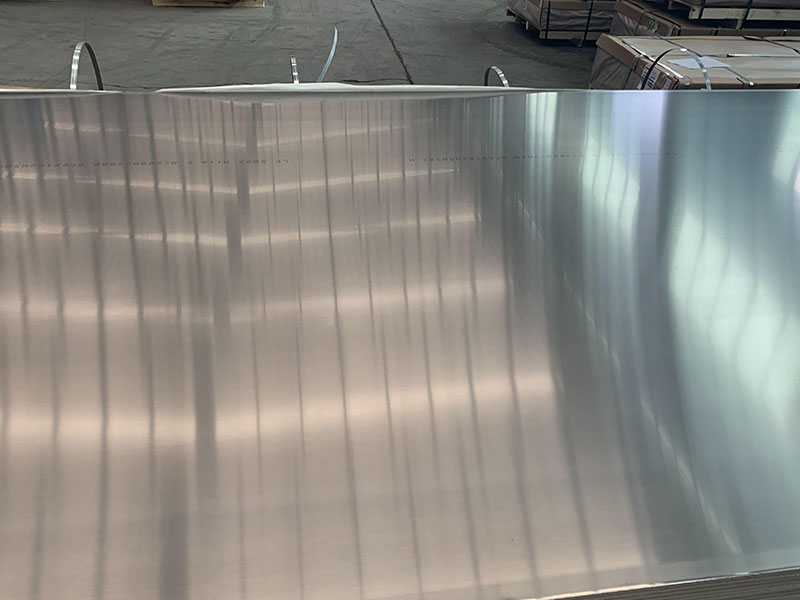

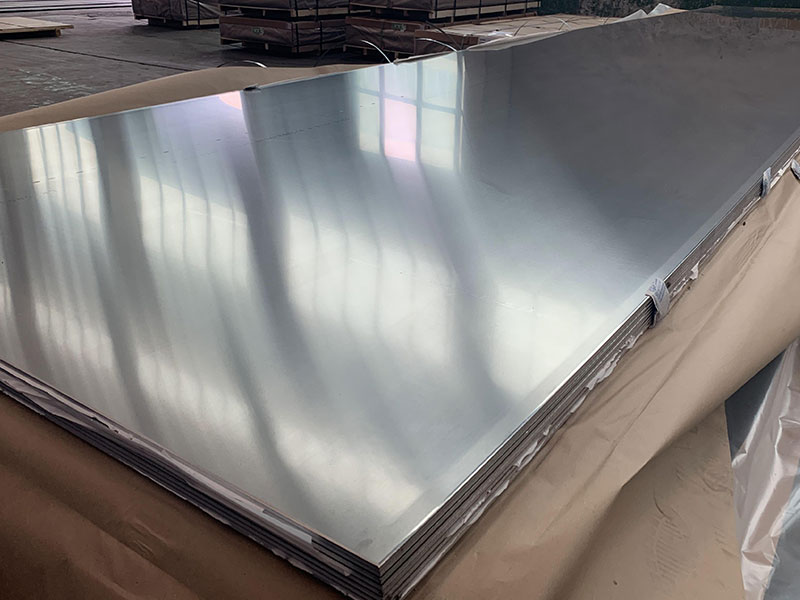

Working with 5086 aluminum plate in 2mm, 3mm, and 4mm thicknesses for boat building presents a unique set of considerations. The 5086 alloy's excellent strength-to-weight ratio and corrosion resistance are highly desirable, especially in marine environments. However, the thinner gauges (2mm and 3mm) require careful handling during fabrication to avoid bending or warping. We've found that pre-bending operations, especially on larger sheets intended for hull sections, are crucial to minimize distortion during welding. Furthermore, proper edge preparation is paramount for achieving strong, reliable welds, as thinner plates are more susceptible to weld penetration issues if not handled correctly. We often see issues with inexperienced welders burning through the thinner plates, necessitating more material and increased labor costs.

Beyond fabrication, the choice of thickness depends heavily on the application. 2mm might suffice for smaller boats or non-structural components, whereas 3mm and 4mm are more suitable for the hull and other high-stress areas of larger vessels. We've seen instances where cost-cutting measures led to the use of thinner plates than specified, resulting in premature cracking and failures in service. Therefore, careful consideration of the boat's design, intended use, and environmental exposure is crucial when selecting the appropriate plate thickness. Regular inspection for crevice corrosion, particularly in areas with poor drainage or trapped water, is also vital for ensuring the

5086 Alloy: The ‘Marine Grade’ Powerhouse

Before we move into the specifics, it's important to understand what makes 5086 a go-to material for marine applications. This aluminum alloy is part of the 5000 series, known for its high resistance to corrosion, which is crucial in the maritime industry where metal parts must withstand constant exposure to salty waters. The addition of magnesium provides 5086 with strength and weldability, making it easier for boat builders to work with while maintaining the integrity of the structure.

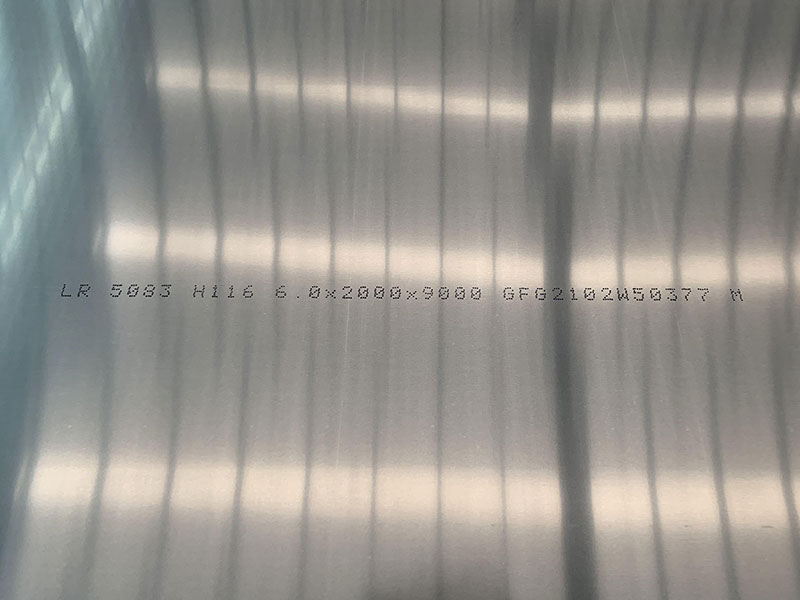

In terms of composition, 5086 typically includes aluminum (90% or above), magnesium (3.5%–4.5%), and small percentages of manganese, silicon, or copper. This precise mixture not only contributes to its strength but also facilitates good machinability, which can be vital during the fabrication process.

2mm Aluminum Plate: Lighter Designs, Specialized Applications

When we begin with the 2mm thickness, we find an elegant answer for certain specialized applications. Used primarily in components such as milled parts, cabin interiors, and intricate framework, the 2mm plate offers significant weight savings while still retaining strength relative to its thickness. For boat builders, this means the ability to maximize performance through reduced weight — an essential consideration if speed and fuel efficiency is on the agenda.

However, while the 2mm plate has advantages, its thinner profile is best utilized in applications that won't compromise integrity under stress or heavy load. It allows novice builders to experiment with lightweight designs that won't demand a heavy investment.

3mm Aluminum Plate: The Versatile Middle Ground

Stepping up to 3mm aluminum plate 5086 presents a well-balanced option that accommodates a wider range of applications. This thickness serves as a great compromise when additional structural resilience is required while maintaining a manageable weight.

Typical usages for this thickness include hull plating, deck structures, and other parts that are not subjected to significant stress but still require a strengthened elemental composition. Each plate can contribute both strength and weight efficiency in critical locomotion mechanisms or supporting structural elements of the boat. Furthermore, the extra thickness provides the added benefit of making cutting and welding easier for builders seeking to create complex designs without damaging their materials.

4mm Aluminum Plate: When Durability Meets Power

At 4mm, the aluminum plate 5086 reaches a level of durability that is especially advantageous for more intense marine applications. Vectoring strength hugely upward, this thickness is protective yet workable for a bottom falling lands, carry girder-like support structures, and major sections of fishing boats or larger vessels subjected to constant water and weather stress.

Shipbuilders gravitate toward 4mm plates when designing massive sea-going vessels, where sturdy foundation support and resilience against forces like waves or impacts is paramount. The added thickness means the plate’s surface area can endure blows or wear over time, an absolute necessity when reliability is a must.

An Ecological and Economic Perspective

Building boats with aluminum alloys like 5086 presents ecological advantages as well. Aluminum is highly recyclable, involving a lower carbon footprint when recycling compared to producing new metal. As ship builders increasingly embrace sustainable practices, selecting aluminum that effectively serves their marine needs while prioritizing environmental impact becomes essential.

Though some may argue that heavier materials ensure robustness around water, the truth shines through: selecting aluminum plate 5086 in varying thicknesses allows for lightweight strength without compromising durability. This thoughtful approach connects to marine stewardship and underscores economic benefits as lighter boats result in better fuel expenditures and overall performance.

https://www.aluminumplate.net/a/aluminum-plate-for-boat-building-5086-2mm-3mm-4mm.html